Production technology of anti-bacterial textile fabric

A technology for textile fabrics and production processes, applied in textile and papermaking, knitting, weft knitting and other directions, can solve the problems of complex production process, high production cost, unsatisfactory antibacterial performance, etc., and achieve simple process method, low production cost, The effect of good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

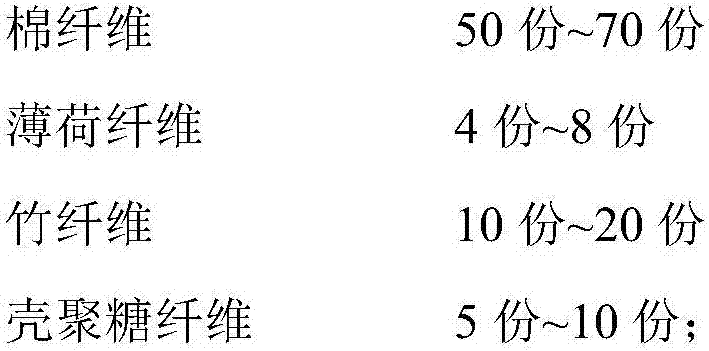

[0031] A production process of an antibacterial textile fabric, the antibacterial textile fabric is knitted from yarn, and the yarn is made of the following raw materials in parts by weight:

[0032]

[0033] The production technology of this antibacterial textile fabric, it comprises the following steps:

[0034] Step 1, fabric weaving: use cotton fiber, mint fiber, bamboo fiber and chitosan fiber to spin and weave to obtain the woven fabric;

[0035] Step 2, washing: washing the fabric obtained in step 1;

[0036] Step 3, fabric dyeing: dyeing the fabric washed in step 2;

[0037] Step 4, antibacterial treatment: put the fabric dyed in step 3 into the antibacterial solution for immersion; in this embodiment, the time of immersion is 450min;

[0038] Step 5, shaping: shaping the fabric after the antibacterial treatment in step 4 to obtain an antibacterial textile fabric;

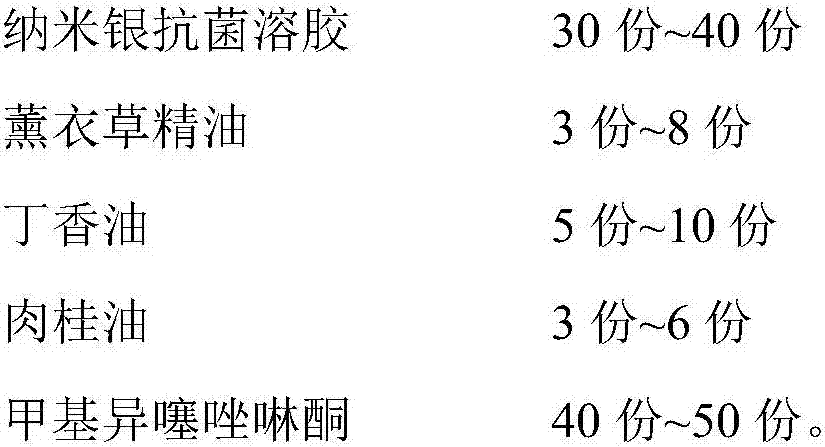

[0039] Wherein, the antibacterial liquid in step 4 is made up of the component of following parts ...

Embodiment 2

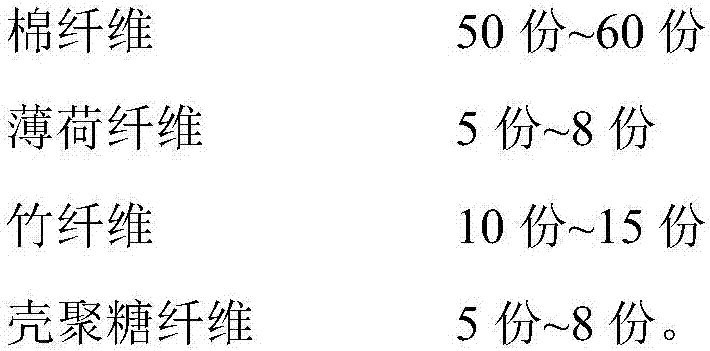

[0042] A production process of an antibacterial textile fabric, the antibacterial textile fabric is knitted from yarn, and the yarn is made of the following raw materials in parts by weight:

[0043]

[0044] The production technology of this antibacterial textile fabric, it comprises the following steps:

[0045] Step 1, fabric weaving: use cotton fiber, mint fiber, bamboo fiber and chitosan fiber to spin and weave to obtain the woven fabric;

[0046] Step 2, washing: washing the fabric obtained in step 1;

[0047] Step 3, fabric dyeing: dyeing the fabric washed in step 2;

[0048] Step 4, antibacterial treatment: put the fabric dyed in step 3 into the antibacterial solution for immersion; in this embodiment, the time of immersion is 30min;

[0049] Step 5, shaping: shaping the fabric after the antibacterial treatment in step 4 to obtain an antibacterial textile fabric;

[0050] Wherein, the antibacterial liquid in step 4 is made up of the component of following parts b...

Embodiment 3

[0054] A production process of an antibacterial textile fabric, the antibacterial textile fabric is knitted from yarn, and the yarn is made of the following raw materials in parts by weight:

[0055]

[0056] The production technology of this antibacterial textile fabric, it comprises the following steps:

[0057] Step 1, fabric weaving: use cotton fiber, mint fiber, bamboo fiber and chitosan fiber to spin and weave to obtain the woven fabric;

[0058] Step 2, washing: washing the fabric obtained in step 1;

[0059] Step 3, fabric dyeing: dyeing the fabric washed in step 2;

[0060] Step 4, antibacterial treatment: put the fabric dyed in step 3 into the antibacterial solution for immersion; in this embodiment, the time of immersion is 60min;

[0061] Step 5, shaping: drying and shaping the fabric after the antibacterial treatment in step 4 to obtain an antibacterial textile fabric;

[0062] Wherein, the antibacterial liquid in step 4 is made up of the component of follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com