A vanadium battery based triazine derivative diaphragm and preparation method thereof

A technology of triazine derivatives and vanadium batteries, applied in fuel cells, electrochemical generators, regenerative fuel cells, etc., can solve the problems of human body and environmental hazards, anti-ultraviolet aging chemical stability, poor vanadium resistance, and environmental protection , to achieve the effect of low price, good anti-ultraviolet aging and alkali resistance, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

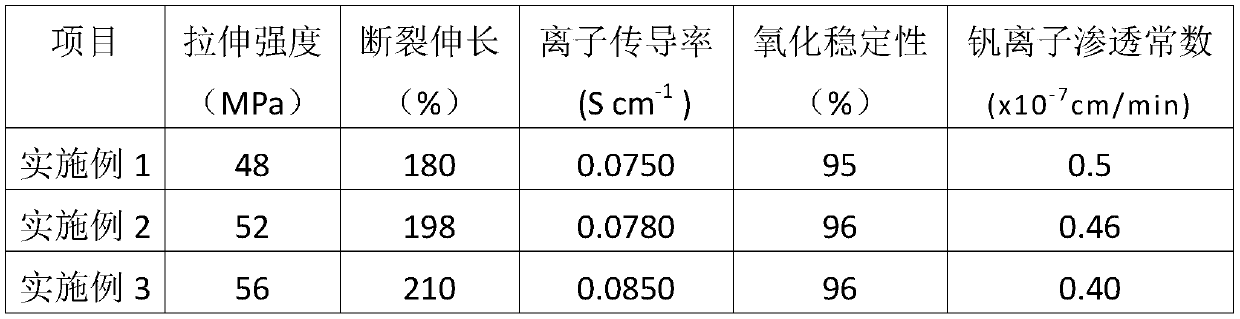

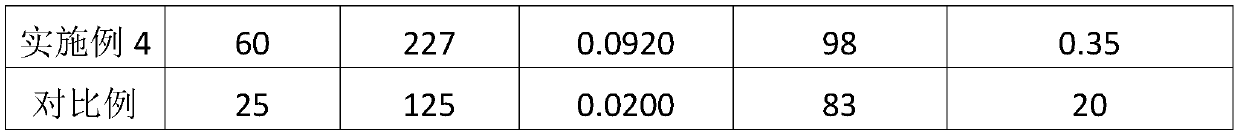

Embodiment 1

[0029] A preparation method based on a triazine derivative diaphragm for a vanadium battery, comprising the steps of:

[0030] 1) Preparation of polymeric triazine derivatives: 10 g of 2,4-diamino-6-phenyl-1,3,5-triazine and 35 g of 2-chloroethyl vinyl ether were added to 100 g of acetonitrile and mixed Evenly, stir and reflux at 30°C for 6 hours, then remove the solvent by rotary evaporation at 40°C, then wash with ether and ethyl acetate for 3 times, and finally remove the solvent by rotary evaporation at 40°C;

[0031] 2) Preparation of polymer film: 3 g of polymerized triazine derivatives prepared in step 1), 2 g of acrylonitrile, 2 g of perfluoro-n-propyl vinyl ether, 0.05 g of sodium dodecylbenzenesulfonate and benzoin Mix 0.1g of diethyl ether, drop it on a glass plate, put it under a 200nm ultraviolet lamp under a nitrogen atmosphere and illuminate it for 45 minutes, a polymerization reaction occurs, and a polymer film is obtained;

[0032] A triazine derivative-based...

Embodiment 2

[0035] A preparation method based on a triazine derivative diaphragm for a vanadium battery, comprising the steps of:

[0036] 1) Preparation of polymeric triazine derivatives: 10 g of 2,4-diamino-6-phenyl-1,3,5-triazine and 37 g of 2-chloroethyl vinyl ether were added to 110 g of diethyl ether and mixed Uniform, stirred and refluxed at 33°C for 7 hours, then removed the solvent by rotary evaporation at 43°C, washed with ether and ethyl acetate for 4 times, and finally removed the solvent by rotary evaporation at 44°C;

[0037] 2) Preparation of polymer film: 3.3 g of polymerized triazine derivatives prepared in step 1), 4 g of styrene, 3 g of perfluoro-n-propyl vinyl ether, 0.06 g of polyoxypropylene polyvinyl glyceryl ether and benzoin Mix 0.13g of dimethyl ether, drop it on a glass plate, put it under a 220nm ultraviolet lamp under an argon atmosphere and illuminate it for 48 minutes, a polymerization reaction occurs, and a polymer film is obtained;

[0038] A triazine der...

Embodiment 3

[0041] A preparation method based on a triazine derivative diaphragm for a vanadium battery, comprising the steps of:

[0042] 1) Preparation of polymeric triazine derivatives: 10 g of 2,4-diamino-6-phenyl-1,3,5-triazine and 38 g of 2-chloroethyl vinyl ether were added to 113 g of acetone and mixed Evenly, stir and reflux at 38°C for 8 hours, then remove the solvent by rotary evaporation at 48°C, then wash with ether and ethyl acetate for 5 times, and finally remove the solvent by rotary evaporation at 48°C;

[0043]2) Preparation of polymer film: 3.8 g of polymerized triazine derivatives prepared in step 1), 4.5 g of α-methylstyrene, 3.5 g of perfluoro-n-propyl vinyl ether, nonylphenol polyoxygen Mix 0.07g of vinyl ether and 0.18g of benzoin isopropyl ether, drop it on a glass plate, put it under a 240nm ultraviolet lamp under a neon gas atmosphere, and illuminate it for 55 minutes to undergo a polymerization reaction to obtain a polymer film;

[0044] A triazine derivative-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com