Floating transportation device and method for major diameter underwater water pipes

A water pipeline, large-diameter technology, used in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the problems of increasing construction costs, large wind and waves, and inconvenient construction, reducing the total time. , the effect of reducing the number and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

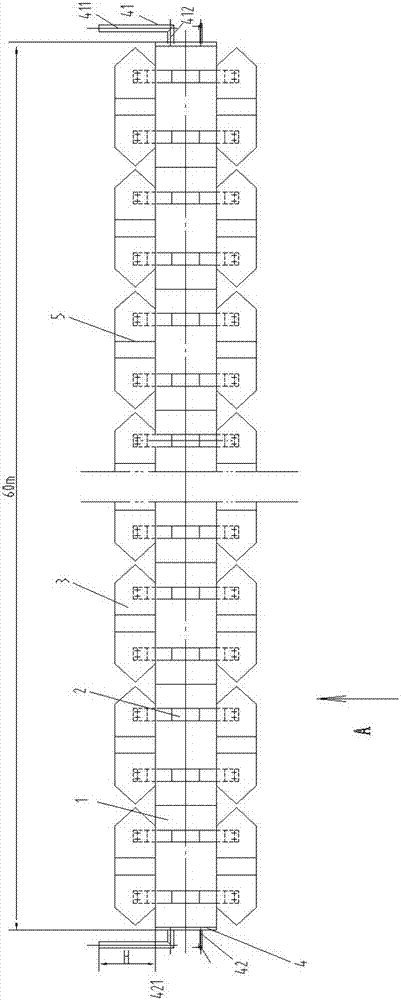

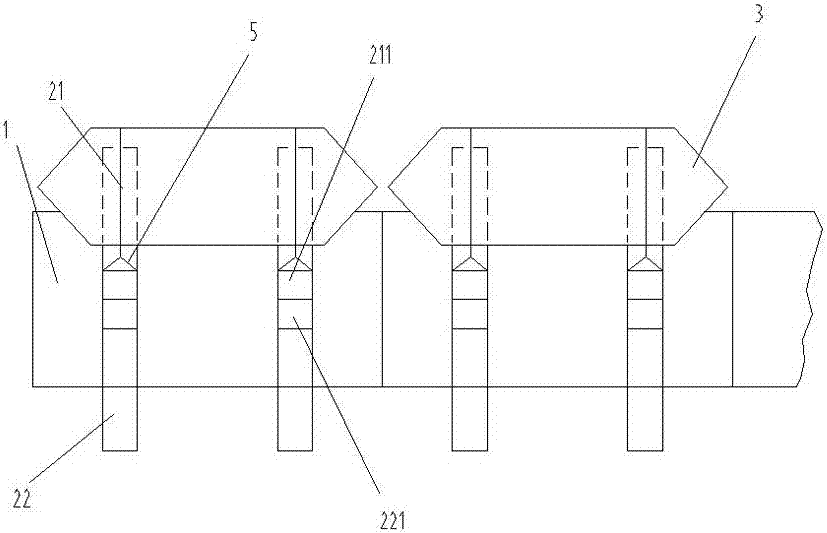

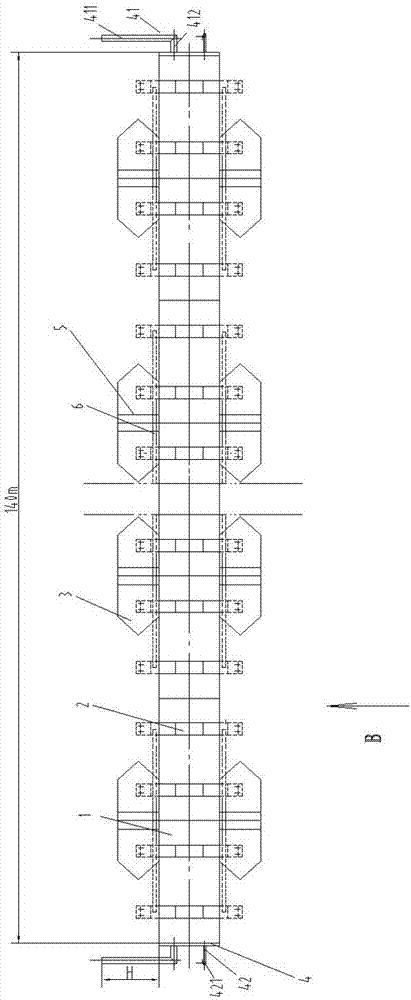

[0042] The present invention will be further described below in conjunction with the accompanying drawings and an embodiment of a power plant's underwater circulating cooling water supply pipe.

[0043] The water intake pipe of the circulating cooling water supply pipeline of a power plant is spliced by HDPE pipes with an inner diameter of 2.6m. Two pipelines are set up with a total length of about 825m. The average excavation depth of the foundation trench 10 is about 7m, and the excavation width at the bottom is 11m. The excavation slope is 1:2. The length of the east line of the sea water intake is about 200m.

[0044] Such as Figure 1 to Figure 6 As shown, this embodiment includes connecting 10 HDPE pipes 1 with a standard length of 6m to form a section of water delivery pipeline with a length of 60m, and 23.3 HDPE pipes 1 to form a section of water delivery pipeline with a length of 140m. Water pipes, multiple counterweights 2 and multiple airbags 3, multiple counter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com