Under-shaft fracture data wireless transmission device

A wireless transmission and data technology, applied in wellbore/well components, production fluid, measurement, etc., can solve problems such as large fluctuations in surface pressure and difficulty in obtaining pressure data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

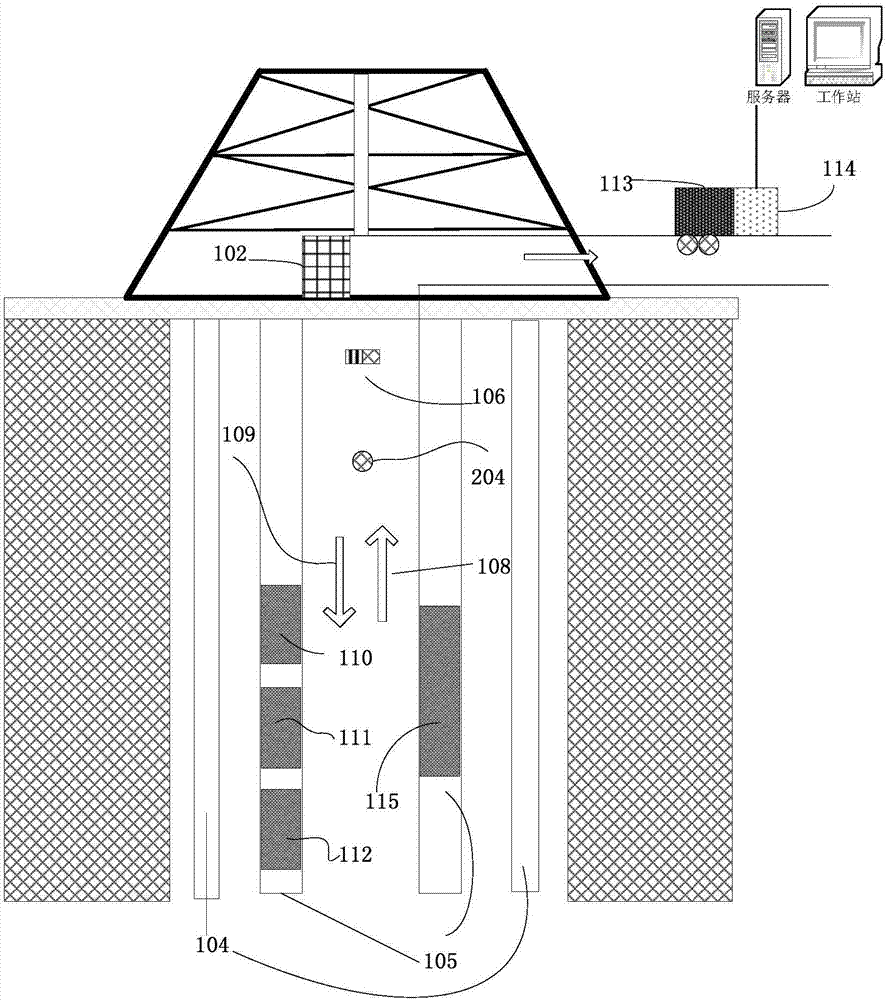

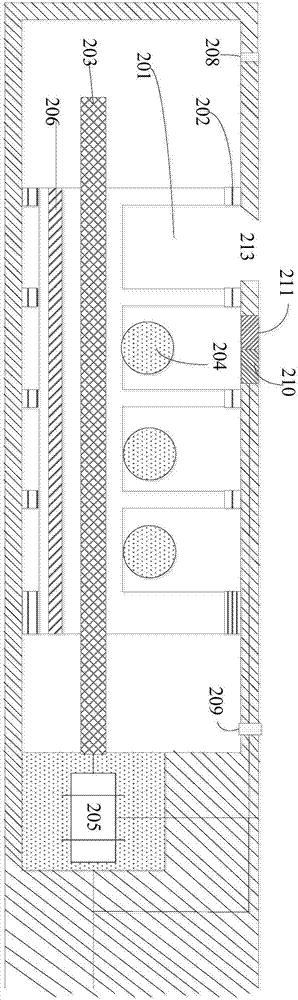

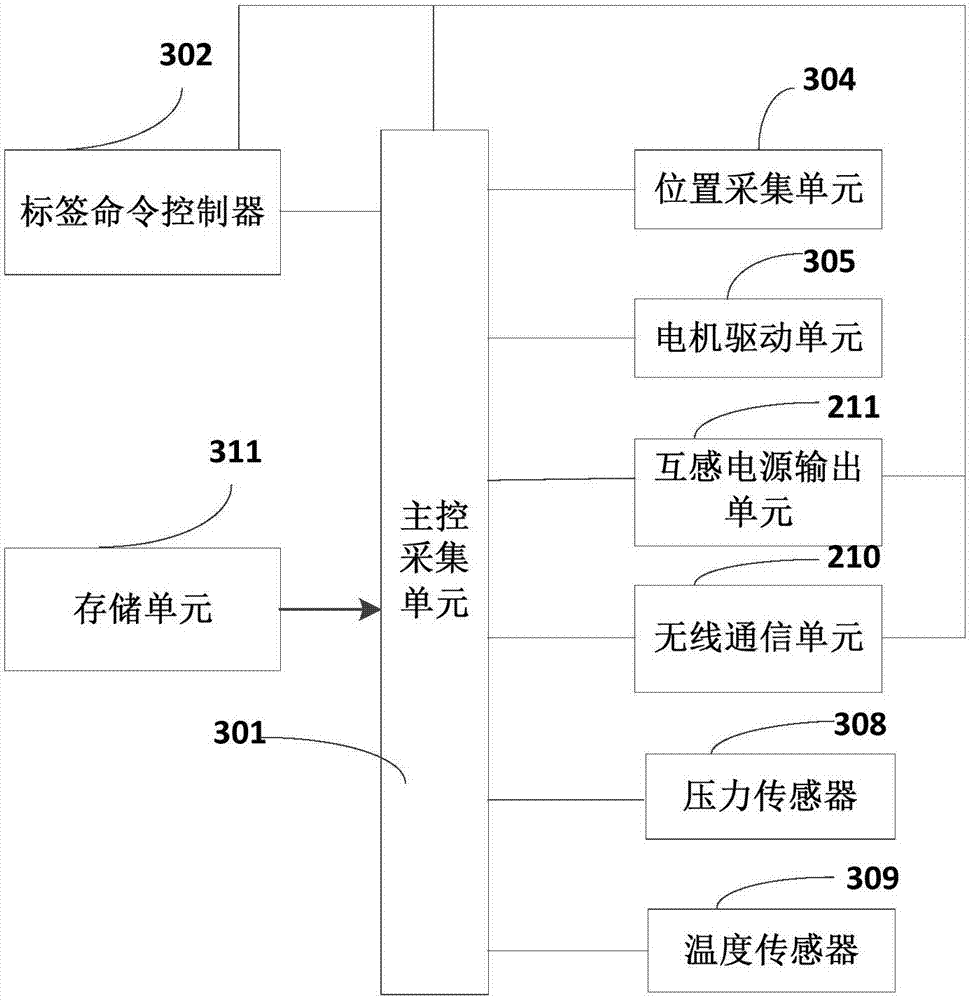

[0026] like Figure 1~3 As shown, a wireless transmission device for downhole fracturing data includes a command tag 106, a ground information ball data reading device 114, a label delivery device 102 and an information ball capture device 113 installed at the wellhead, and a motor installed on the coiled tubing 105. Control and pitching short section 110, main control communication short section 111, data acquisition short section 112 and battery pack 115;

[0027] The ground information ball data reading device 114 is connected to the server and can transmit the read data to it;

[0028] The battery pack 115 is respectively connected to the electrical equipment in the motor control and pitching sub-section 110, the main control communication sub-section 111, and the data acquisition sub-section 112 to supply power;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com