Oil way system of closed type transmission mechanism

A technology of oil circuit system and transmission mechanism, applied in transmission parts, mechanical equipment, belts/chains/gears, etc., can solve the problems of increasing the wear of sliders and slide rails, waste of resources, and cumbersomeness, so as to avoid loss and overflow. , the effect of reducing temporary space and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described with reference to the following examples, and the content mentioned in the embodiments is not a limitation of the present invention.

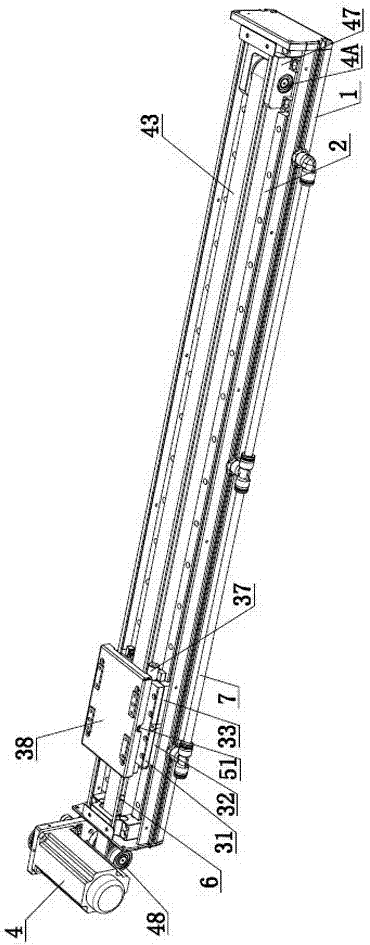

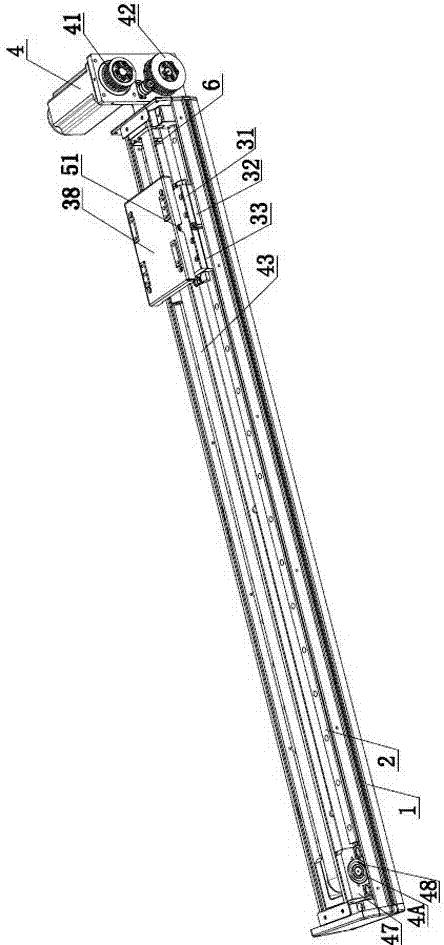

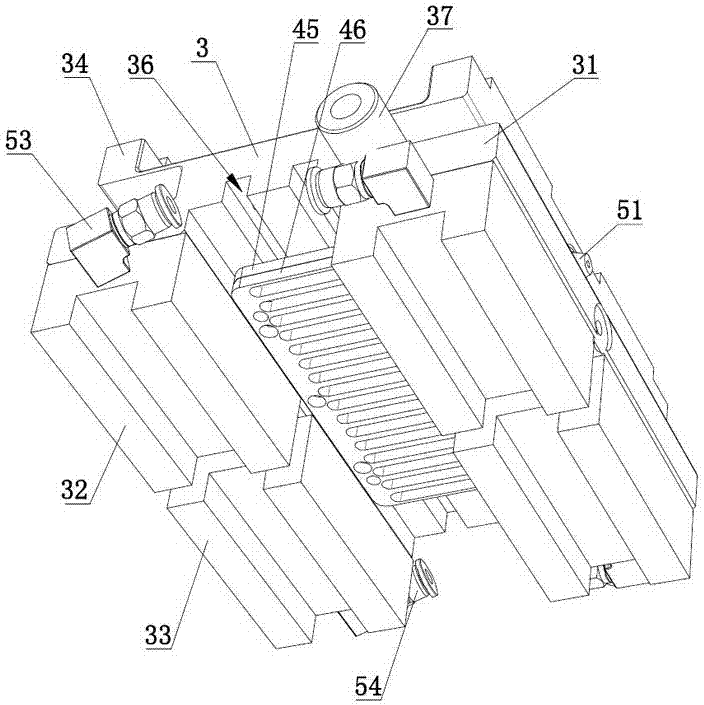

[0025] Such as Figure 1 to Figure 6 Shown is the first embodiment of an oil circuit system of a closed transmission mechanism of the present invention, which includes a base 1, a guide rail installed on the base 1, a sliding seat 3 provided on the guide rail 2, and a drive that drives the sliding seat 3 to move back and forth Mechanism, both sides of the sliding seat 3 are equipped with mounting seats 31, and the mounting seats 31 on both sides are equipped with a first sliding block 32 and a second sliding block 33, which are used to provide the first sliding block 32 and The oil path system 5 provided by the second slider 33 and the sliding table 34 installed on the sliding seat 3; the oil path system 5 includes a first oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com