Waterborne epoxy hammer paint and preparation method thereof

A technology of water-based epoxy and water-based epoxy resin, applied in the field of coatings, can solve the problems of poor weather resistance, poor construction performance, and poor corrosion resistance of paint films, and achieve the effects of good oil resistance, convenient spraying, and strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

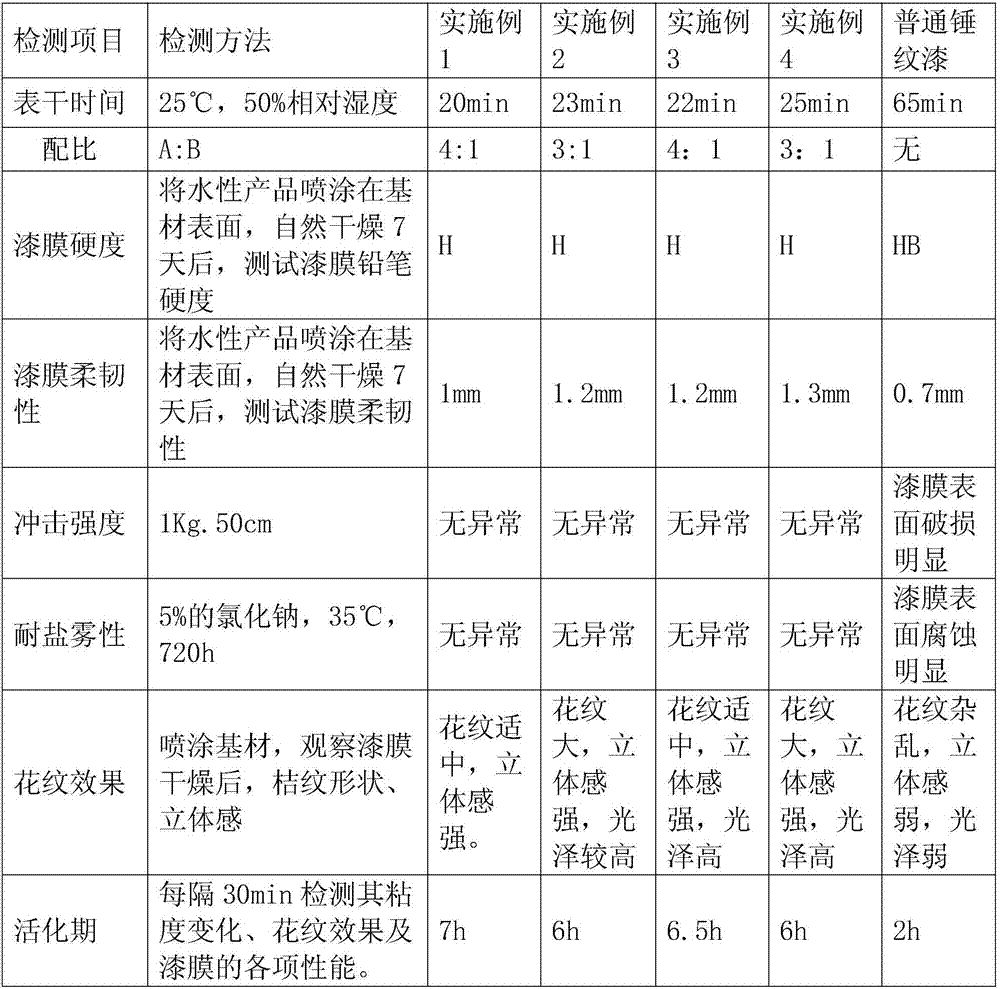

Examples

Embodiment 1

[0030] Weigh component A: 50 parts of water-based epoxy resin, 20 parts of deionized water, 3 parts of cosolvent, 0.3 parts of wetting aid Tego40000, 5 parts of hammering agent, 0.3 parts of thixotropic agent, thickener RM- 1 part of 8W, 0.8 parts of dispersant BYK190, 3 parts of silver powder, 0.8 parts of color paste, 0.3 parts of defoamer BYK028; component B: 65 parts of water-based epoxy curing agent, 25 parts of deionized water; then water-based epoxy resin Put it into the paint mixing tank, then add dispersant, wetting aid and deionized water in sequence, and then stir at high speed, add cosolvent and thixotropic agent under high speed stirring, disperse at high speed, and then prepare the desired color with color paste color, then add thickener and silver powder, stir evenly, reduce the stirring speed, and add hammer pattern agent and defoamer under low speed stirring to obtain component A; then mix the water-based epoxy curing agent and deionized water evenly , to get ...

Embodiment 2

[0032] Weigh component A: 60 parts of water-based epoxy resin, 32 parts of deionized water, 5 parts of cosolvent, 0.8 parts of wetting aid Tego41000, 8 parts of hammering agent, 0.8 parts of thixotropic agent, thickener RHEOLATE299 2 1.5 parts of dispersant BYK194, 5 parts of silver powder, 1.5 parts of color paste, 0.8 parts of defoamer BYK024; B component: 75 parts of water-based epoxy curing agent, 35 parts of deionized water; then add water-based epoxy resin to In the paint mixing tank, add dispersant, wetting aid and deionized water in sequence, then stir at high speed, add cosolvent and thixotropic agent under high speed stirring, disperse at high speed, and then use color paste to prepare the required color, Then add thickener and silver powder, stir evenly, reduce the stirring speed, add hammer pattern agent and defoamer under low-speed stirring, and then get A component; then mix the water-based epoxy curing agent and deionized water evenly, that is Obtain component B...

Embodiment 3

[0034] Weigh component A: 50 parts of water-based epoxy resin, 31.7 parts of deionized water, 3 parts of cosolvent, 0.5 parts of wetting aid Tego40000, 5 parts of hammering agent, 0.3 parts of thixotropic agent, thickener RM- 2 parts of 8W, 1 part of dispersant BYK190, 5 parts of silver powder, 1 part of color paste, 0.5 parts of defoamer BYK028; component B: 70 parts of water-based epoxy curing agent, 30 parts of deionized water; then put the water-based epoxy resin Put it into the paint mixing tank, then add dispersant, wetting aid and deionized water in sequence, and then stir at high speed, add cosolvent and thixotropic agent under high speed stirring, disperse at high speed, and then prepare the desired color with color paste color, then add thickener and silver powder, stir evenly, reduce the stirring speed, and add hammer pattern agent and defoamer under low speed stirring to obtain component A; then mix the water-based epoxy curing agent and deionized water evenly , to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com