A hdpe winding pipe production equipment

A production equipment and winding pipe technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of easy disconnection of pipes, uneven heating, low heating temperature, etc., and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

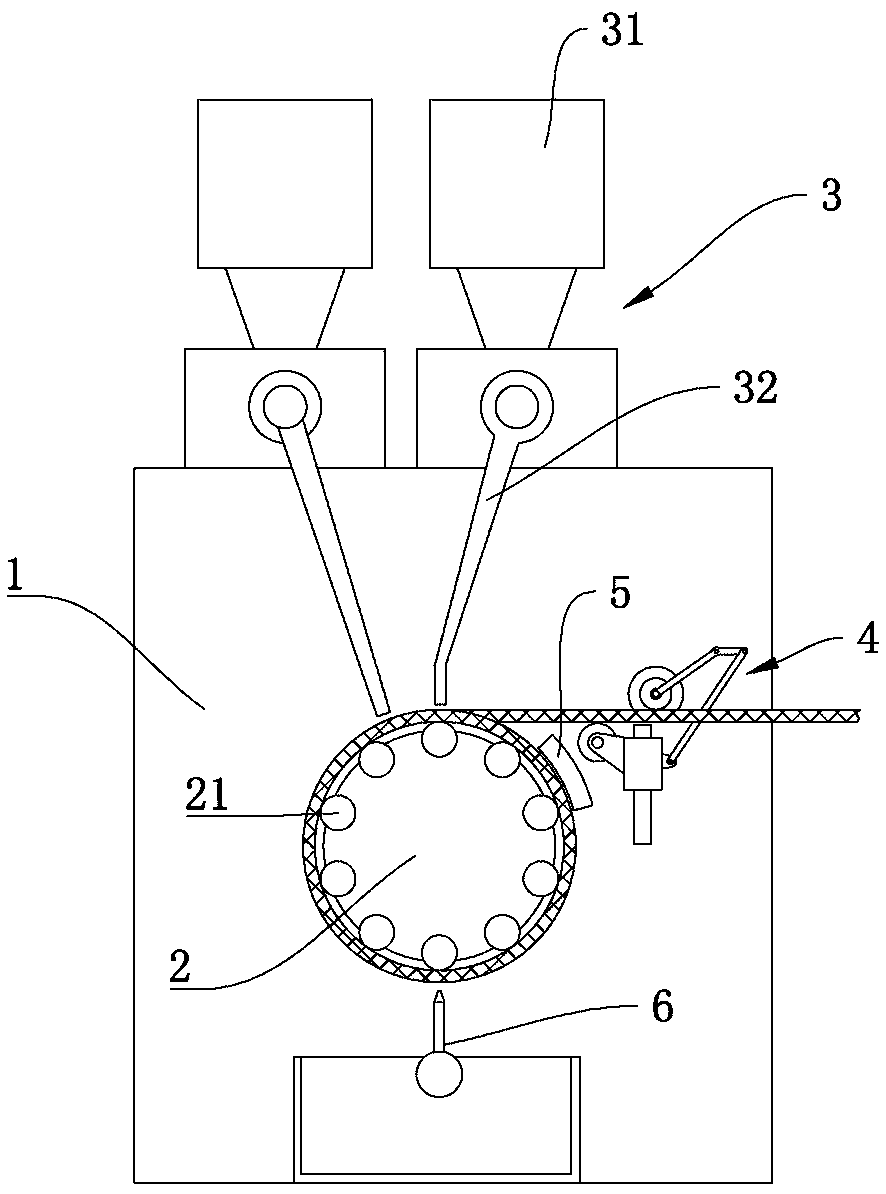

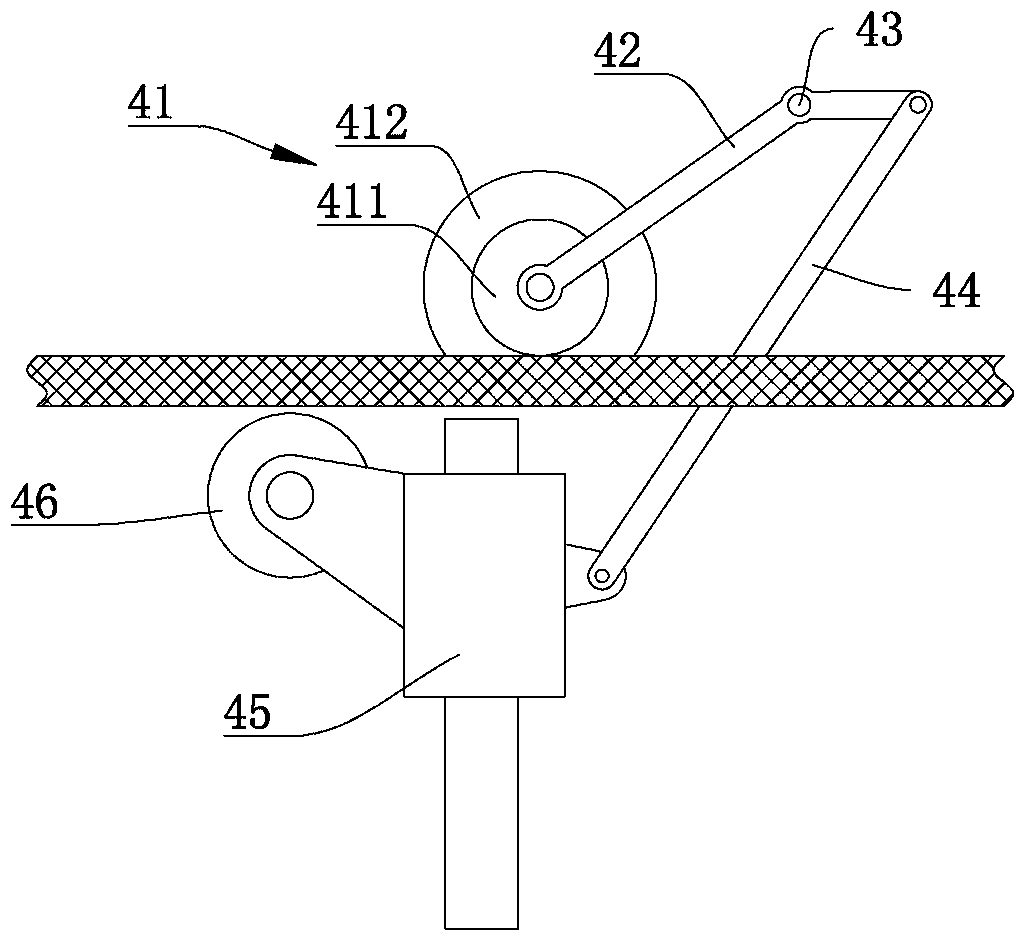

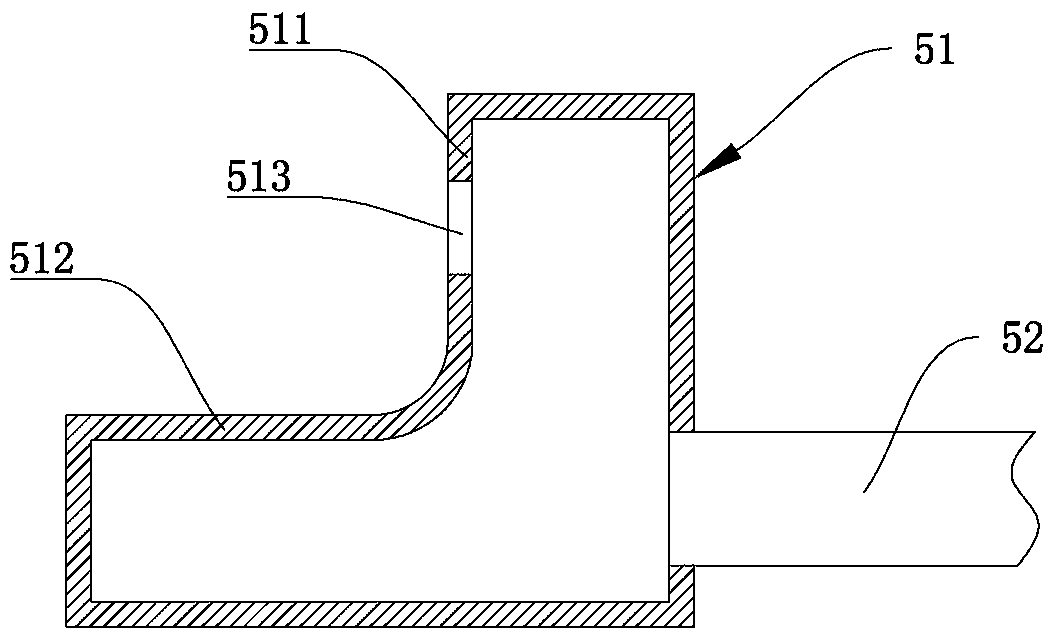

[0020] Example: such as Figure 1-3 As shown, a HDPE winding pipe production equipment includes a guiding device 4, a winding device, a heating device 5, a filling device 3 and a cooling device, and the winding device includes a reel 2 and a driving assembly that drives the reel 2 to rotate, The reel 2 is rotatably mounted on the frame 1, the reel 2 includes a rotating roller 21, fixed end plates arranged at both ends of the rotating roller 21, wherein a fixed end plate is fixedly installed on the frame 1, and the rotating roller 21 The rotation is installed on the fixed end plate and evenly distributed around the circumference of the fixed end plate, and the driving assembly drives the rotating roller 21 to rotate synchronously. Wherein the driving assembly is a sprocket chain, and a sprocket is arranged at the end of the rotating roller 21, and the chain is wound on the sprockets of all the rotating rollers 21, and the driving motor drives the rotating rollers 21 to rotate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com