Novel red phosphorus microcapsule and preparation method thereof

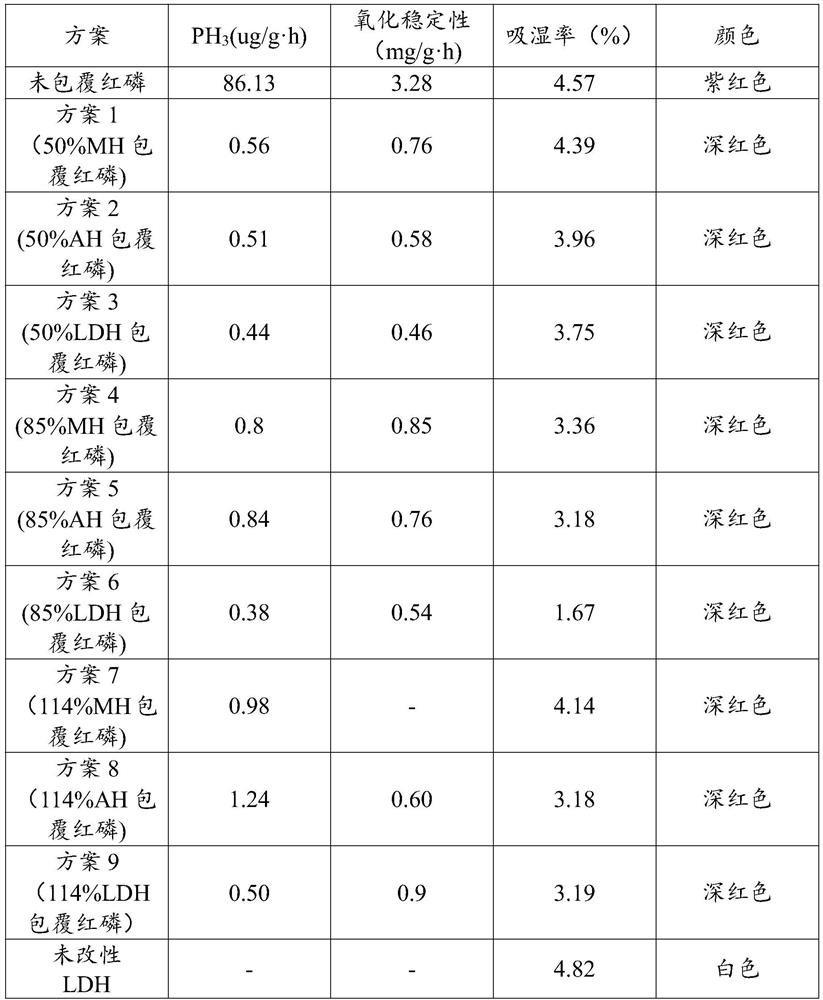

A red phosphorus microcapsule, a new type of technology, applied in the field of flame retardant materials, can solve problems such as low moisture absorption rate, and achieve the effects of low moisture absorption rate, strong alkalinity and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of novel red phosphorus microcapsules:

[0028] (1) Boil deionized water to remove carbon dioxide, weigh 10g of red phosphorus, 15.36g of magnesium nitrate, 7.5g of aluminum nitrate, 0.1g of sodium lauryl sulfate, and 6.4g of sodium hydroxide;

[0029] (2) Put the red phosphorus into a planetary ball mill for ball milling, then add it to deionized water and ultrasonically vibrate for 30 minutes at a frequency of 40 Hz to obtain a stable red phosphorus suspension, which is ready for use;

[0030] (3) nitrate and strong alkali are dissolved in deionized water respectively to obtain 10% nitrate solution and 10% alkali solution;

[0031] (4) adding the nitrate solution and the alkali solution to the reaction vessel, stirring, and keeping the pH stable at 10-11, then adding the red phosphorus suspension and the surfactant to the reaction vessel, stirring for 2 hours to obtain a mixed solution;

[0032] (5) After crystallization and precipitation of th...

Embodiment 2

[0034] The preparation method of novel red phosphorus microcapsules:

[0035] (1) Boil deionized water to remove carbon dioxide, weigh 10g of red phosphorus, 15.36g of magnesium nitrate, 4.84g of iron nitrate, 0.1g of sodium lauryl sulfate, and 6.4g of sodium hydroxide;

[0036] (2) Put the red phosphorus into a planetary ball mill for ball milling, then add it to deionized water and ultrasonically vibrate for 30 minutes at a frequency of 40 Hz to obtain a stable red phosphorus suspension, which is ready for use;

[0037] (3) nitrate and strong alkali are dissolved in deionized water respectively to obtain 10% nitrate solution and 10% alkali solution;

[0038] (4) adding the nitrate solution and the alkali solution to the reaction vessel, stirring, and keeping the pH stable at 10-11, then adding the red phosphorus suspension and the surfactant to the reaction vessel, stirring for 2 hours to obtain a mixed solution;

[0039] (5) After crystallization and precipitation of the m...

Embodiment 3

[0041] The preparation method of novel red phosphorus microcapsules:

[0042] (1) Boil deionized water to remove carbon dioxide, weigh 10g of red phosphorus, 15.36g of magnesium nitrate, 3.65g of nickel nitrate, 0.1g of sodium lauryl sulfate, and 6.4g of sodium hydroxide;

[0043] (2) Put the red phosphorus into a planetary ball mill for ball milling, then add it to deionized water and ultrasonically vibrate for 30 minutes at a frequency of 40 Hz to obtain a stable red phosphorus suspension, which is ready for use;

[0044] (3) nitrate and strong alkali are dissolved in deionized water respectively to obtain 10% nitrate solution and 10% alkali solution;

[0045] (4) adding the nitrate solution and the alkali solution to the reaction vessel, stirring, and keeping the pH stable at 10-11, then adding the red phosphorus suspension and the surfactant to the reaction vessel, stirring for 2 hours to obtain a mixed solution;

[0046] (5) After crystallization and precipitation of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com