Layer structure mass block and manufacturing method thereof, and acceleration sensor and manufacturing method thereof

A technology of acceleration sensor and manufacturing method, which is applied in the directions of speed/acceleration/shock measurement, acceleration measurement using inertial force, detailed information of speed/acceleration/electric shock meter, etc., can solve the problem of high temperature resistance density and poor thermal compatibility of acceleration sensor , The thermal adaptation of the overall structure is not considered, and the thermal expansion coefficient of the material is not considered, so as to achieve the effect of good thermal adaptation and good overall thermal adaptation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

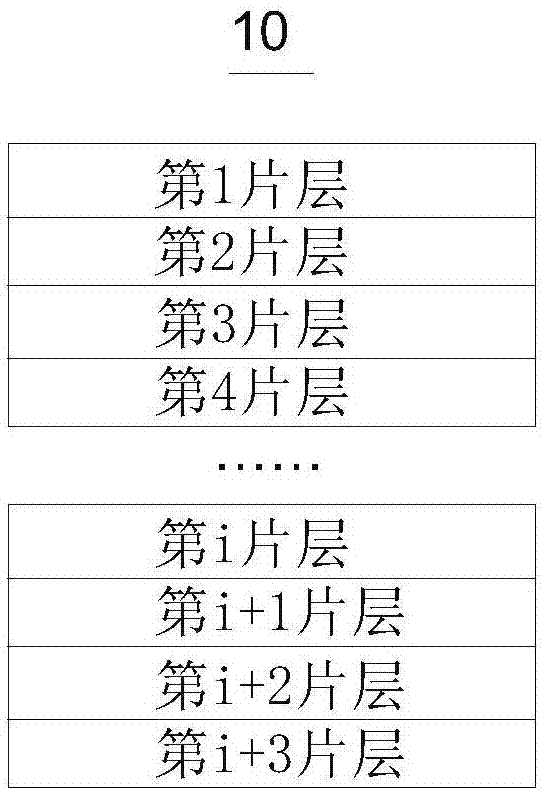

[0076] Using the above-mentioned preparation method of the layered mass 10, the comprehensive thermal expansion coefficient of the layered mass 10 is equal to the first preset coefficient of expansion, and the thickness ratio of each layer is obtained, and then the specific thickness of each layer is determined to make the total thickness Is L.

[0077] In the embodiment of the present invention, the sensitive element may include multiple, and the expansion effect of multiple linearly arranged sensitive elements should be superimposed.

[0078] Then, the layered structural mass 10 is assembled with sensitive elements, studs, etc. to obtain an acceleration sensor.

Embodiment 1

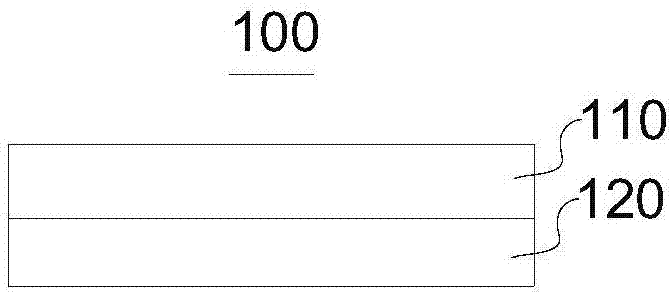

[0081] figure 2 It is a schematic structural diagram of the middle-layer structural mass 100 in Embodiment 1 of the present invention from a first perspective; image 3 It is a schematic view of the structure of the mass 100 in the second embodiment of the present invention. Please refer to figure 2 with image 3 This embodiment provides a layered mass 100 and a manufacturing method thereof, an acceleration sensor and a manufacturing method thereof.

[0082] Figure 5 It is a schematic diagram of a partial structure of the acceleration sensor 300 in Embodiment 1 of the present invention. Please refer to Figure 5 In this embodiment, the acceleration sensor 300 includes a mass 100, a stud 310, and a sensitive element 320. The stud 310 penetrates the mass 100 and the sensitive element 320 from the thickness direction, and is fastened by a nut 330. In the case where the thickness of the nut 330 is small relative to the mass 100 and the sensitive element 320, the thermal expansi...

Embodiment 2

[0091] Figure 4 It is a schematic diagram of the structure of the mass block 200 in the second embodiment of the present invention. This embodiment provides a layered structure mass 200 and a manufacturing method thereof. The manufactured layered structure mass 200 needs to meet the first predetermined expansion coefficient and density requirements in Embodiment 1.

[0092] In this embodiment, three plies are selected to make the layer structure mass 200. Specifically, the layered mass 200 includes a rectangular first layer 210, a second layer 220, and a third layer 230. The first layer 210 is gold with a density of 19.3 g / cm 3 , The thermal expansion coefficient is 14.2E-6 / K; the second layer 220 is iron, and the density is 7.8g / cm 3 , The thermal expansion coefficient is 12.2E-6 / K; the third layer 230 is manganese, and the density is 7.4g / cm 3 , The thermal expansion coefficient is 23E-6 / K. The three layers are connected by bonding.

[0093] First preset the thickness ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com