A double-sided finishing fixture for large thin-walled flanges and flange processing technology

A flange and thin-walled technology, applied in the field of double-sided finishing fixtures, can solve the problem of out-of-tolerance accuracy indicators such as roundness, concentricity, flatness, parallelism, flange clamping and hoisting deformation, flatness and parallelism In order to improve the processing accuracy, overcome the deformation and processing errors, and achieve good concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

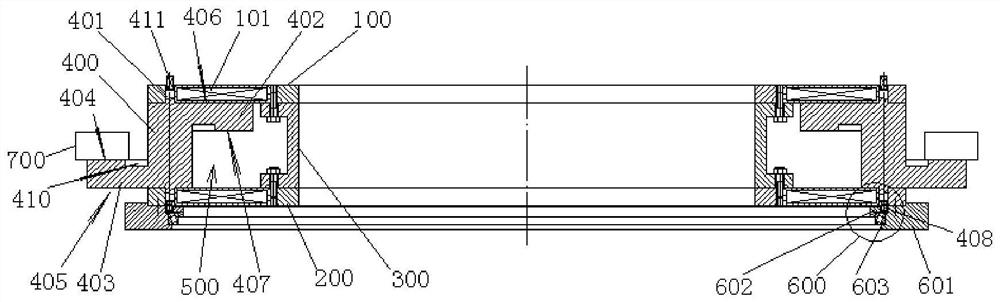

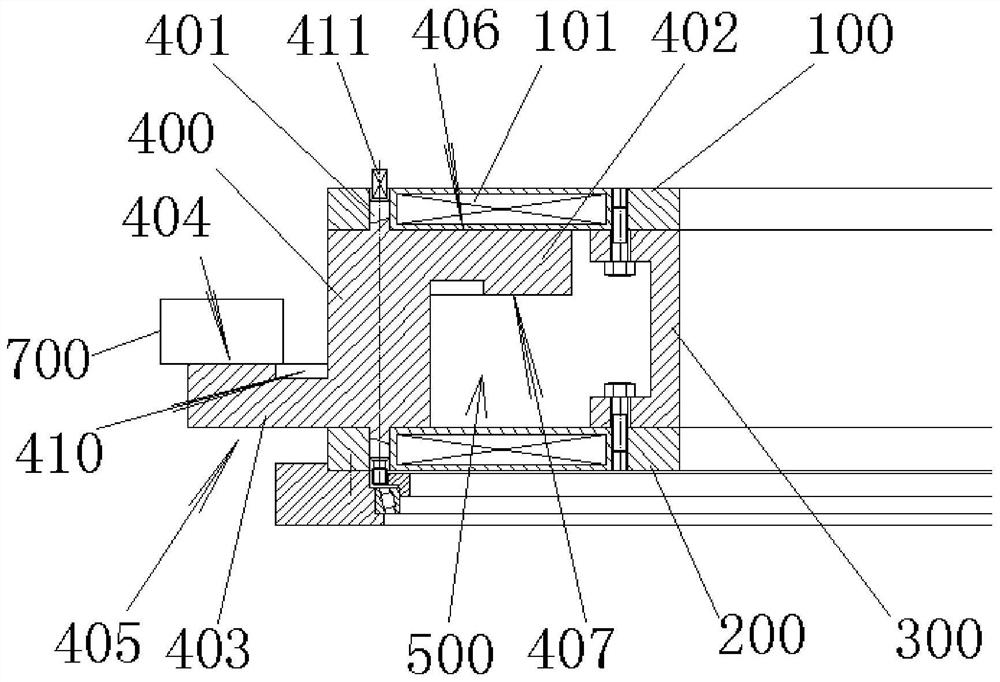

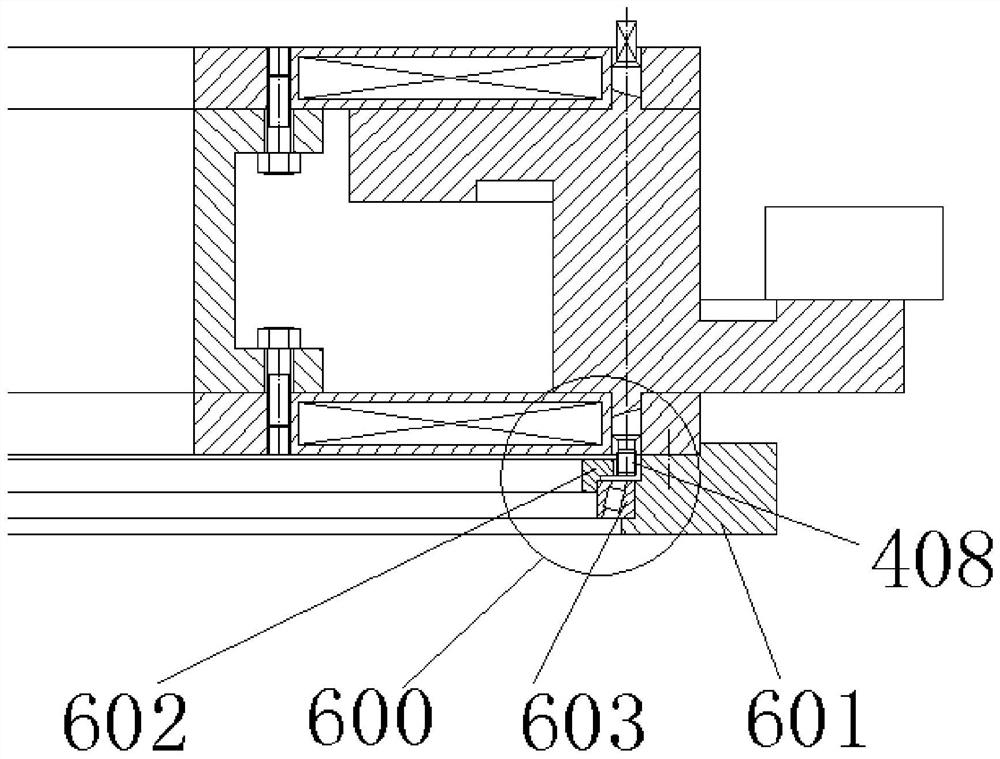

[0048] Such as Figures 1 to 6 Shown is an embodiment of a double-sided finishing fixture for a large thin-walled flange, including an upper permanent disk 100, a lower permanent disk 200, a non-magnetically conductive intermediate connecting disk 300, and several rotating positioning claws made of magnetically conductive materials 400, the upper permanent magnetic disk 100 and the lower permanent magnetic disk 200 are fixed into one body through the intermediate connecting disk 300, and an annular groove is formed between the lower end surface of the upper permanent magnetic disk, the upper end surface of the lower permanent magnetic disk, and the outer circle of the intermediate connecting disk space 500; the rotary positioning claw 400 is provided with a rotating shaft 401, an upper positioning claw 402, and a lower positioning claw 403, and the rotary positioning claw 400 is installed on the space 500 of the annular groove through the rotating shaft 401 Between the permane...

Embodiment 2

[0059] The processing technology of the double-sided finishing fixture of a large thin-walled flange of this embodiment includes the following steps:

[0060] Step 1, installing the double-sided finishing fixture of a large thin-walled flange of the embodiment on the vertical lathe workbench;

[0061] Step 2. Position the lower end face of the flange on the lower positioning claw 403, and adjust the center position of the flange;

[0062] Step 3, the magnetic force of the lower permanent magnetic disk 200 is turned on, and the magnetic force of the upper permanent magnetic disk 100 is turned off;

[0063] Step 4, finish turning the outer circle, inner hole and upper end surface of the flange;

[0064] Step 5. Place 3 temporary magnetic L-shaped stoppers on the workbench. The temporary magnetic L-shaped stoppers are distributed along the outer circle of the flange, and the temporary magnetic L-shaped stoppers are against the outer circle and lower end surface of the flange;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com