Button switch assembly machine

A technology for assembling machines and buttons, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of low efficiency of manual assembly button speed control switches, and the quality is greatly affected by the level of operators, so as to improve continuity, improve efficiency, Avoid the effect of loose buttons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

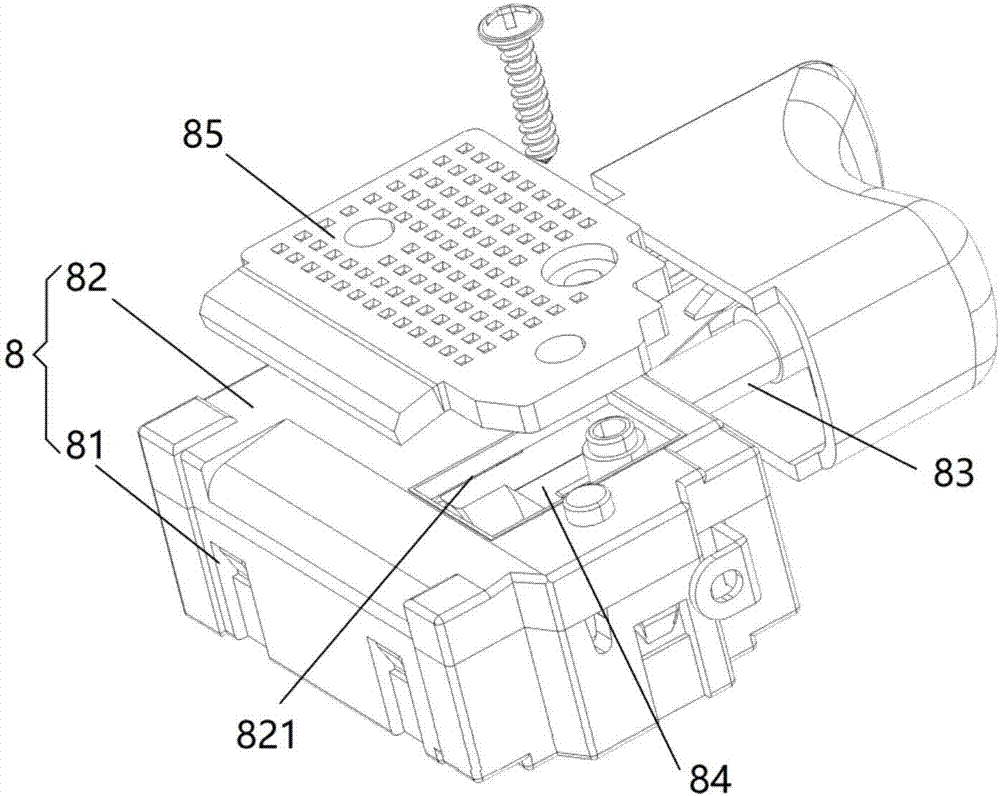

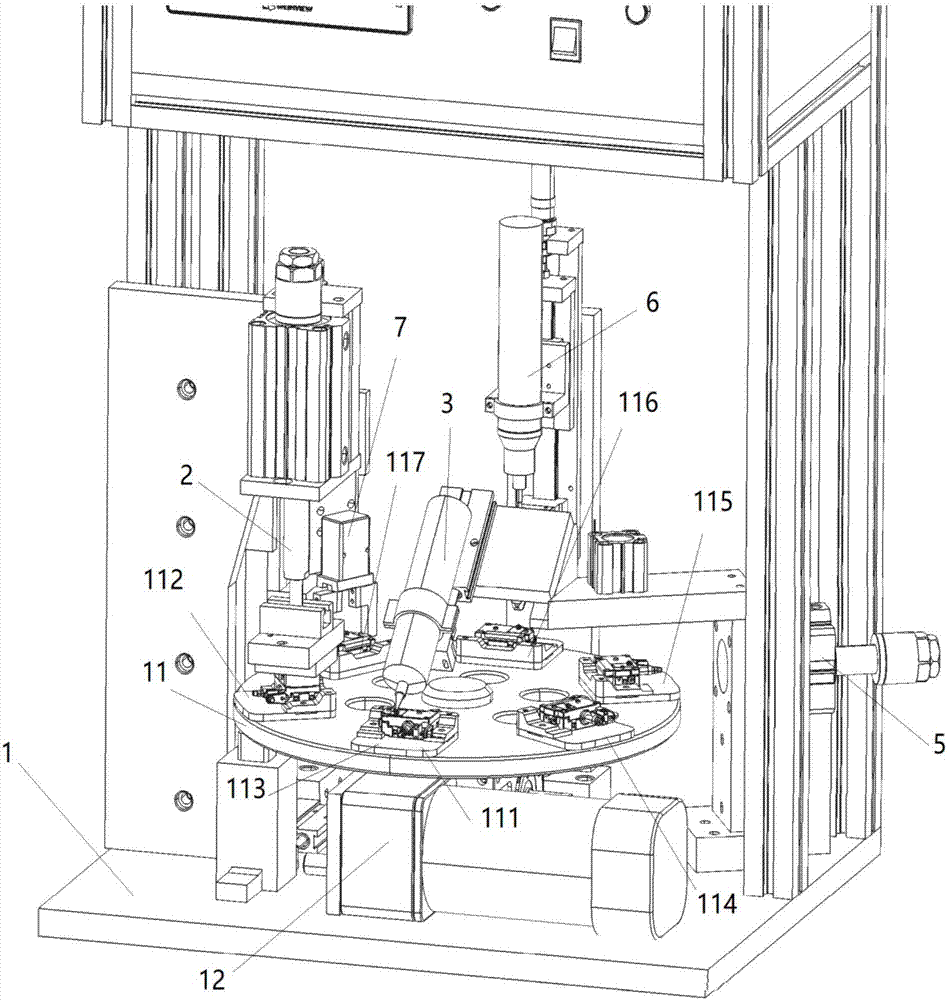

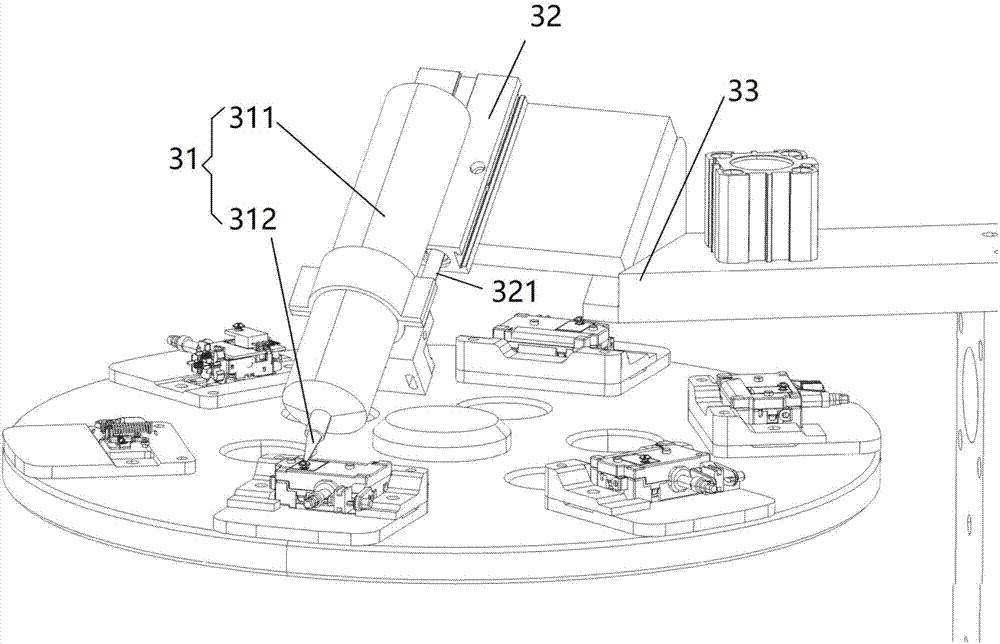

[0047] This embodiment provides a button switch assembly machine, its structure is as follows Figure 2 to Figure 5 shown. Such as figure 1 As shown, the button switch suitable for assembly by the button switch assembly machine provided by this embodiment includes a housing 8 and a button structure 83 installed on the housing 8, and the button structure 83 includes a part protruding from the base installed on the base 81 81 push rod, and the button installed on the end of the push rod away from the base 81; the housing 8 includes a base 81 and a cover 82 that can be connected to the base 81; A heat dissipation hole 821 is opened at the position; the push button switch also includes a heat dissipation structure 85 that is located at the position of the cover plate corresponding to the heat dissipation hole 821 and is in contact with the semiconductor element 84. The heat dissipation structure 85 and the cover body 82 They are connected by fasteners, and thermal conductive glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com