MECHATROLINK-II bus type drive control system

A drive control and drive controller technology, applied in the fields of mechanical engineering and electronic engineering, can solve the problems of slow communication speed, difficulty in expanding the number of controllable motor axes, poor accuracy, etc., and achieve fast transmission speed, load-carrying and anti-interference. The effect of strong ability and high-speed data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

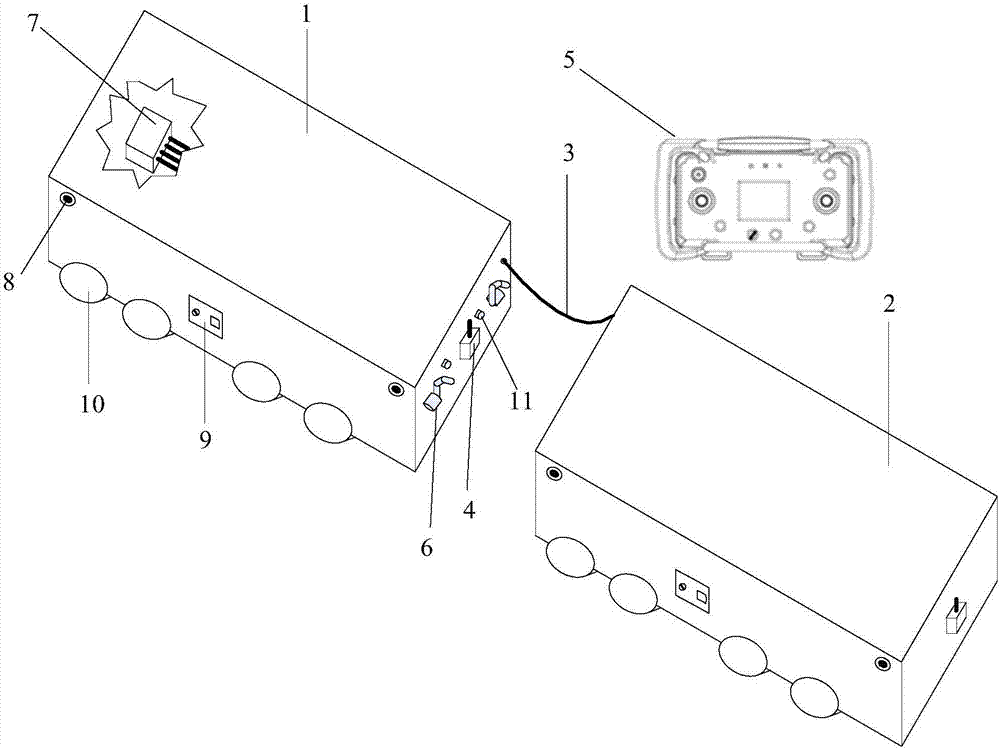

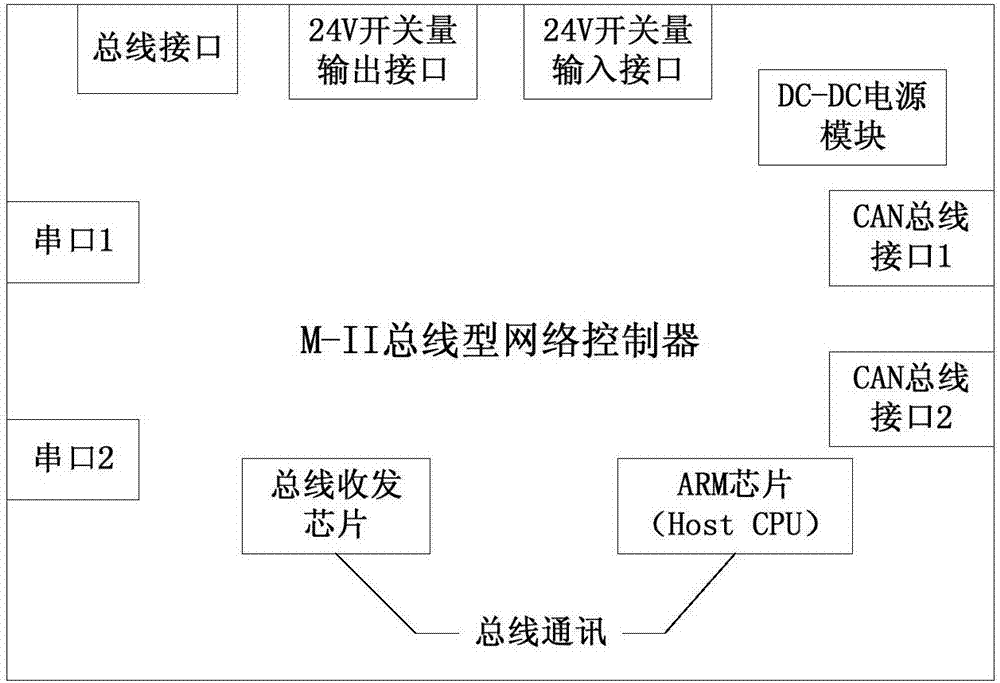

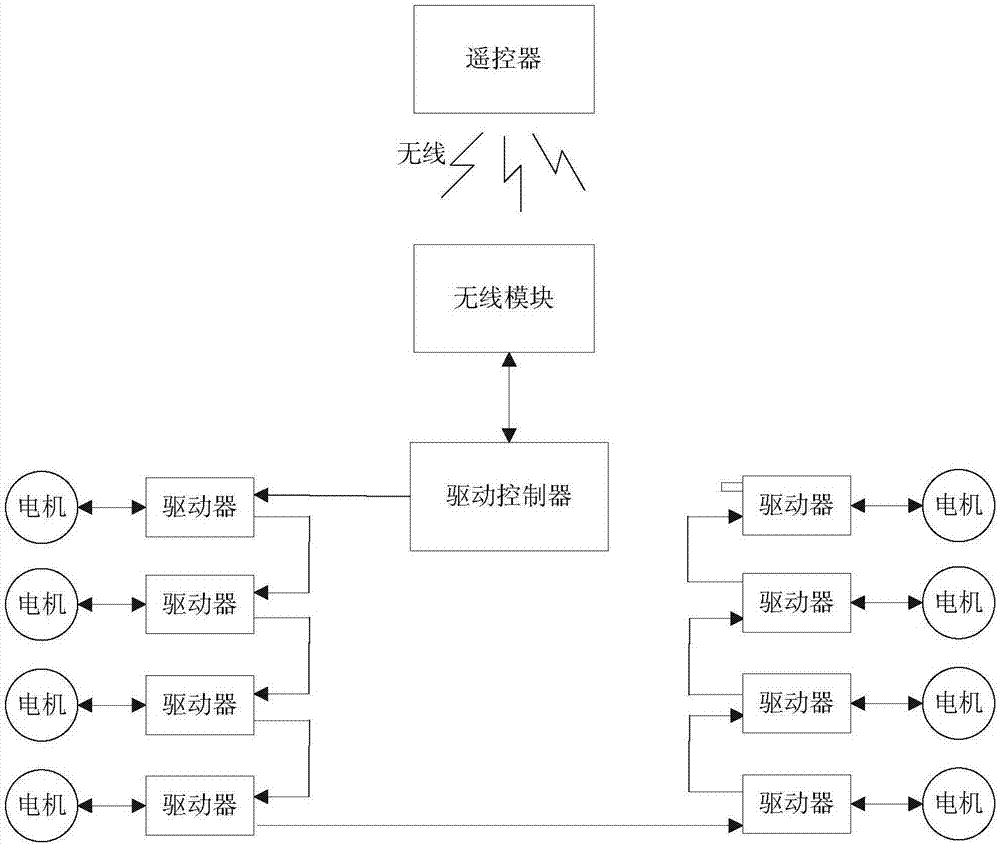

[0033] The present invention proposes a MECHATROLINK‐II bus-type drive control system, which sends remote control instructions to the wireless module of the omnidirectional mobile platform through a handheld device and receives and displays platform status information and alarm information. The drive controller analyzes the remote control instruction information obtained by the wireless communication module, and resolves the speed information and angle information in the remote control instruction of the handheld device into the speed and direction of each motor in the omnidirectional mobile platform module and the splicing and locking execution module. MECHATROLINK ‐II bus interface sends data to each motor driver, collects the status and alarm information of each motor driver at the same time, and sends it back to the handheld through the wireless communication module, which solves the problem of slow communication speed, poor control accuracy, omnidirectional The problem of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com