Tire type metro replaced laying machine and span changing method thereof

A tire-type, paving machine technology, applied in the direction of laying tracks, traveling mechanisms, lifting equipment braking devices, etc., can solve the problems of damage to the strength of curved surfaces and planes, increase the cost of manpower and material resources, and affect the construction progress, etc. The effect of meeting the clearance requirements, reducing the cost and improving the safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing.

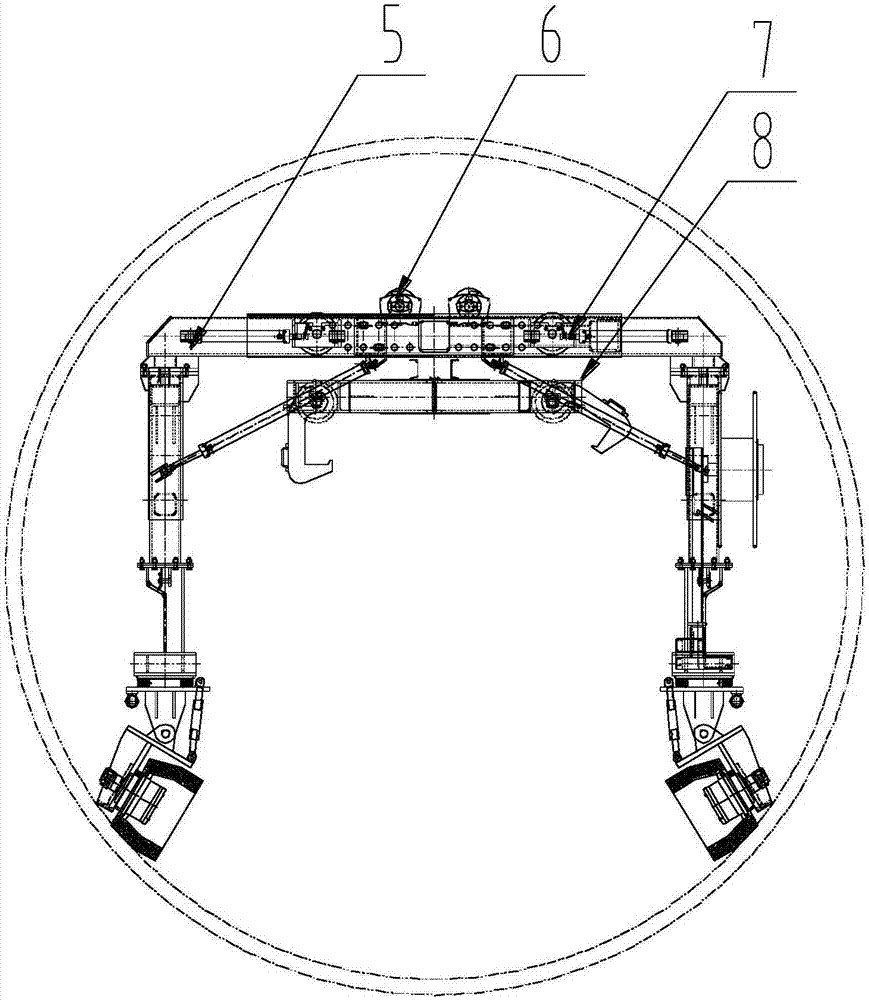

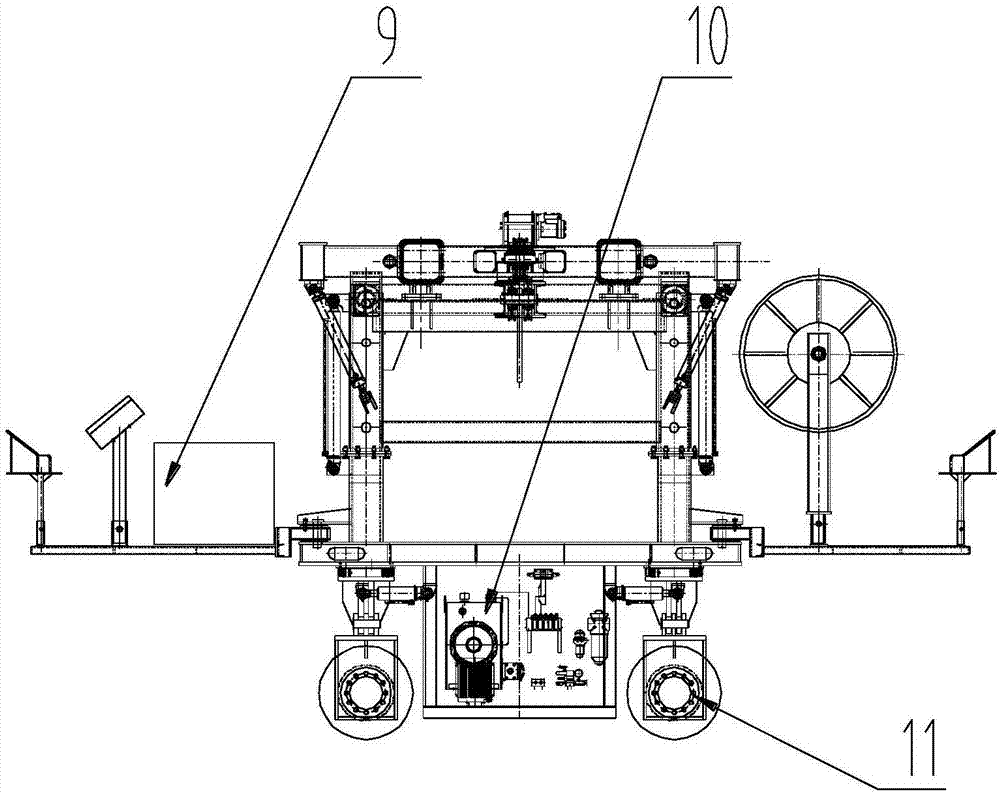

[0045] Such as Figure 1-2 As shown, the present embodiment provides a tire-type subway pavement machine, which includes a gantry structure 5, a lifting structure 6, a variable span structure 7, a multifunctional spreader 8, an electrical system / 9, a hydraulic system 10, the above-mentioned Walking device 11, the gantry structure includes a main beam and column structures installed on both sides of the main beam, the column structure is at least a secondary telescopic structure, the main beam is at least a secondary telescopic structure, the lifting The structure is installed on the main beam, and the outrigger structure is also configured on the column structure.

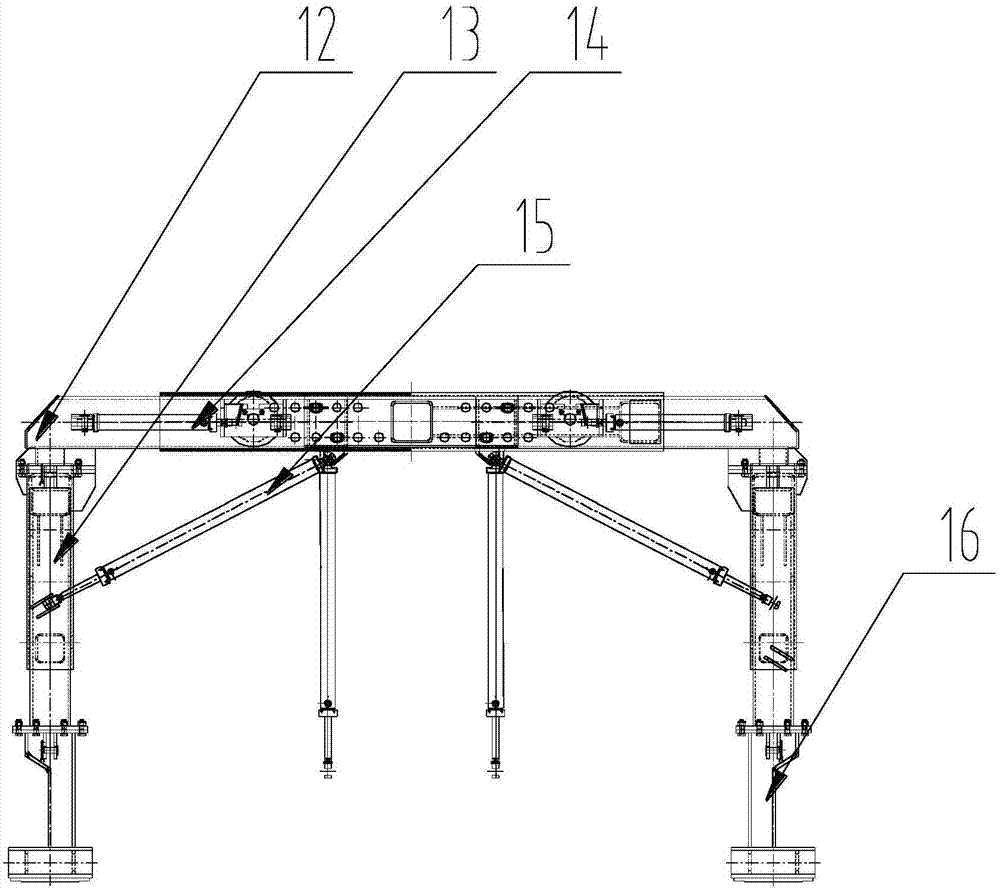

[0046] Such as Figure 3-5 As shown, the gantry structure is mainly composed of one set of main beam 12, two sets of column structures 13, four traversing oil cylinders 14, two sets of turning legs 16, and fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com