Eccentric pin structure

An eccentric pin and eccentric technology, which is applied in the direction of connecting components, rods, bolts, etc., can solve the problems of complex angle adjustment and weak bearing capacity, and achieve high adjustment accuracy, strong bearing capacity, and the effect of avoiding torque loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

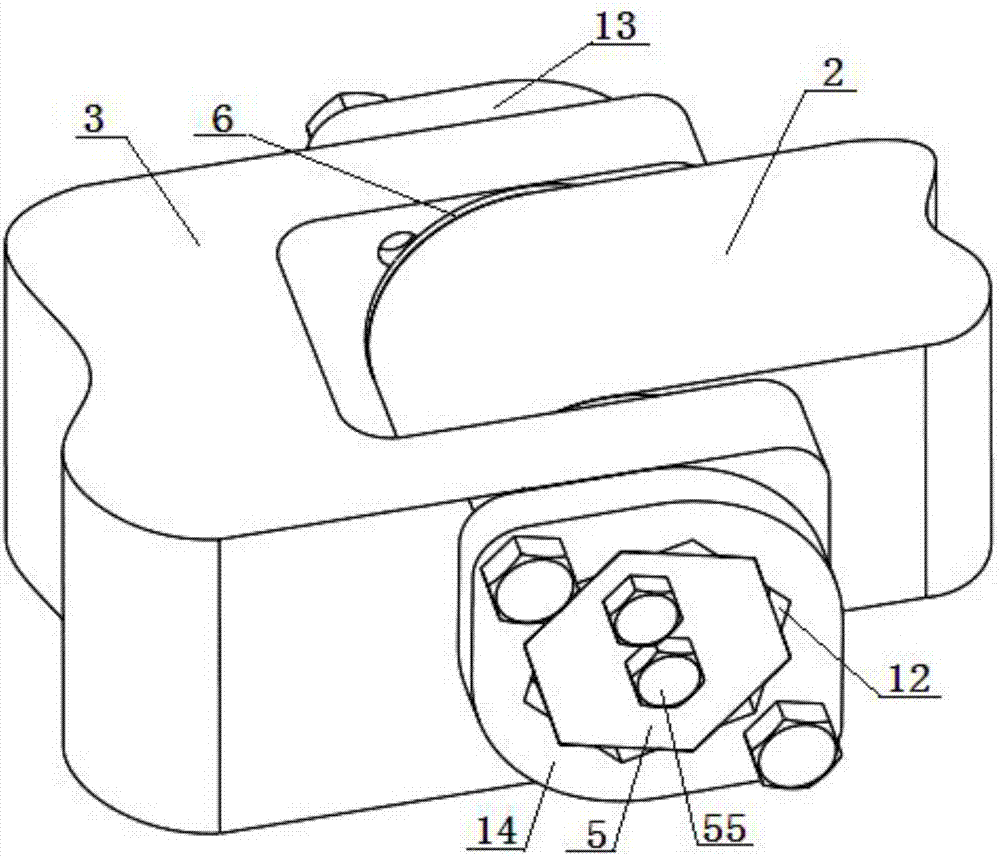

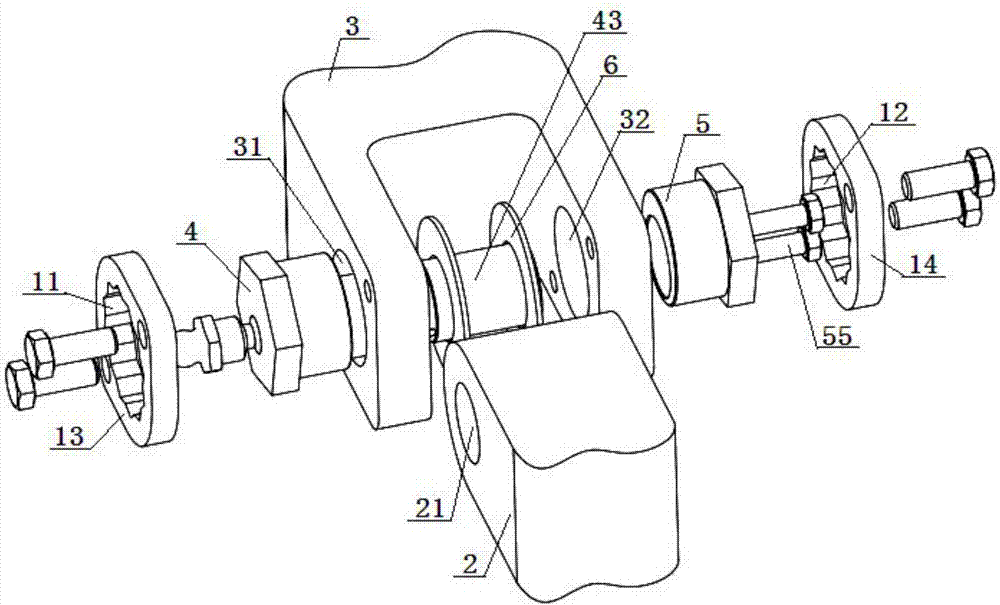

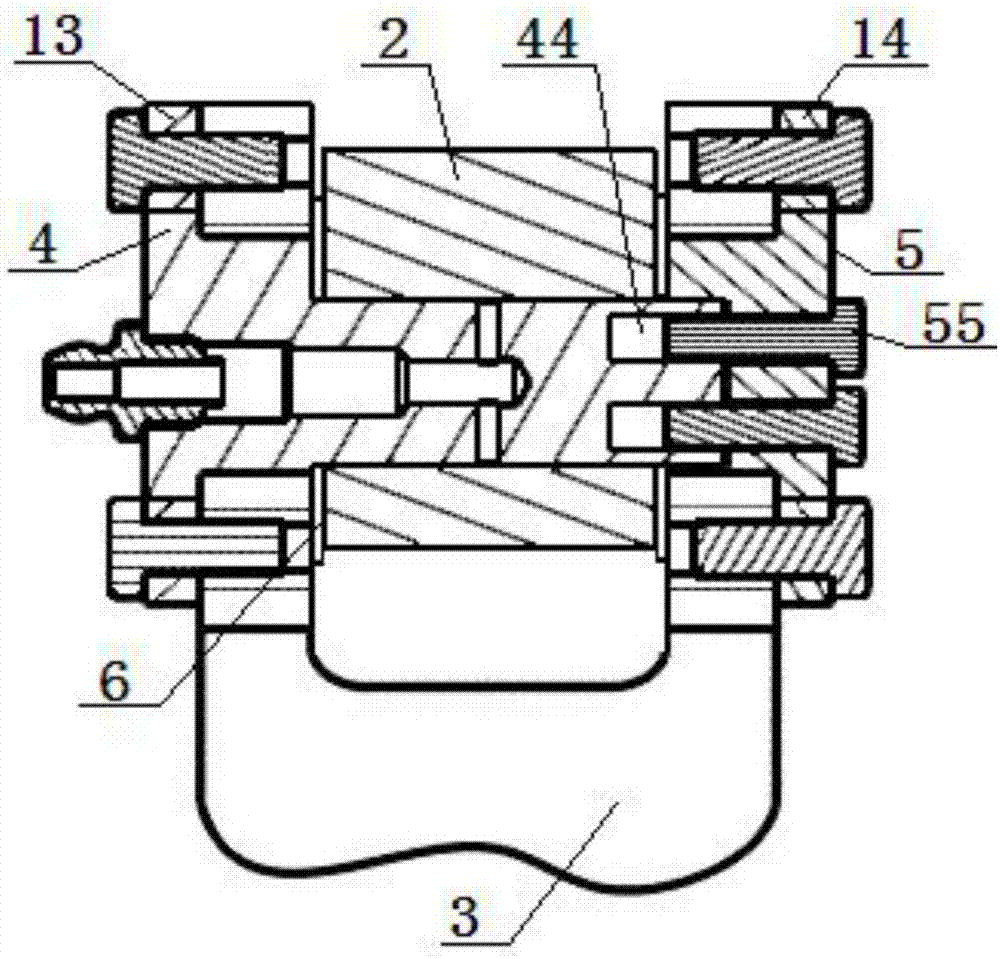

[0059] An eccentric pin structure, comprising a connecting rod 2 and a connecting fork 3, the connecting rod 2 is connected with the connecting fork 3 through an eccentric connection mechanism 1; A pin body fixing hole 31 and a pin cover fixing hole 32 are oppositely arranged; the eccentric connection mechanism 1 includes an eccentric pin 4 and an eccentric pin cover 5, and a second locking pin is provided on the side of the pin cover fixing hole 32 on the connecting fork 3 Hole 12, one end of the eccentric pin cover 5 is limitedly matched with the second locking hole 12, the other end of the eccentric pin cover 5 is inserted into the pin cover fixing hole 32, and the side of the pin body fixing hole 31 on the connecting fork 3 There is a first locking hole 11 in the upper part, and one end of the eccentric pin 4 is limitedly matched with the first locking hole 11, and the other end of the eccentric pin 4 passes through the pin body fixing hole 31 and the pin hole 21 in sequenc...

Embodiment 2

[0062] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0063] The eccentric pin 4 includes a locking cap 41, a pin seat 42 and a pin body 43 of an integral structure, the locking cap 41 is fixedly connected with the pin body 43 through the pin seat 42, and the locking cap 41 is the same as the pin seat 42. Shaft setting, the distance between the central axis of the pin body 43 and the central axis of the pin seat 42 is a millimeter, and a is greater than zero;

[0064] The locking cap 41 is limitedly matched with the first locking hole 11, the pin seat 42 is inserted into the pin body fixing hole 31, and the end of the pin body 43 near the pin seat 42 is inserted into the pin hole 21. The end of the pin body 43 far away from the pin seat 42 is fixedly connected with the eccentric pin cover 5 through a fixing bolt 55, and the diameter of the pin body 43 is 60 mm; the eccentric pin cover 5 includes a locking cover 51 and a pin cover seat 52 of an int...

Embodiment 3

[0066] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0067] The first locking hole 11 is opened on the first locking plate 13, and the first locking plate 13 is fixedly connected with the connecting fork 3 by at least two bolts; the second locking hole 12 is opened on the second On the locking disc 14, the second locking disc 14 is fixedly connected to the connecting fork 3 by at least two bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com