A multipurpose rock crusher for civil engineering

A technology of civil engineering and stone crusher, applied in the direction of using liquid separation agent, separation method, and separation of dispersed particles, which can solve the problems of inconvenient replacement of internal devices, poor stone crushing effect, and narrow use range, so as to increase the use range, Prevent stones from splashing and improve the efficiency of crushing stones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

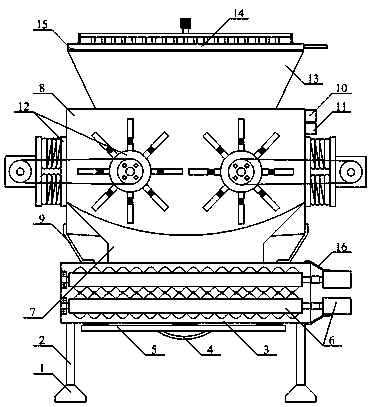

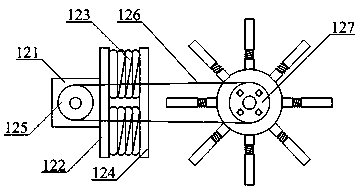

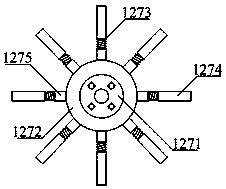

[0042] as attached figure 1 to attach Figure 5 shown

[0043]The present invention provides a multi-purpose civil engineering stone crusher, which includes a foot base 1, a support column 2, a powder box 3, a handle 4, a discharge door 5, a crushing roller structure 6, a hopper 7, a gravel box 8, Support plate 9, primary switch 10, secondary switch 11, buffer gravel driving machine structure 12, feed hopper 13, sprinkler head structure 14, connecting shaft 15 and connecting plate 16, and the described foot seat 1 is screwed on the support The lower end of the column 2; the supporting columns 2 are respectively longitudinally welded at the four corners of the bottom of the powder box 3; the handle 4 is screwed to the lower middle position of the discharge door 5; the hinge of the discharge door 5 is installed At the front side of the bottom outlet of the powder box 3; the crushing roller structure 6 is installed in pairs transversely inside the powder box 3; the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com