Halogen-free, flame-retardant and highly-processable PA6T polyamide resin and preparation method thereof

A polyamide resin and processability technology, which is applied in the field of halogen-free environment-friendly polyamide resin, can solve the problems such as the gap in flame retardancy of PA6T, and achieve the effects of excellent performance, environmental protection and high processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

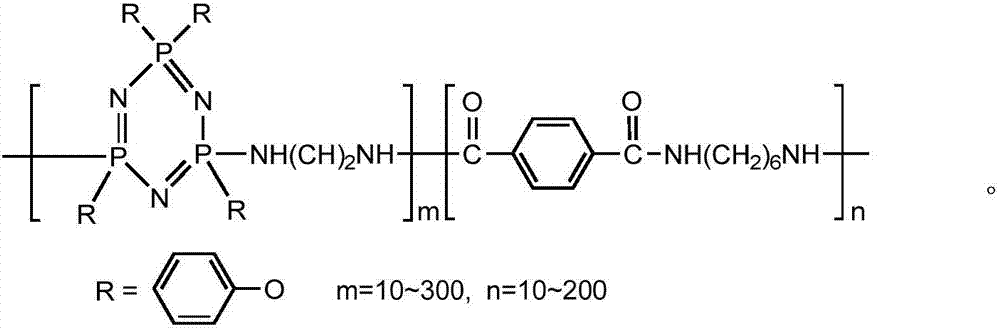

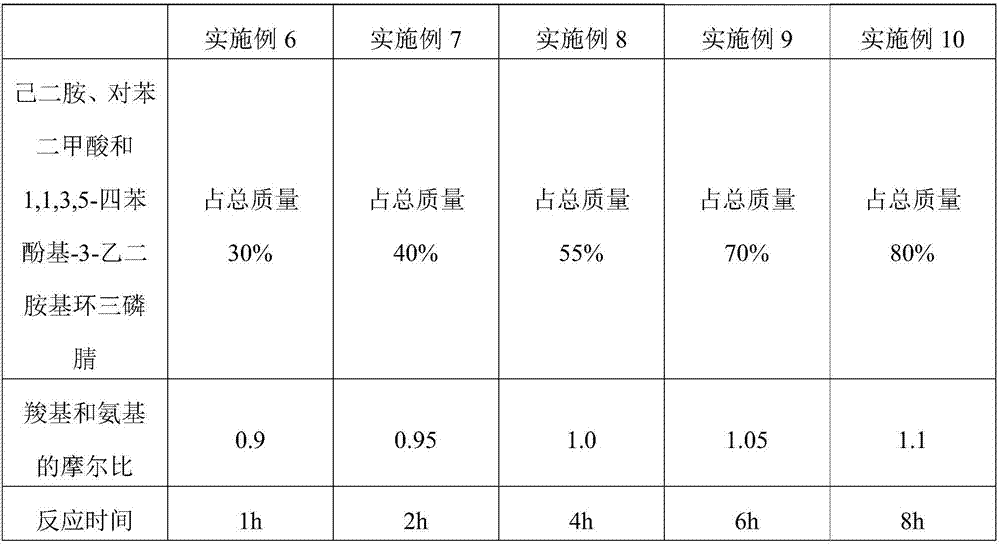

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. Further detailed explanation below by specific embodiment, the formula of embodiment is as shown in the following table:

[0020] (1) Synthesis of reactive flame retardant 1,1,3,5-tetraphenol-3-ethylenediaminocyclotriphosphazene:

[0021]

[0022] (2) Synthesis of PA6T salt

[0023]

[0024]

[0025] (3) Synthesis of PA6T prepolymer

[0026]

Example 11

Example 12

Example 13

Example 14

Example 15

PA6T salt

1500g

2000g

3000g

4000g

5000g

Deionized water

50g

100g

250g

450g

600g

Reaction time

3h

5h

10h

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com