Polishing and cleaning system and method for inner wall of copper tube

A cleaning system and technology for copper pipes, applied in cleaning methods and utensils, cleaning hollow objects, machine tools for surface polishing, etc., can solve the problems of inability to polish the inner wall of copper pipes and low polishing efficiency, and achieve a uniform surface. High processing and polishing efficiency, avoiding inconsistent polishing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

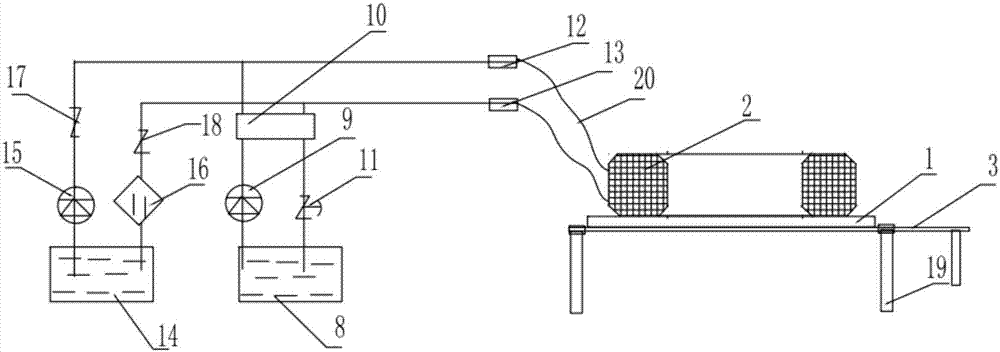

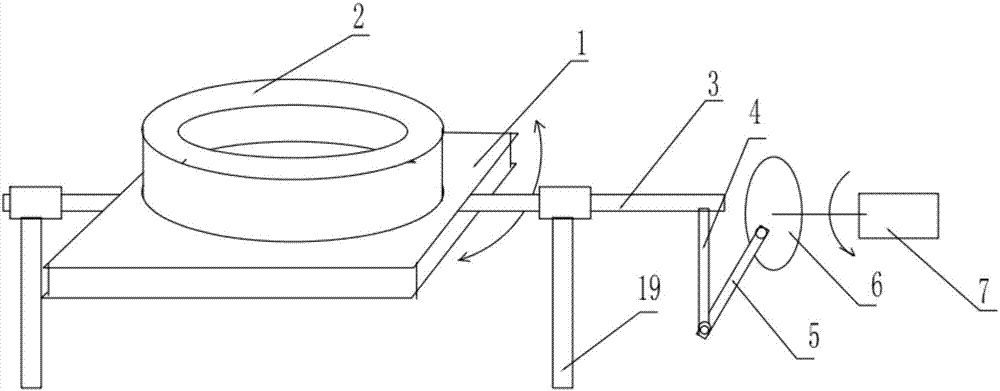

[0030] if Figure 1 to Figure 3 As shown, the present invention aims at the deficiencies of the above-mentioned prior art, and provides a copper tube inner wall polishing and cleaning system capable of processing the entire copper tube.

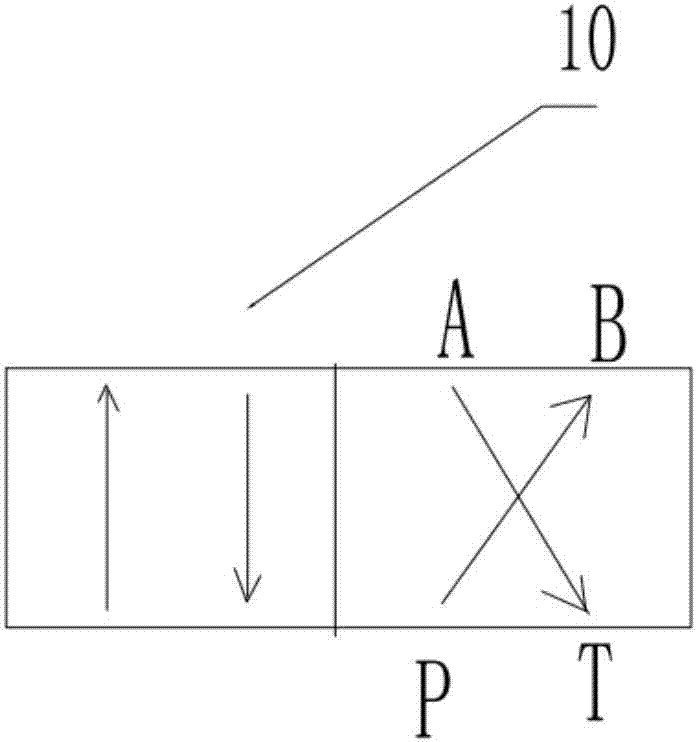

[0031] The technical scheme of the present invention to solve the above-mentioned technical problems is as follows: a copper pipe inner wall polishing and cleaning system, including a coil platform 1 and a polishing circulation device, and the polishing circulation device includes a polishing liquid tank 8, a high-pressure pump 9, a reversing valve 10 and Pressure regulating valve 11, the reversing valve 10 includes a main liquid inlet P, a main liquid return port T, a working liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com