A grinding method for a circular arc-shaped blade edge

A technology of arc-shaped blades, which is applied in the field of grinding of arc-shaped blade blades, can solve problems such as inability to process blades, and achieve the effects of good blade angle consistency, high surface finish, and good arc shape of the blade surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

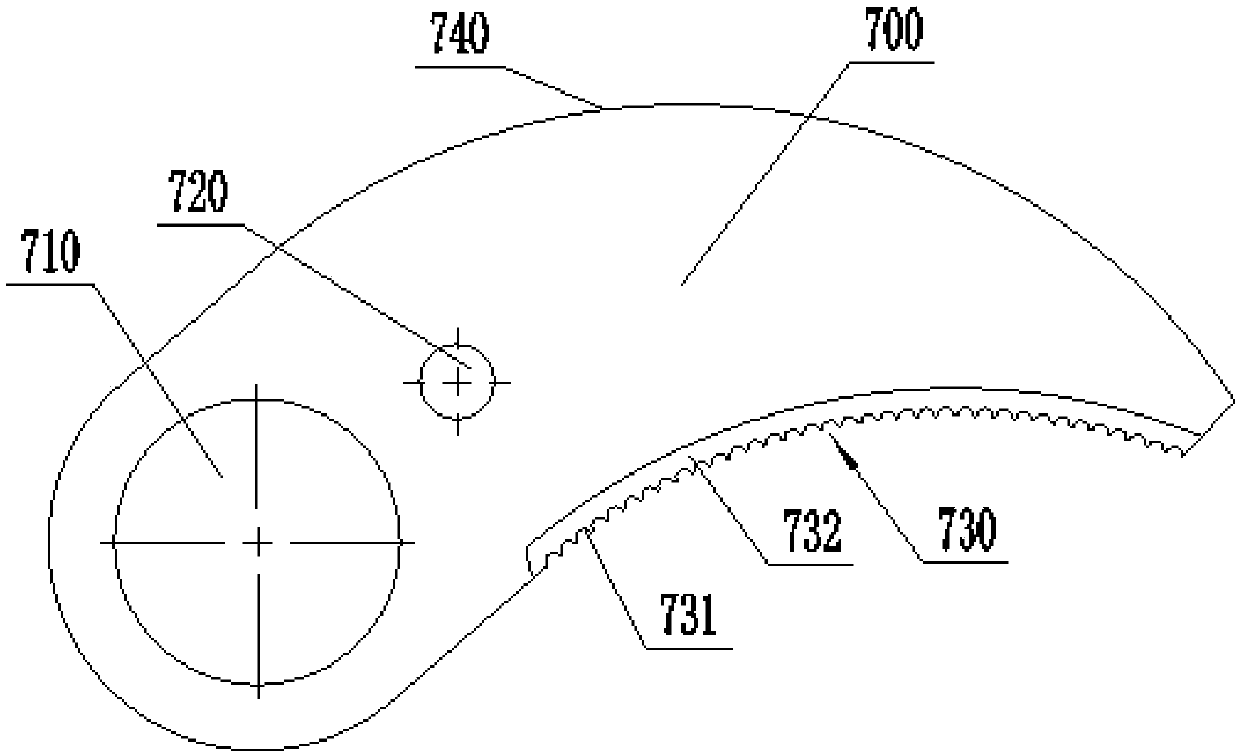

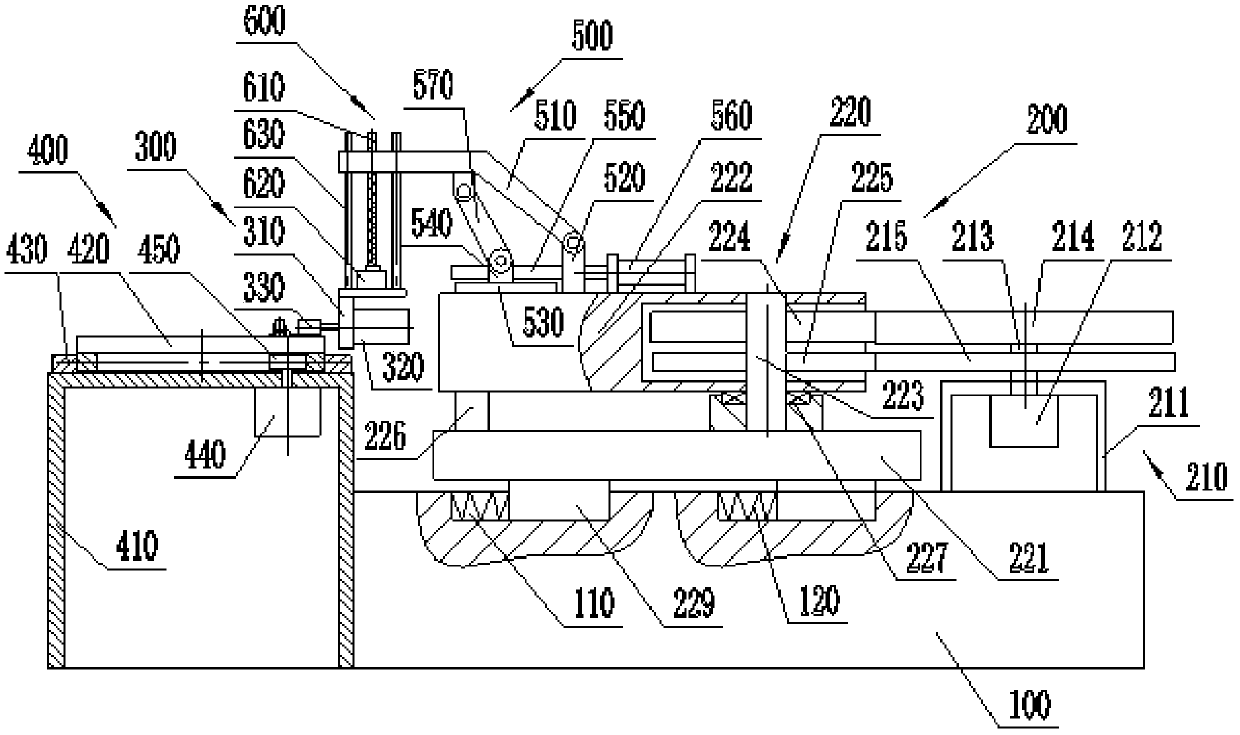

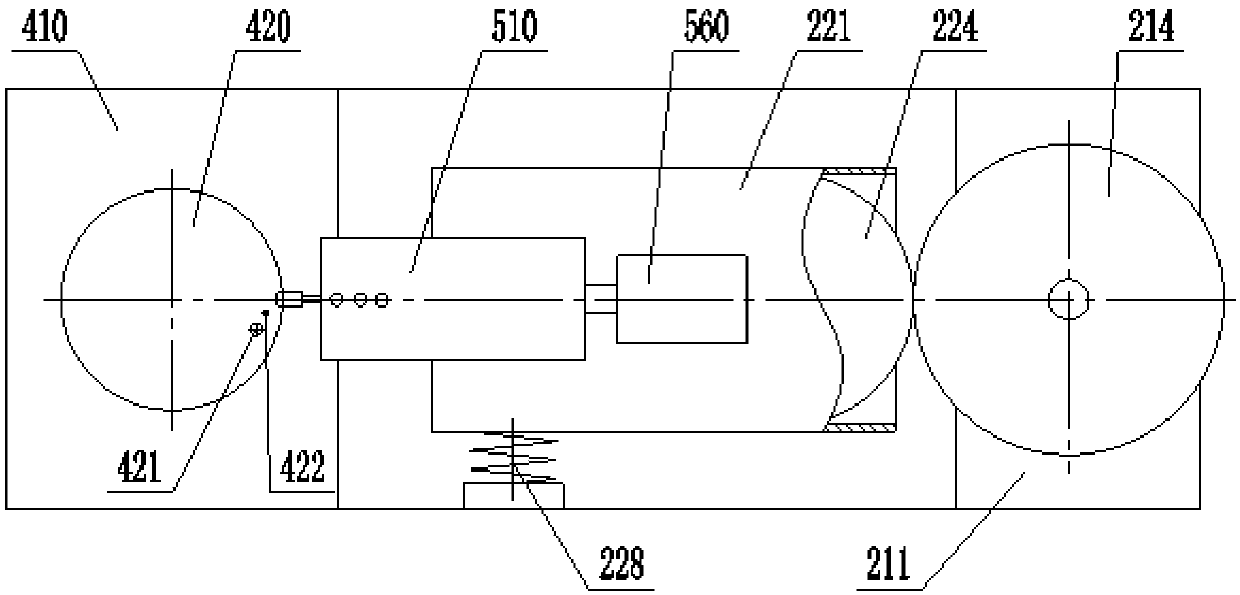

[0058] Such as figure 2 , image 3 As shown, a kind of arc-shaped blade grinding device of this embodiment mainly completes the figure 1 The grinding process of the arc-shaped blade blade shown in this circular-arc-shaped blade has a circular mounting hole 710 at one end of the knife body 700 for installing the blade on the corresponding cutting equipment, and the knife body 700 is close to the mounting hole 710 There is a positioning hole 720 at the position of the blade, which is used for positioning when installing the blade; the other two sides of the blade body 700 are the blade side 730 and the blade back side 740 respectively, both of which are arc-shaped, but not concentric, and gradually retract toward the front end of the blade. narrow, and there are knife teeth 731 distributed on the arc segment of the blade side 730, and the front and back sides of the knife teeth 731 are blade slopes 732. In actual production, the blade slope 732 needs to be ground, and the blad...

Embodiment 2

[0070] The grinding method of a kind of circular-arc-shaped blade edge of the present embodiment, it adopts the grinding device among the embodiment 1 to such as figure 1 The arc-shaped insert shown is ground, grinding the bevel 732 of the edge. The specific steps of the operation will be described in detail below.

[0071] 1. Blade installation

[0072] Install the arc-shaped blade to be ground on the workbench assembly 400 . Specifically: first, align the mounting hole 710 and the positioning hole 720 of the arc-shaped blade with the fixed shaft 421 and the positioning pin 422 on the turntable 420 respectively, put down the arc-shaped blade, and position it; then, place the pressing spring Sleeve on the fixed shaft 421, tighten the compression nut, and fix the arc-shaped blade, and then complete the installation of the blade.

[0073] 2. Grinding angle adjustment

[0074] First, select three grinding wheels 330, which are respectively rough grinding wheels, semi-finishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com