Gear alignment jig for auxiliary shaft assembly

A technology of hot-fitting and assembly, applied in the field of mechanical processing, can solve the problems of out-of-tolerance position, assembling multiple gears, cumbersome assembly process, etc., and achieve the effect of improving processing efficiency, reducing parts waste, and reducing waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

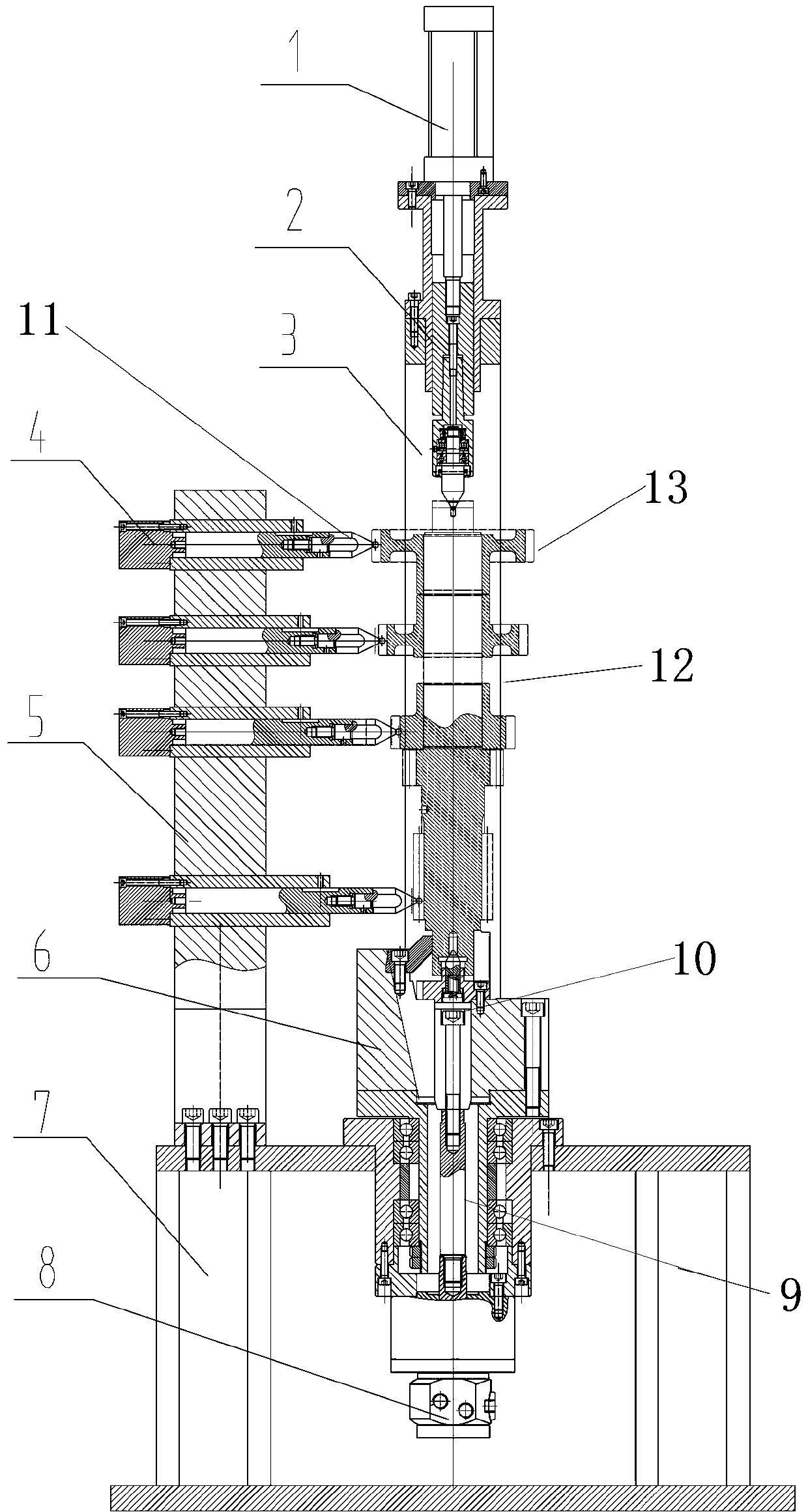

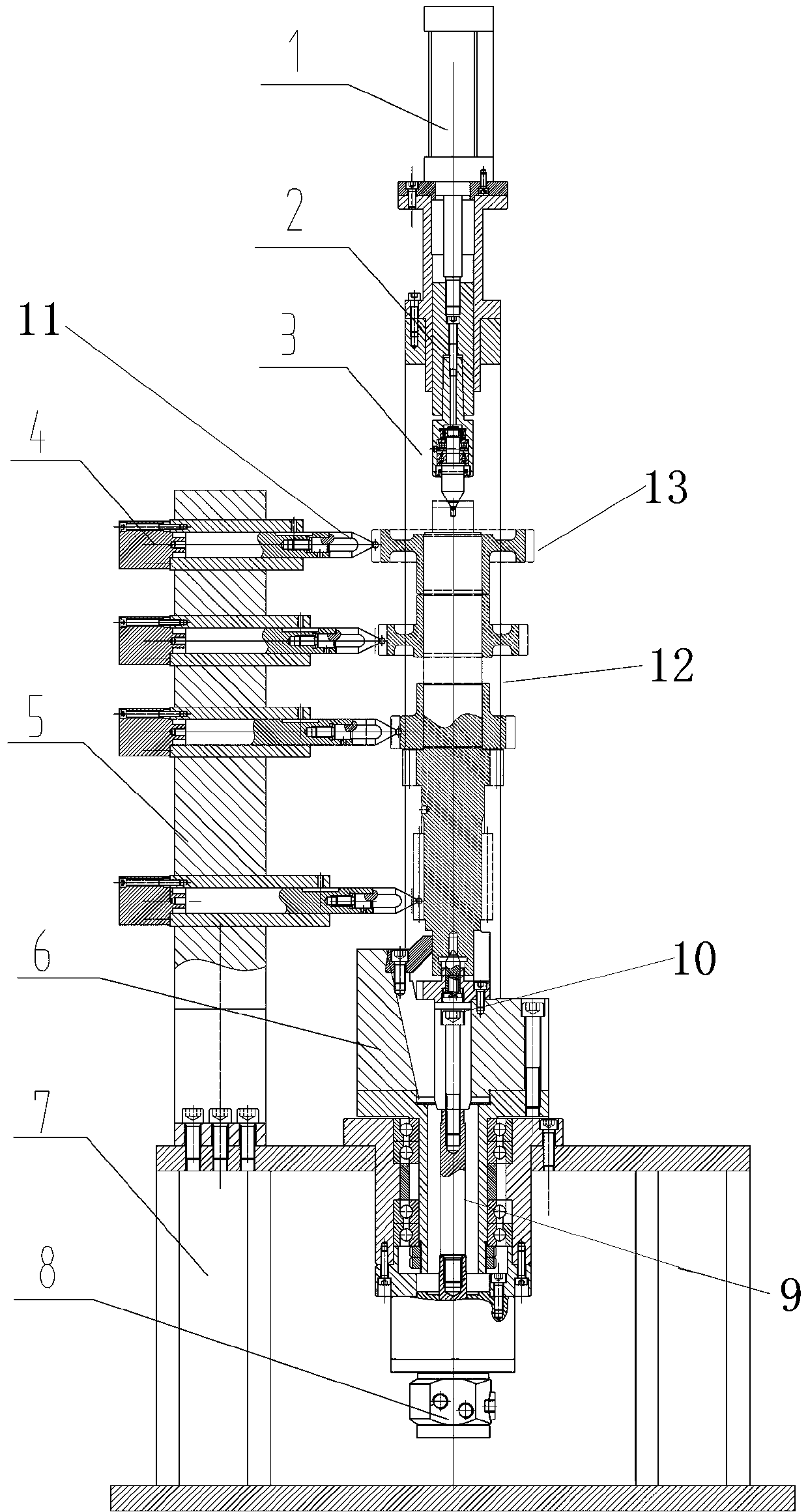

[0015] (1) The design of the heat-fitting jig:

[0016] 1) Clamping method: vertical clamping auxiliary shaft, the lower end clamps the outer circle processed after heat by hydraulic clamping (hydraulic station, rotary cylinder, power chuck), and the outer circle of the end face of the fixed axis step of the positioning plate (measuring reference plane), the upper end is pneumatically assisted to locate the center hole of the shaft;

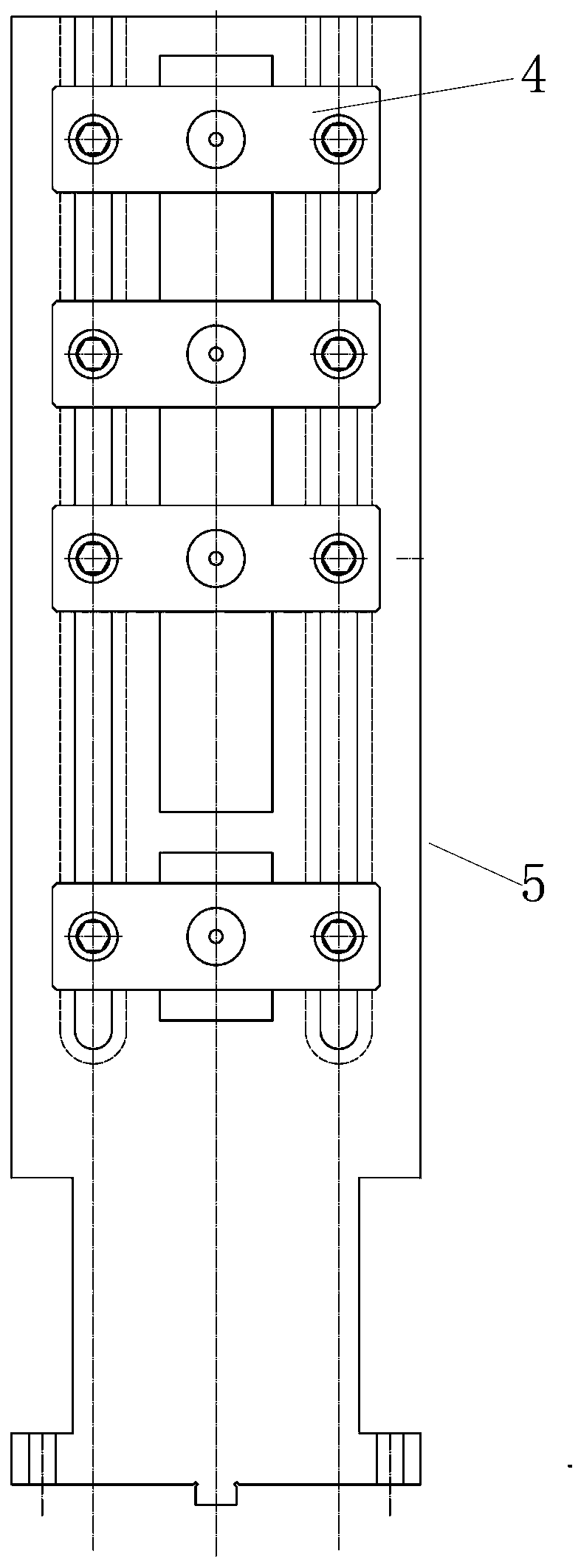

[0017] 2) Alignment method: The tooth pairing mechanism is on the left side of the workbench. Now it is equipped with 4 pneumatic ball-shaped alignment columns, 1 shaft tooth, and 3 gear teeth (the number can be increased according to product requirements), and the production is replaced. The upper and lower positions of the tooth column can be adjusted individually according to the requirements of the drawing;

[0018] 3) On-site installation and fixation of the tooling: Since the height of the top of the tooling exceeds 1.7 meters, in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com