Construction Technology of Hydraulic Synchronous Lifting and Installation of Steel Truss Corridor

A technology of hydraulic synchronous lifting and construction technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of affecting the efficiency of installation, incapable of cross operation, taking a long time, etc., to achieve high construction efficiency, guarantee The effect of high installation period and construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

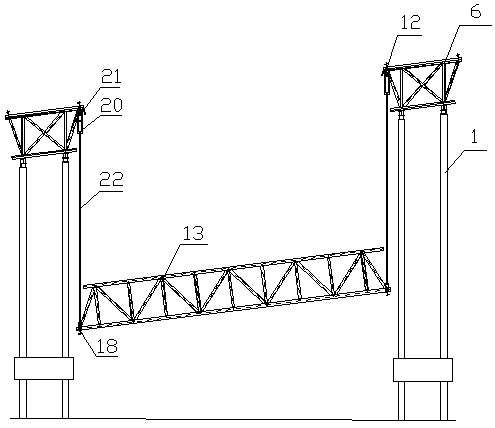

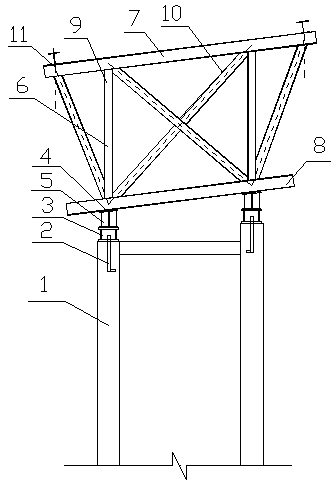

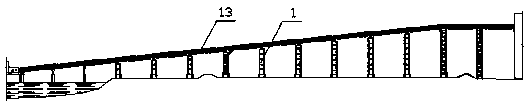

[0046] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0047] The hydraulic synchronous lifting installation construction technology of the steel truss corridor according to the present invention comprises the following steps:

[0048] (1) Install the embedded part 2 on the top of the column 1;

[0049] (2) Laying out the top of the column;

[0050] (3) Install the hinge support: hoist the hinge support 3 to the top of the column 1, align it with the installation axis, check the elevation again after positioning, and install the hinge support after confirming that it meets the requirements. The support 3 is reliably welded to the embedded part 2 on the top of the column;

[0051] (4) Positioning control of the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com