Methanol-to-olefin catalyst and preparation method thereof

A technology of methanol to olefins and catalysts, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as catalyst loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to the parts by weight, 30 parts of SAPO-34 molecular sieves, 20 parts of kaolin, 30 parts of aluminum sol and 30 parts of deionized water are fully mixed and stirred at high speed for 1 hour to form a mixed solution I, and 2.5% of its weight is added to the mixed solution I Nano-titanium silicate was stirred and sheared at high speed for 30 minutes to form a suspension. The average particle size of the suspension particles was measured by a laser particle size analyzer to be 4.1 μm. Spray dry the suspension, the atomizer frequency is 25HZ, the air inlet temperature is 340°C, and the air outlet temperature is 200°C, collect the solids at the bottom of the drying tower, use a 60-mesh standard sieve to remove the large particles, and finally put the catalyst in the muffle furnace. The temperature was raised to 600° C. within 8 hours, and then roasted at a constant temperature at 600° C. for 8 hours to obtain a finished microspherical catalyst with an average par...

Embodiment 2~9

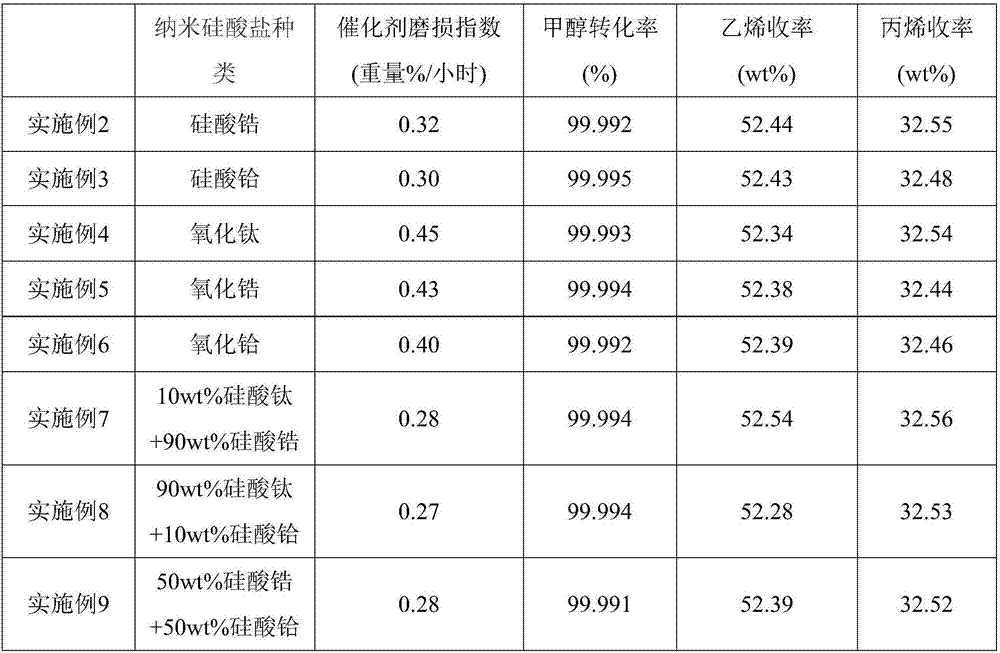

[0033] The operation steps and experimental conditions are exactly the same as in Example 1, but the oxides or nanosilicates of the elements in Group IVB of the periodic table are changed, and the obtained catalyst wear index and catalyst evaluation results are shown in Table 1.

[0034] Table 1

[0035]

Embodiment 10~14

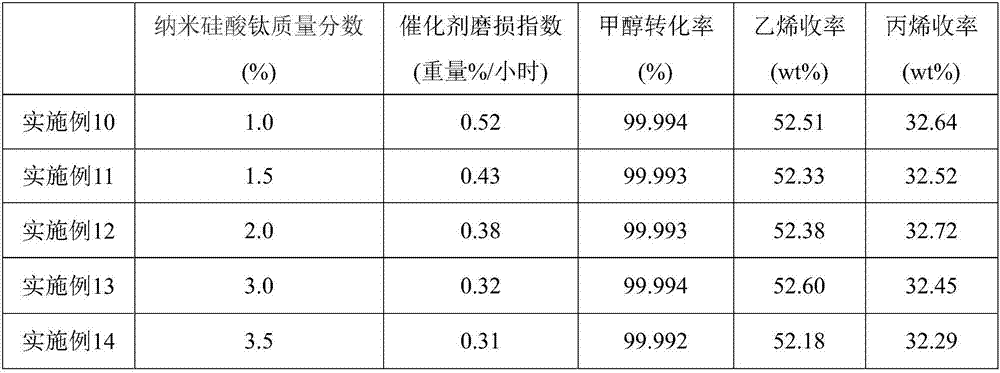

[0037] The operation steps and experimental conditions are exactly the same as in Example 1, but the mass fraction of nano-titanium silicate is different. The wear index and catalyst activity evaluation results of the catalyst obtained by spray drying are shown in Table 2.

[0038] Table 2

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com