3D printing system applicable to high-viscosity liquid chemical mixing formation

A hybrid molding and 3D printing technology, applied in the field of 3D printing, can solve the problems of expensive 3D printers, low heat dissipation efficiency, and inability to dissipate heat, so as to improve the appearance quality and internal structure quality, improve mixing efficiency and mixing uniformity, The effect of improving heat dissipation efficiency and heat dissipation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

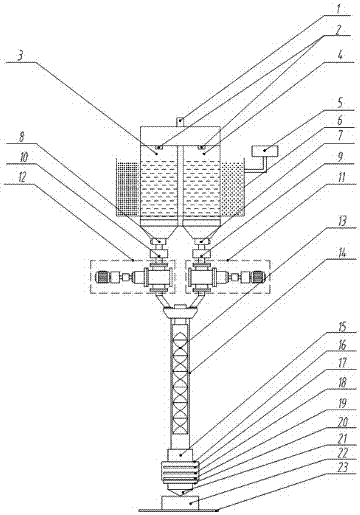

[0030] Such as figure 1 , figure 2 As shown, a 3D printing system suitable for high-viscosity liquid chemical hybrid molding, including: storage tank I3, storage tank II4, the upper side of the storage tank I3, storage tank II4 is equipped with an ultrasonic generating device 2 The upper ends of the storage tank I3 and II4 are provided with an exhaust port 1, the lower side of the storage tank I3 is provided with a high-viscosity liquid feed pump I12, and the lower side of the storage tank II4 is provided with a high-viscosity liquid supply pump. Material pump II11, the high-viscosity liquid feed pump I12, and the lower end of the high-viscosity liquid feed pump II11 are connected to the mixing barrel 14 through a three-way pipe. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com