Reciprocating type conveying device for tunnel cable pipeline

A conveying device, reciprocating technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems that cannot meet the needs of actual installation, etc., achieve simple structure, large contact area, and compact overall equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

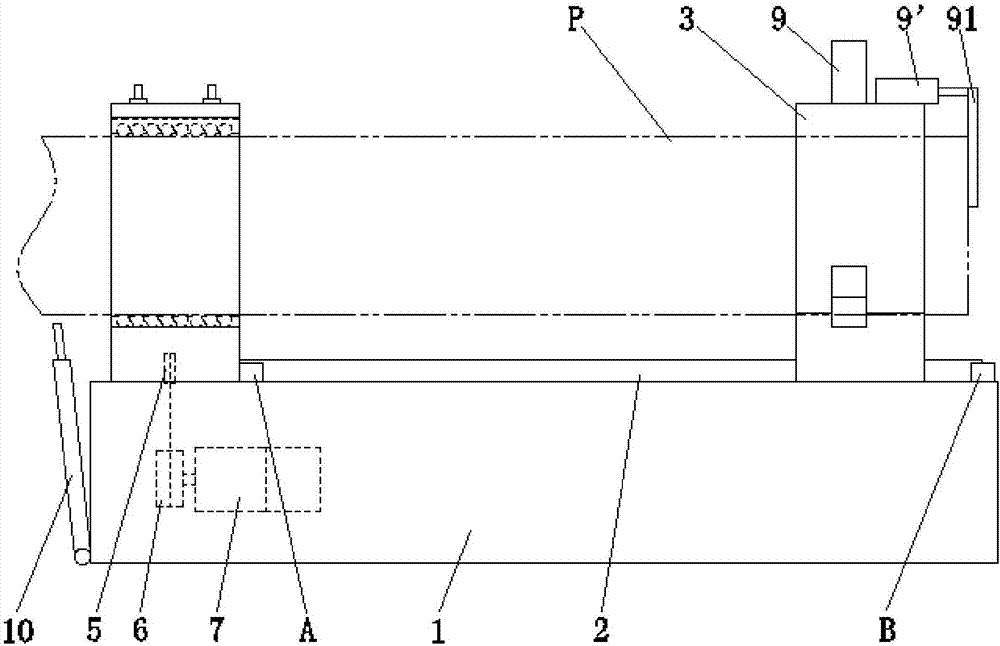

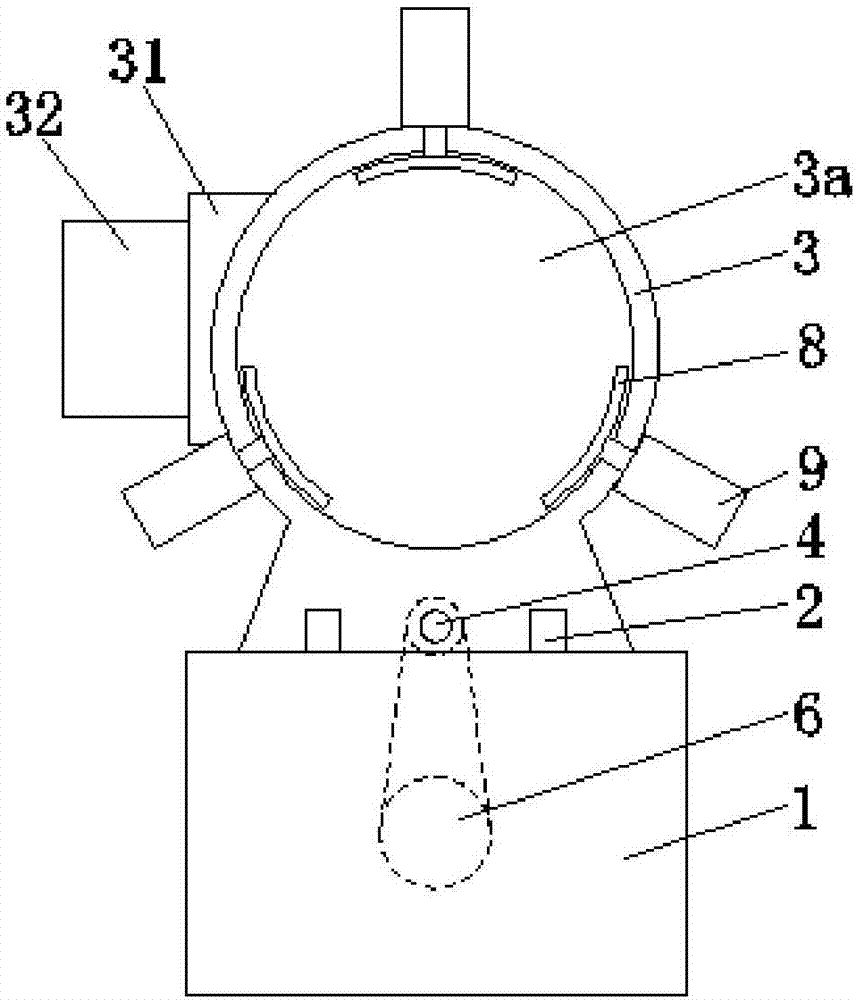

[0021] Such as figure 1 , figure 2 As shown, the four corners at the bottom of the bed 1 are equipped with rollers to facilitate movement. The front end of the bed 1 is provided with an overturning traction frame 10 , and the bottom end of the overturning traction frame 10 is hinged to the bottom of the front end of the bed 1 . The traction frame has two states of open and folded. When the traction frame is opened, it has a certain angle with the front surface of the bed, so as to be connected with the hook of the trailer, and the equipment is moved by the trailer; The front face fits together and takes up very little space. Two left and right parallel guide rails 2 are fixed on the top of the bed 1, and the sliding seat 3 slides and cooperates with the two guide rails 2 through the slider at the bottom thereof. As a preference, the upper part of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com