Double-acting spacial warped surface sealing sliding plate piston pump

A space-distorting, face-sealing technology, used in rotary piston pumps, rotary piston/oscillating piston pump components, and rotary piston machines, etc., can solve problems such as damage to the pump operating system and complex pump structure, and avoid problems such as The effect of excessive outlet pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

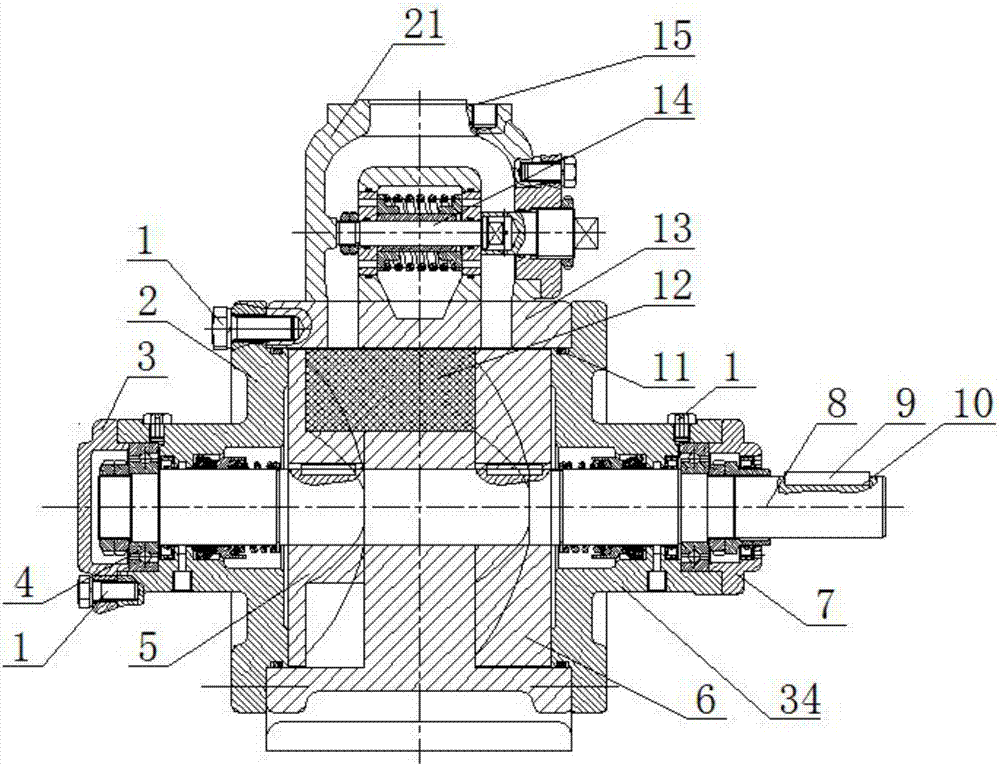

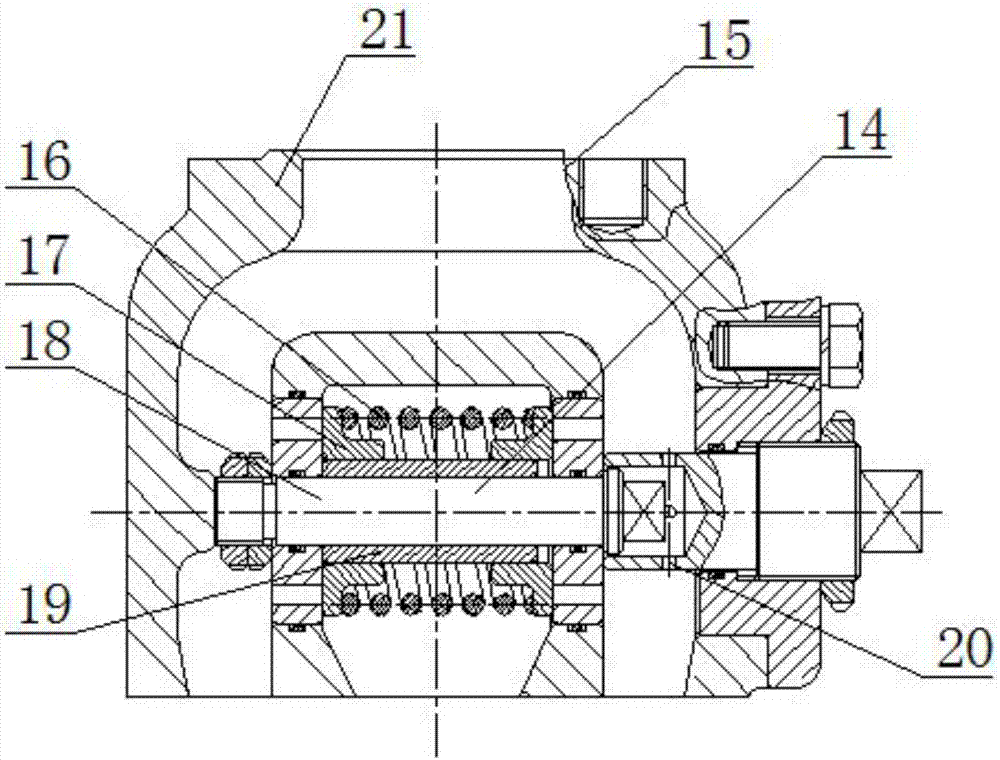

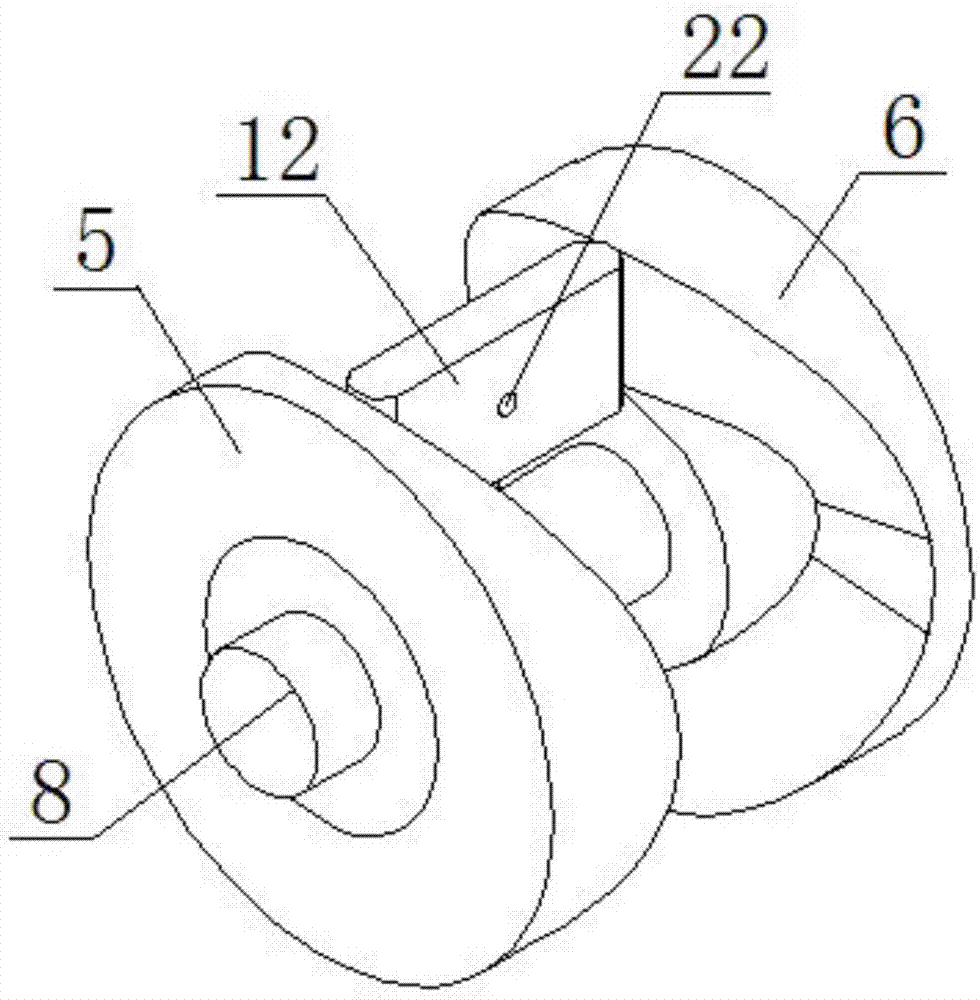

[0025] refer to Figure 1-Figure 9 , the present invention includes left pump cover 2, left end cover 3, left rotor 5, right rotor 6, right end cover 7, shaft 8, slide plate 12, pump body 13, safety valve 14, valve cover 21 and right pump cover 34 , the right end of the left pump cover 2 is fixed on the pump body 13 by the bolt 1, the left end cover 3 is fixed on the left end of the left pump cover 2 by the bolt 1; the right pump cover 34 is fixed on the right end of the pump body 13 by the bolt 1, the right pump The right end of the cover 34 is fixed with the right end cover 7 by the bolt 1; the left rotor 5 and the right rotor 6 are installed on the shaft 8, and the two ends of the shaft 8 are interference-fitted with the bearing 4, and the bearing 4 is interference-fitted on the left pump cover 2 Inside or inside the right pump cover 34; the opposite surfaces of the left rotor 5 and the right rotor 6 are twisted curved surfaces 28, a slide plate 12 is provided between the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com