Manufacturing method of electrical connector

An electrical connector, glass insulation technology, applied in the direction of connection, assembly/disassembly of contacts, circuit/collector parts, etc., can solve the problem of reduced metal-glass-ceramic sealing performance, unsatisfactory bonding effect, and easy aging Deformation and other problems, to achieve the effect of reducing the possibility of air leakage, excellent high temperature and high pressure resistance, and not easy to age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

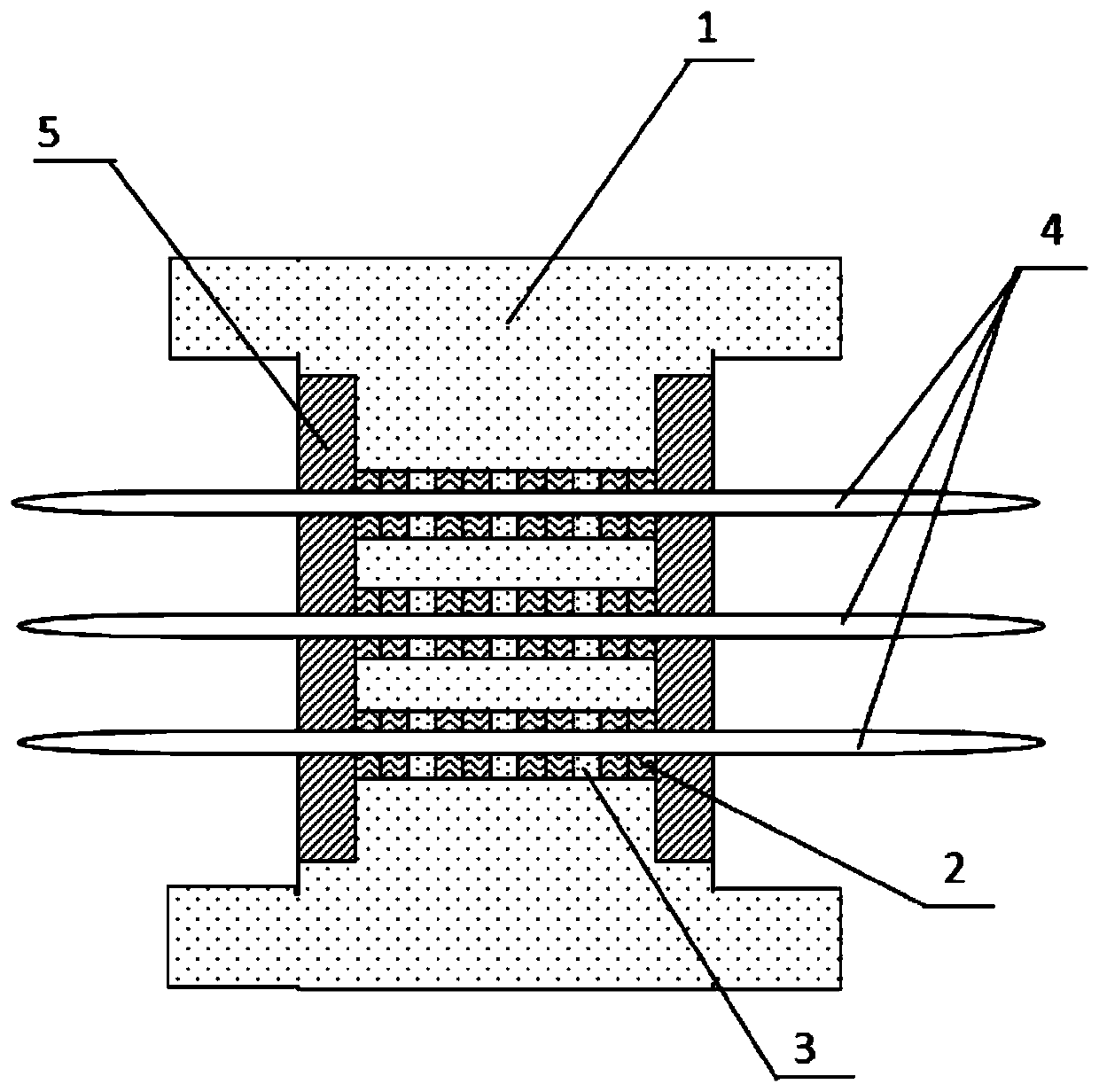

[0029] A method for preparing an electrical connector, comprising the steps of:

[0030] Step 1. Assemble the metal shell with the sealing hole on the sealing mold, then put the glass insulating tube and the ceramic insulating tube into the sealing hole at intervals in sequence, and then put the conductor pin into the glass insulating tube and the ceramic insulating tube after pressing tightly. In the ceramic insulating tube; the two ends of the sealing hole of the metal shell are provided with grooves;

[0031] Step 2. Seal the structure assembled in step 1 with a sealing mold box, sinter in a high-temperature sintering furnace at 980° C., and obtain an initial electrical connector after sintering; treat the initial electrical connector with an oxide layer;

[0032] Step 3: Fill the grooves at both ends of the sealing hole of the initial electrical connector with high-temperature-resistant insulating glue, and cure at room temperature for 12 to 24 hours to form an insulating ...

Embodiment 2

[0038] A method for preparing an electrical connector, comprising the steps of:

[0039]Step 1. Assemble the metal shell with the sealing hole on the sealing mold, then put the glass insulating tube and the ceramic insulating tube into the sealing hole at intervals in sequence, and then put the conductor pin into the glass insulating tube and the ceramic insulating tube after pressing tightly. In the ceramic insulating tube; the two ends of the sealing hole of the metal shell are provided with grooves;

[0040] Step 2. Seal the structure assembled in step 1 with a sealing mold box, and sinter it in a high-temperature sintering furnace at 1000 ° C. After sintering, the initial electrical connector is obtained; the initial electrical connector is treated with an oxide layer;

[0041] Step 3: Fill the grooves at both ends of the sealing hole of the initial electrical connector with high-temperature-resistant insulating glue, and cure at room temperature for 12 to 24 hours to form...

Embodiment 3

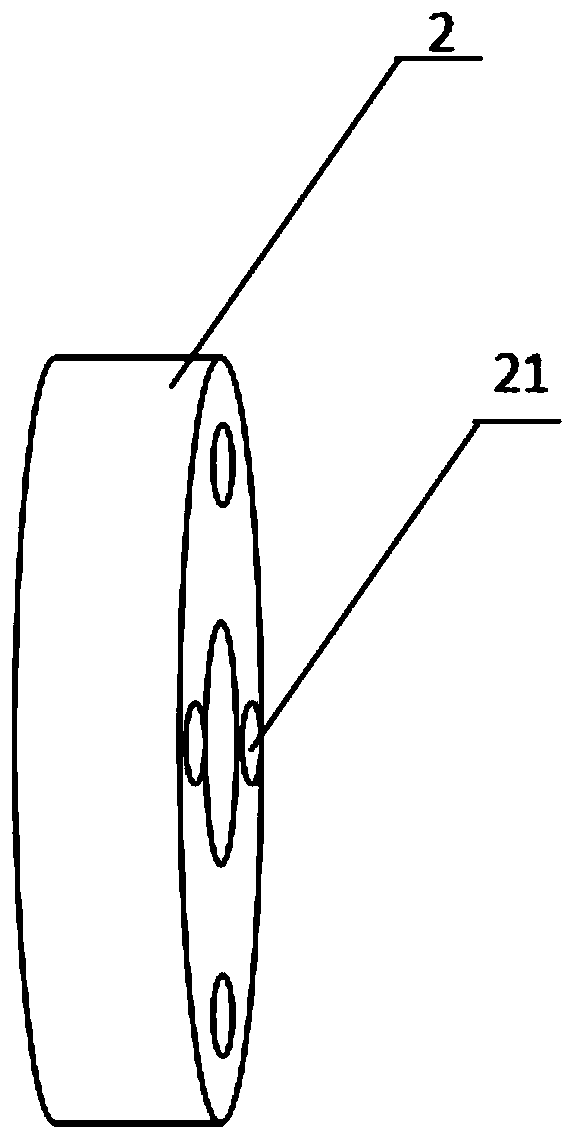

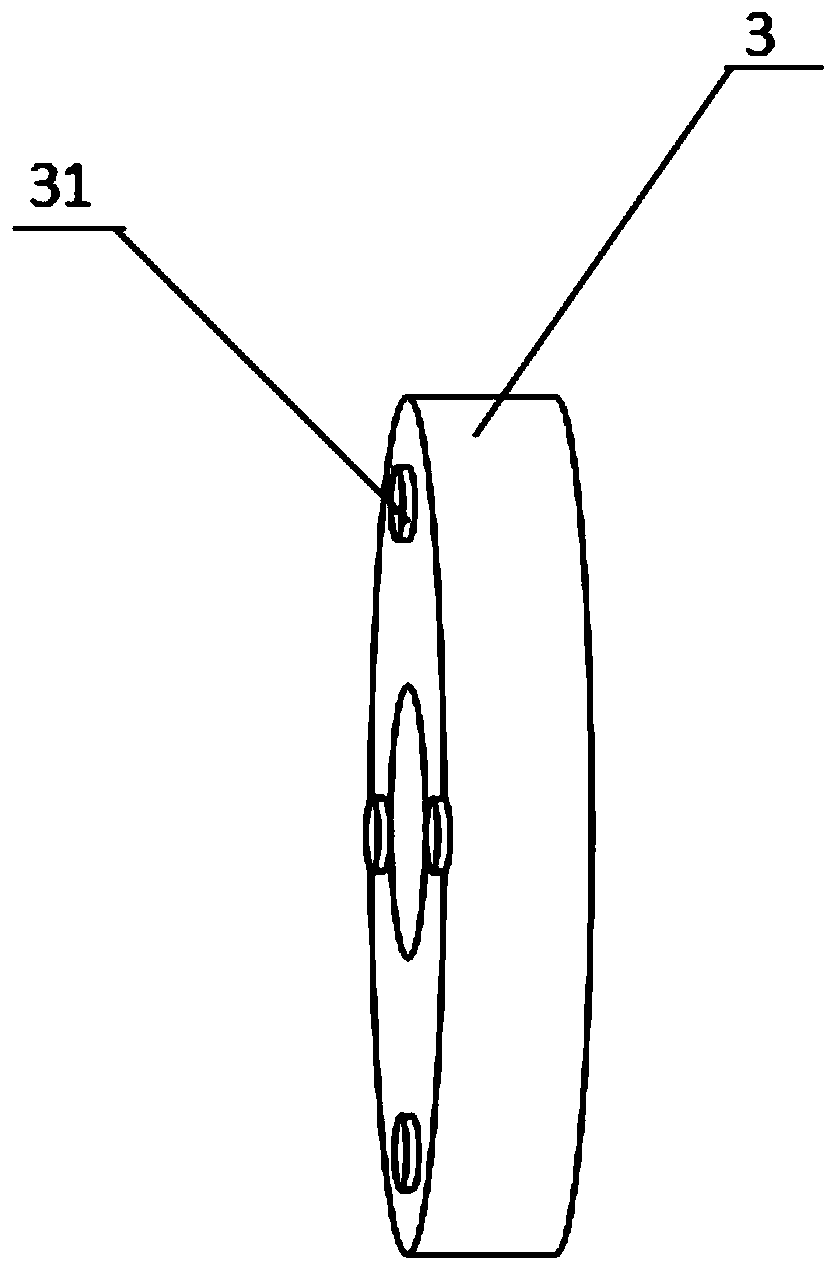

[0047] The sizes of the glass insulating tubes and the ceramic insulating tubes are the same; the order in which the glass insulating tubes 2 and the ceramic insulating tubes 3 are sequentially inserted into the sealing holes is as follows: 2 glass insulating tubes and 1 ceramic insulating tube , 2 glass insulating tubes and 1 ceramic insulating tube; the tubes repeat the above loading sequence until the sealing holes are filled; figure 2 and image 3 As shown, the side wall of the glass insulating tube 2 in contact with the ceramic insulating tube 3 is uniformly provided with a plurality of depressions 21; the side wall of the ceramic insulating tube 3 in contact with the glass insulating tube 2 is evenly provided with A plurality of concave portions 21 are matched with convex portions 31 . In this way, by increasing the concave-convex joint structure of the glass insulating tube and the ceramic insulating tube, the bonding degree of the glass and ceramics is improved, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com