Novel symmetrical electrode material, fuel cell and preparation method thereof

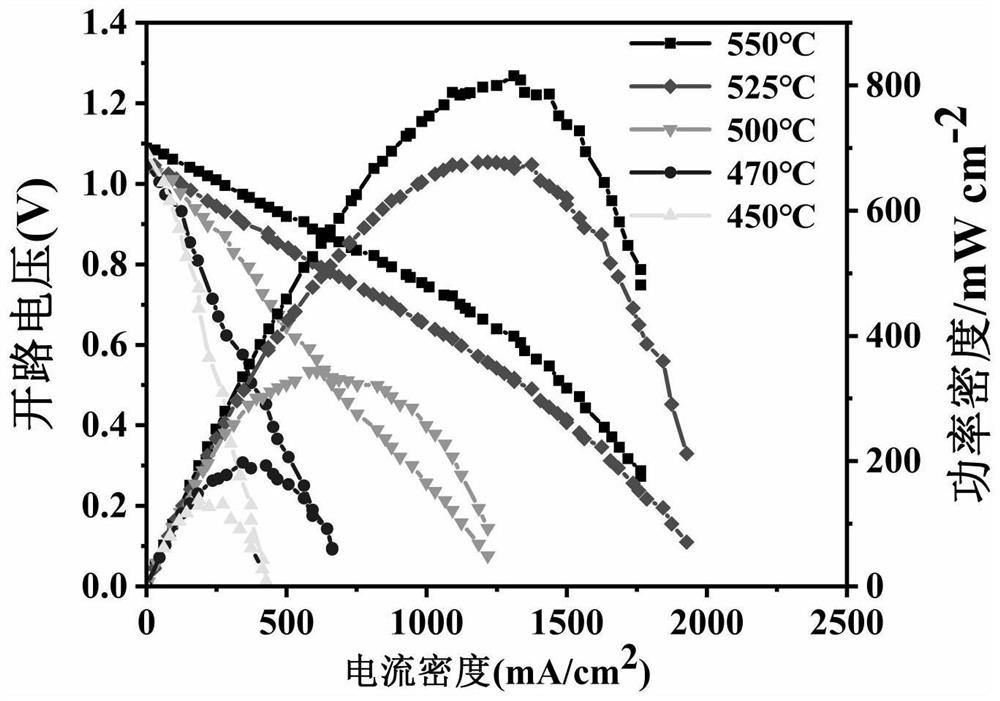

A symmetrical electrode and fuel cell technology, applied in fuel cells, battery electrodes, chemical instruments and methods, etc., can solve problems such as unfavorable commercialization of SOFC, difficulty in obtaining stability of symmetrical cells, etc., to expand the three-phase reaction interface, manufacture Simple method, excellent mechanical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] According to the technical solution of the present invention, a specific method for preparing a novel symmetric electrode material includes the following steps:

[0048] (1) The CoSO 4 ·7H 2 O and MnSO 4 ·4H 2 O is mixed and dissolved in deionized water according to the stoichiometric ratio, and Na with a concentration of 1.5 to 2.5 mol / L is added to the mixed solution. 2 CO 3 The solution is 300-400ml, and an ammonia solution with a concentration of 1.5-2.5mol / L is added to adjust the pH to 7-8, and then heated in a water bath at 35-45°C to obtain a precipitate;

[0049] (2) after solid-liquid separation and washing of the obtained precipitate, drying at 110-130° C. for 10-14 hours to obtain an intermediate product;

[0050] (3) heating the obtained intermediate product at 350-450° C. for 9-11 h to obtain a decomposed product;

[0051] (4) The obtained decomposed product was mixed with Ni(NO 3 ) 2 ·6H 2 O and LiNO 3 The mixture is uniformly mixed according to...

Embodiment 1

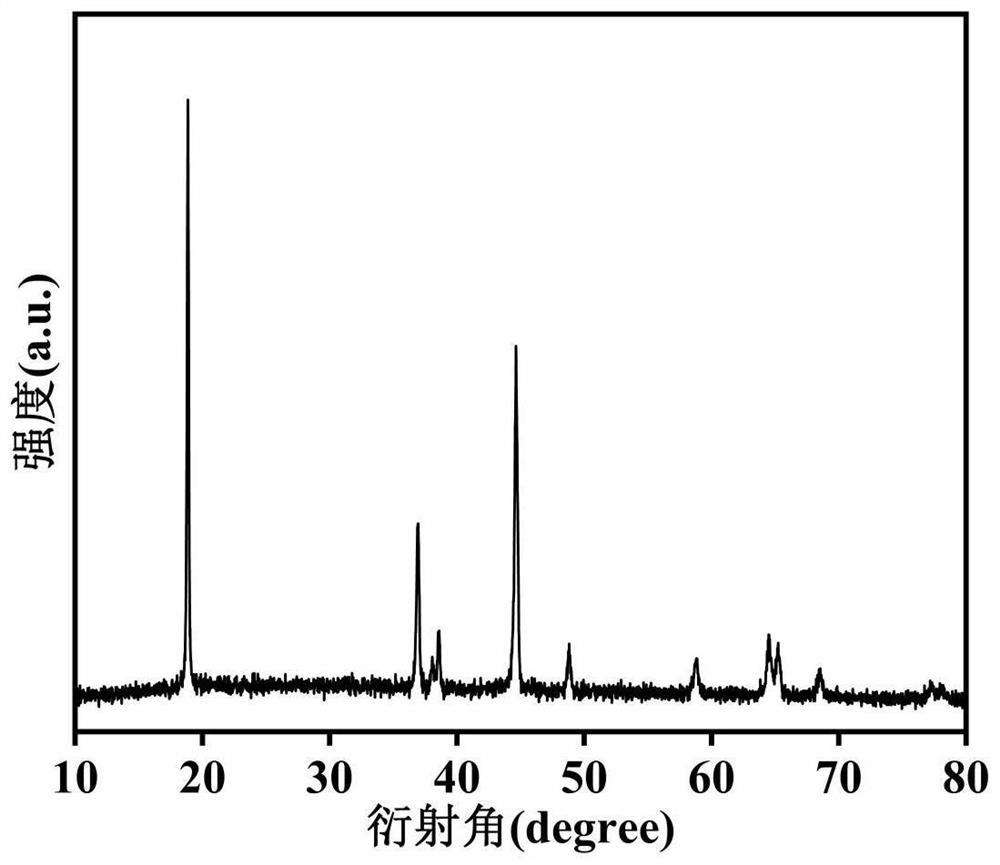

[0063] ABO is prepared by the following procedure 2 Type oxide LNCM:

[0064] (1) CoSO with a stoichiometric ratio of 1:1 4 ·7H 2 O and MnSO 4 ·4H 2 O powder was mixed and dissolved in deionized water to form a mixed solution with a solute concentration of 2 mol / L, and then 2 mol / L Na 2 CO 3 The solution was uniformly added to the obtained sulfate mixed solution to form a purple precipitate. Weigh 5 g of ammonia water with a concentration of 20%, add 343 ml of deionized water, and stir evenly to form a 0.24 mol / L ammonia solution. Slowly drop the ammonia solution. Add into the mixed solution to adjust the pH, control the pH of the solution at 7.5, and place the mixed solution on a stirrer with a temperature of 40°C and a rotation speed of 800r / min for 4h;

[0065] (2) filter the precipitate obtained in step (1), and rinse twice with deionized water to remove residual Na 2 CO 3 ;

[0066] (3) placing the obtained precipitate in a blast drying oven with a temperature of...

Embodiment 2

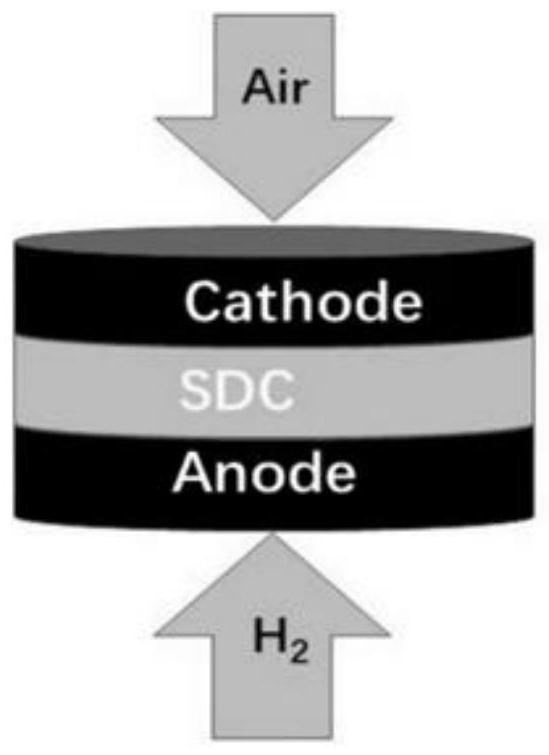

[0071] Symmetrical electrodes are prepared by the following procedure:

[0072] According to the ratio of mass to volume of 3:1, for example, 3 g of LNCM powder obtained in Example 1 corresponds to 1 ml of terpineol. The LNCM powder and terpineol were mixed uniformly in a grinding bowl and ground for 15 minutes to form a uniform slurry. The obtained slurry was evenly spread on nickel foam with a thickness of 2 mm, and then placed in a blast drying oven with a temperature of 120 °C for 30 min to prepare a Ni-LNCM electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com