Lens driving device, camera module, and manufacturing method of lens driving device

A technology of a lens drive device and a manufacturing method, which is applied in the direction of electromechanical devices, manufacturing of motor generators, installation, etc., can solve the problem of difficulty in ensuring the joint strength between the end of the coil and the leaf spring, hindering the thinning of the thickness dimension, and the inability to increase the number of solder joints. Material volume and other issues, to achieve the effect of reducing the number of turns, reducing the height dimension, and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

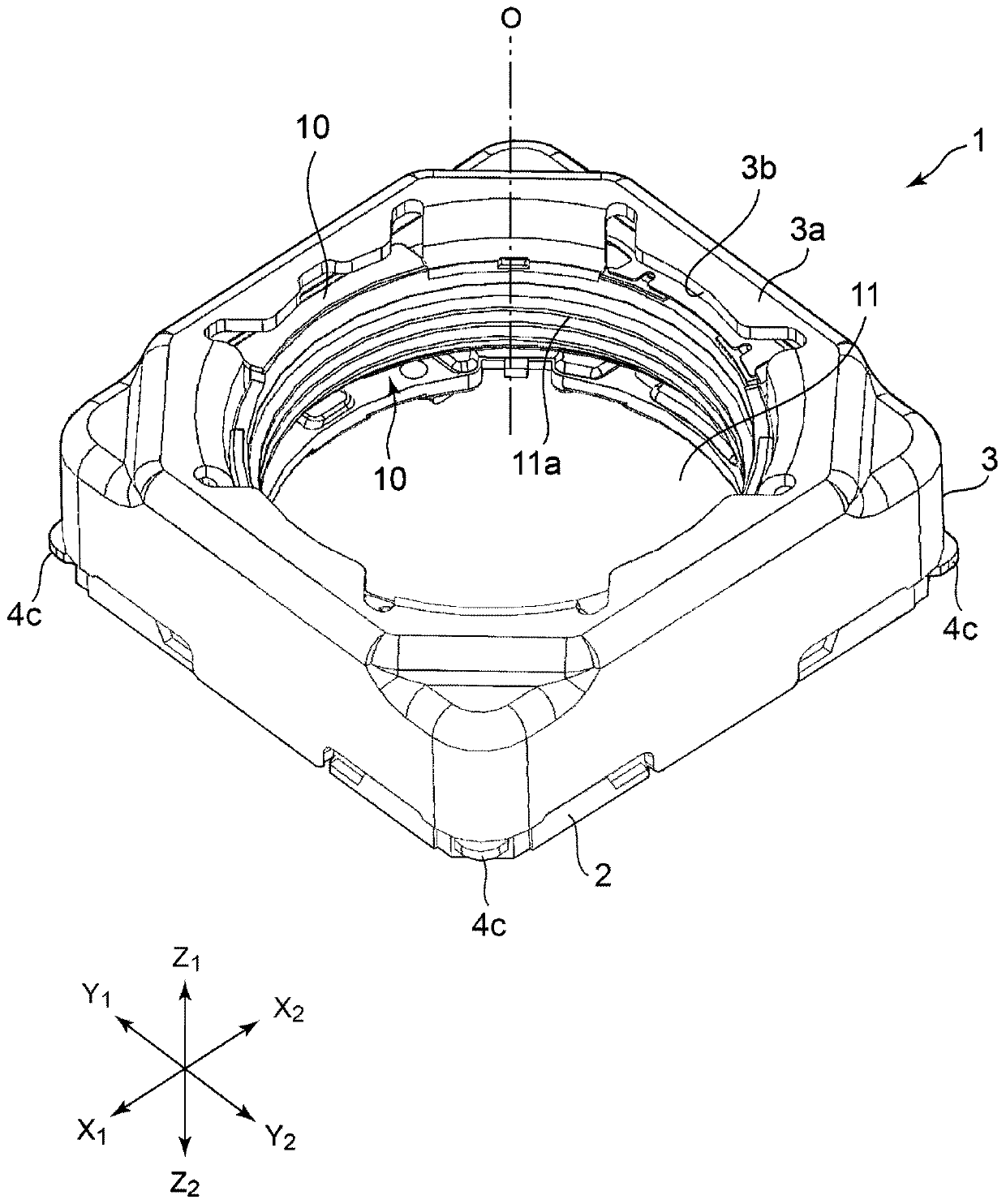

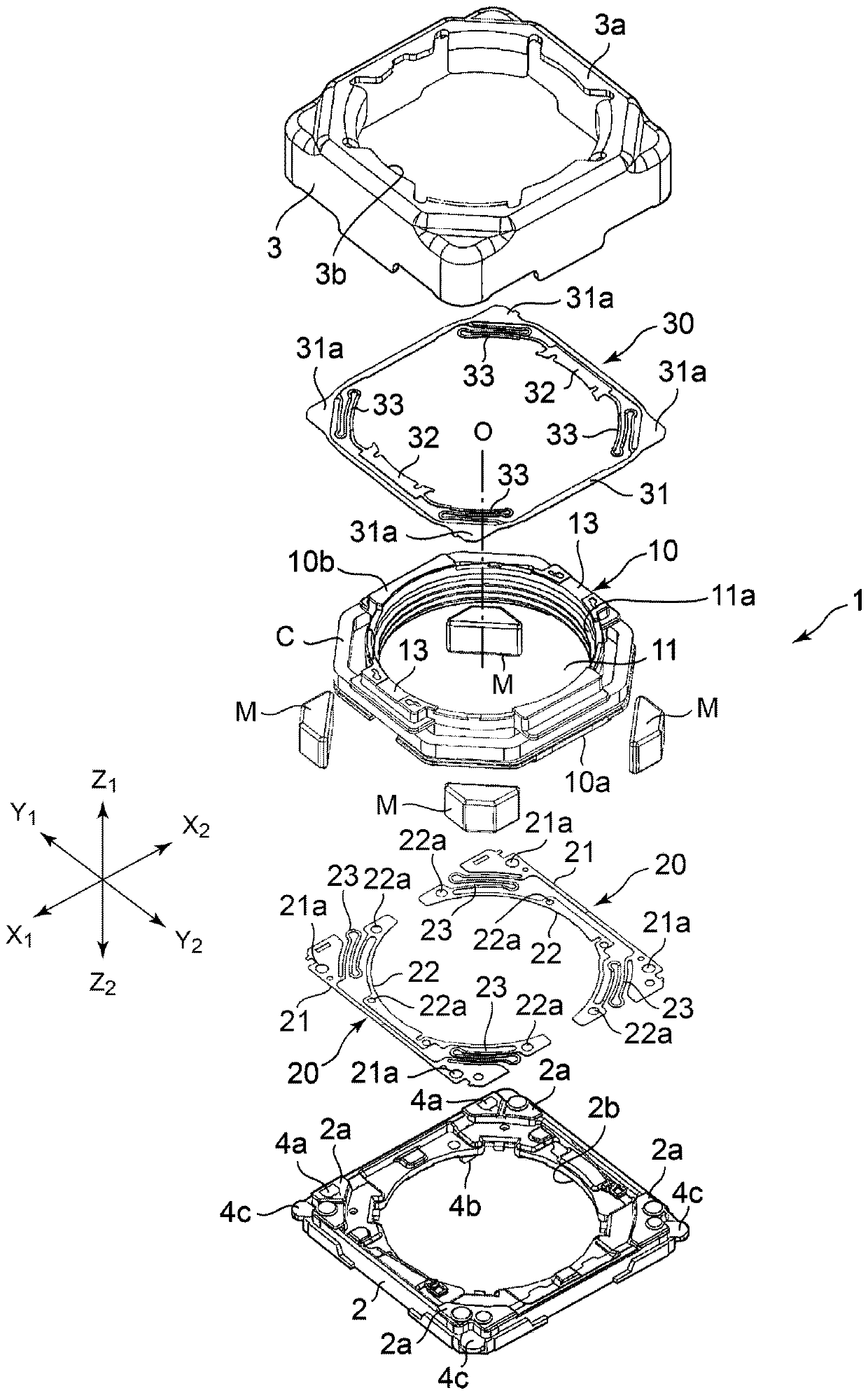

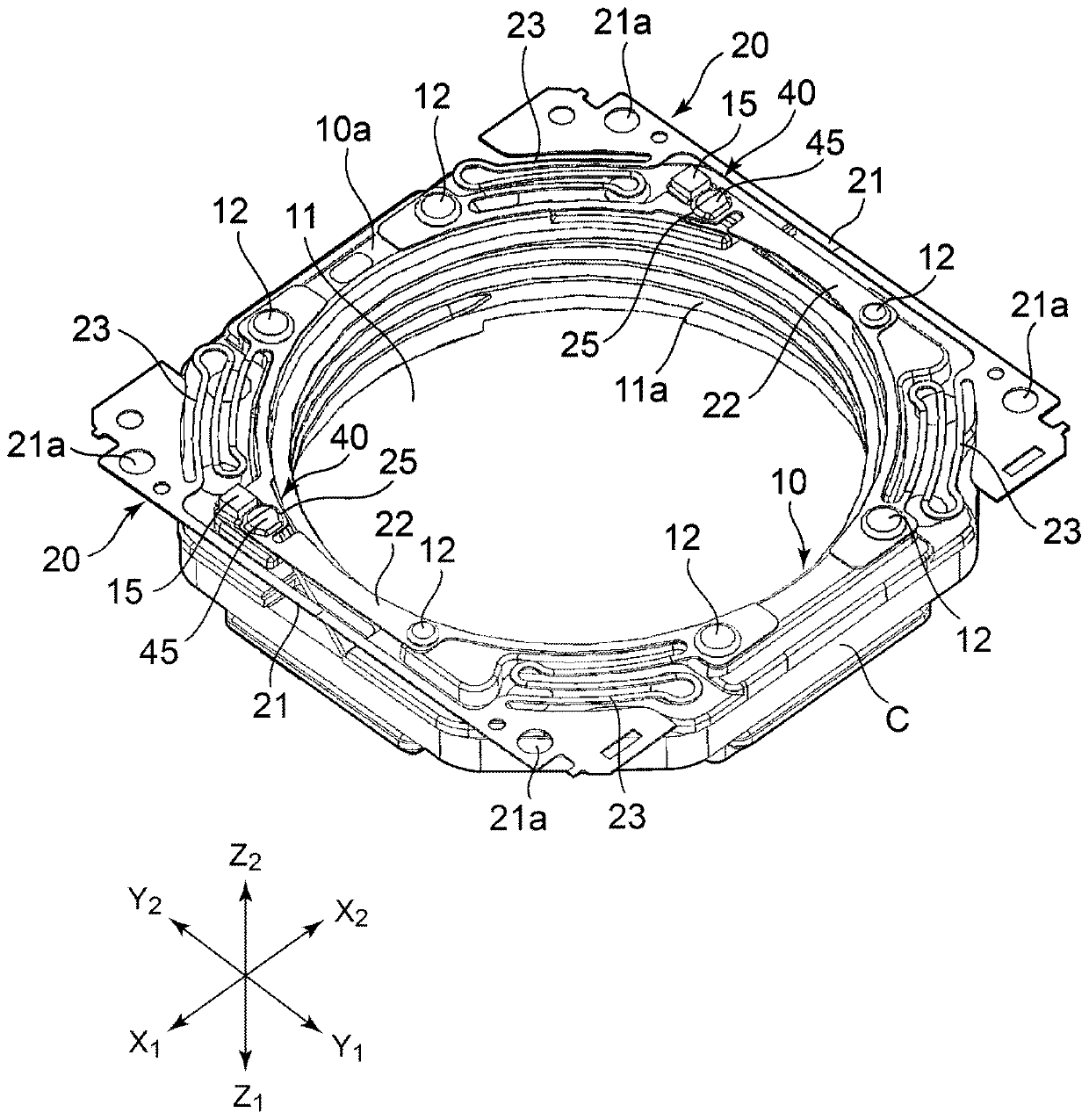

[0067] exist figure 1 and figure 2 The overall structure of the lens driving device 1 according to the embodiment of the present invention is shown in .

[0068] The lens driving device 1 has a moving member 10 . The moving member 10 is a cylindrical lens holding member. A lens body (lens barrel or lens barrel) is installed in the center hole 11 of the moving member 10 . The lens body includes a lens group composed of one lens or a plurality of lenses, and a lens holder holding the lens or the lens group. A female thread portion 11 a is formed in the center hole 11 , and a male thread portion is formed on the outer peripheral surface of the lens holder. By screwing the male thread portion and the female thread portion 11 a together, the lens body is attached and mounted on the moving member 10 . It should be noted that the lens body may also be fixed to the moving member 10 by an adhesive.

[0069] figure 1 and figure 2 The Z1-Z2 direction in is the up-down direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com