Protection system and method of mechanical gearbox synchronizer

A mechanical gearbox and protection system technology, applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problem of reducing the service life of the synchronizer in the gearbox, damage to the synchronizer in the gearbox, and affecting driving Safety and other issues to achieve the effect of improving service life, avoiding early damage, and improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

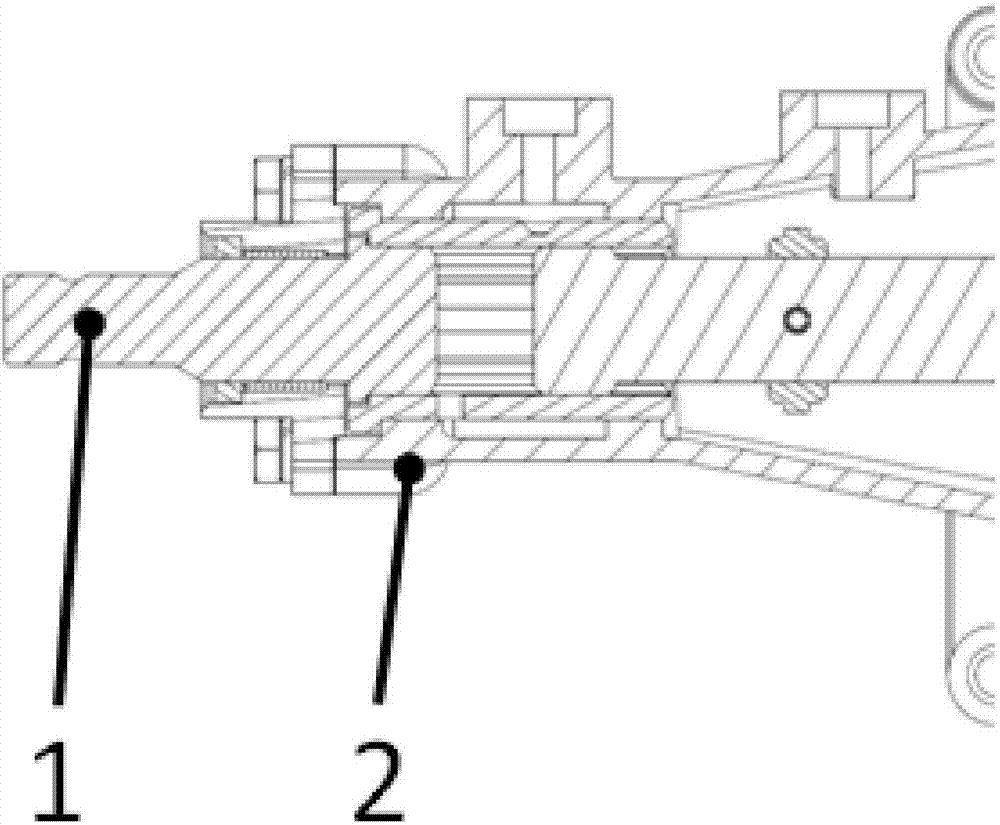

[0034] see figure 1 , is a traditional gear shifting device, the control housing 2 is equipped with a shift joint 1, and the shift joint 1 rotates axially under the action of an external force to realize the gear shifting of the gearbox 12.

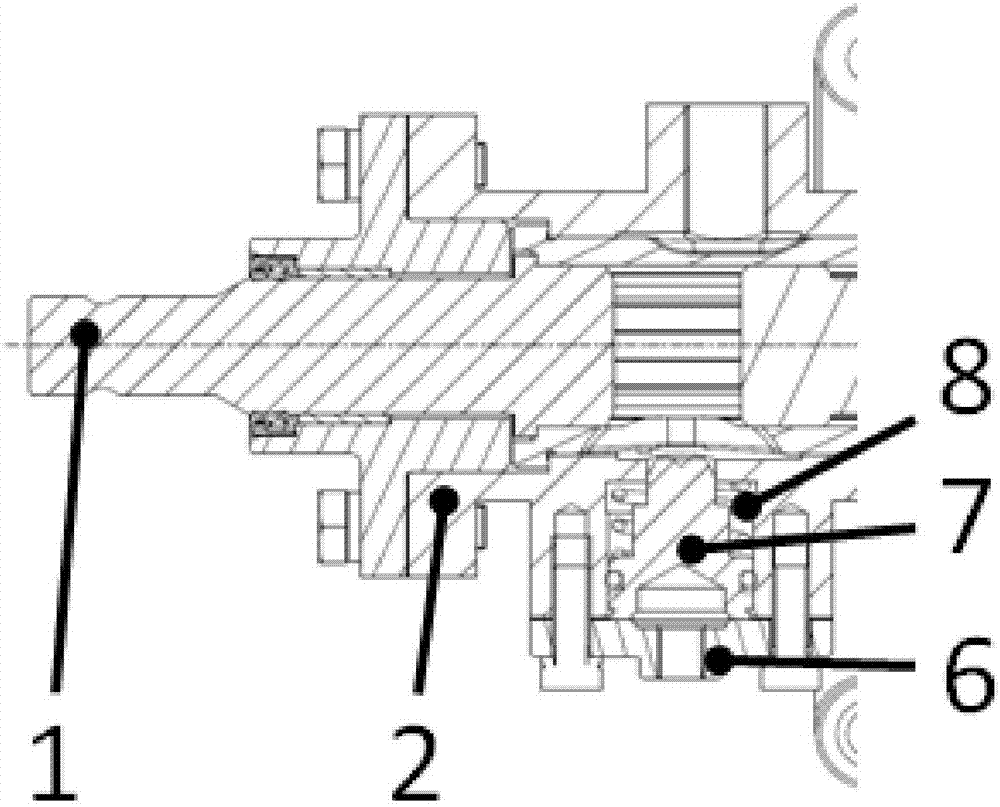

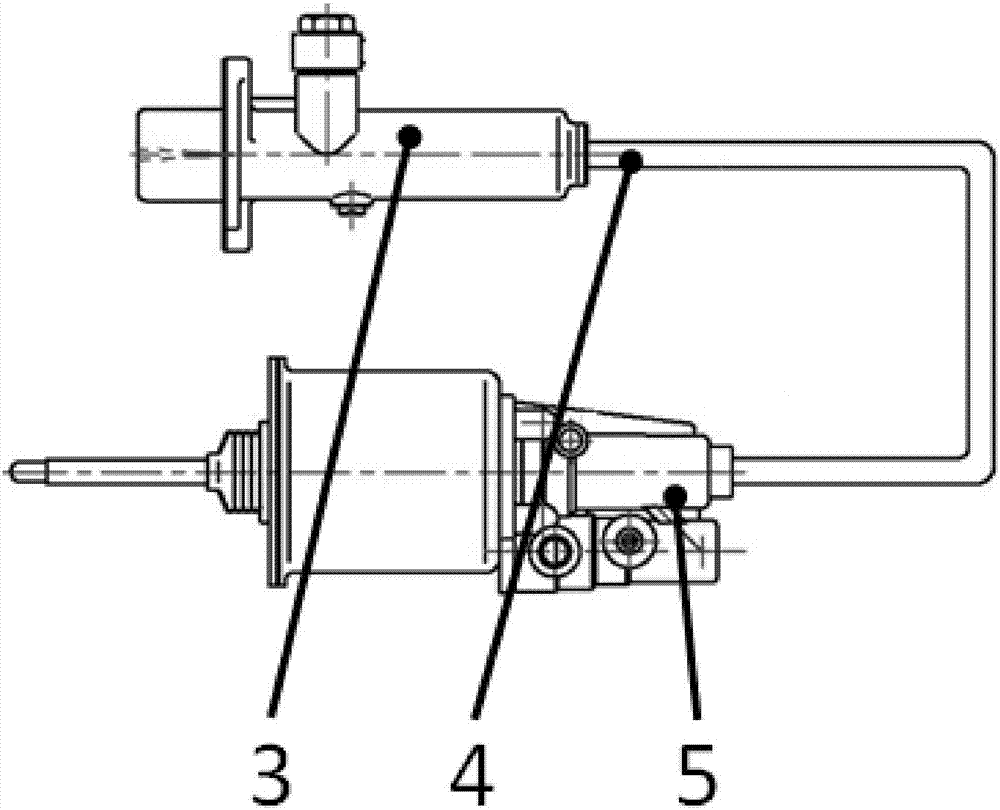

[0035] The mechanical gearbox synchronizer protection system of the present invention includes a shifting device, a pressure supply pipeline, a pipeline on-off control valve and a pressure supply source; see figure 2 , is the shifting device of the present invention, including a shifting joint 1, a shifting operation housing 2, a cover plate 6, a locking structure and a spring 8.

[0036] A shift connector 1 is arranged inside the shift operation housing 2, and a first groove is arranged on the shift connector 1; a through hole is provided on the part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com