Liquid phase mobility separating device, control method, and interface used for liquid chromatography-mass spectrometry

A separation device and mobility technology, applied in the field of mass spectrometry, can solve the problems of low ionization efficiency and low abundance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] In this embodiment, the influence of pressure on the sample migration time is analyzed through simulation theoretical calculation and experimental test respectively.

[0090]The simulation parameters are set as follows: the length of the capillary tube is 60cm, the inner diameter of the tube is 75μm, the reverse separation voltage is -10kV or no separation voltage is applied, the viscosity coefficient is 0.89mPa·S, the relative molecular weight of the sample is 1048, with 2 positive charges, the sample, etc. The effective radius is 1.2nm. The separation pressures at both ends of the separation channel are 10mbar, 15mbar, 20mbar, 30mbar, 40mbar, 50mbar respectively. Simulation results such as Figure 6-1 shown. It can be seen that when the reverse separation voltage is applied, as the pressure at both ends of the separation channel increases, the migration time of the substance shortens, and the migration time shortens abruptly from 10mbar to 15mbar, and gradually shor...

Embodiment 2

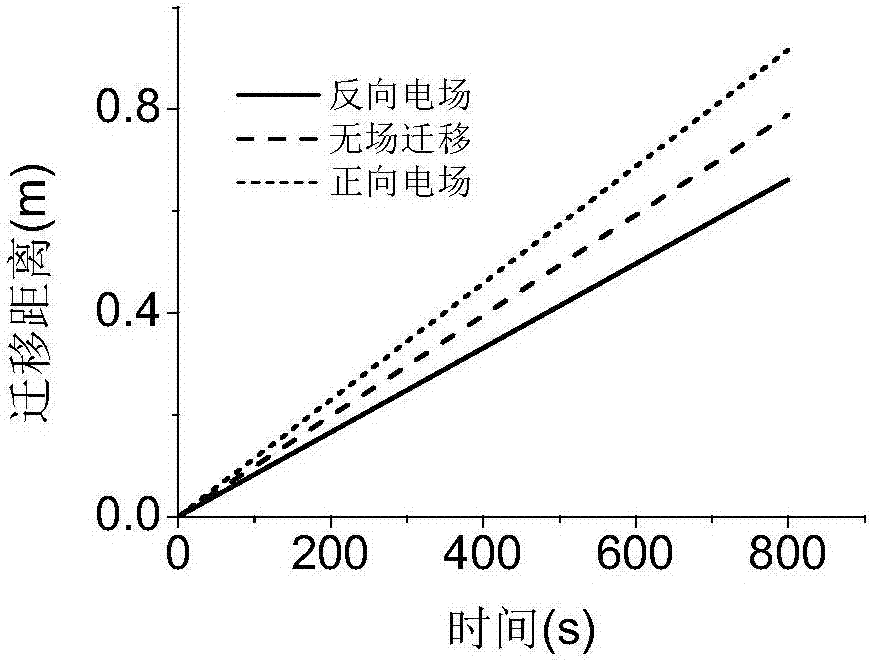

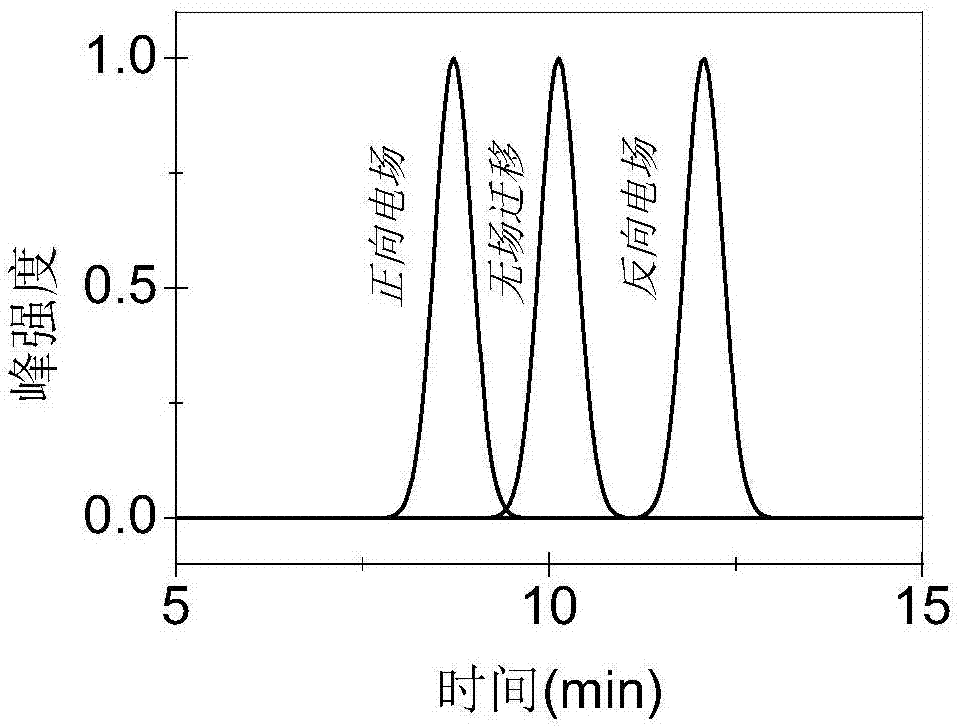

[0094] In this embodiment, the influence of the separation voltage on the sample migration time is analyzed through simulation theoretical calculation and experimental testing.

[0095] The simulation parameters are set as follows: the length of the capillary tube is 60 cm, the inner diameter of the tube is 75 μm, the separation pressure of the pumped buffer is 30 mbar, the viscosity coefficient is 0.89 mPa S, the relative molecular weight of the sample is 1048, with 2 positive charges, and the equivalent radius of the sample is 1.2nm. The reverse separation voltages are 0V, -100V, -200V, -500V, -1kV, -2kV, -5kV, -10kV, -15kV, -20kV, -25kV, -30kV. The result is as Figure 7-1 As shown, it can be seen that as the separation voltage increases, the migration time of the species gradually prolongs.

[0096] Experimental conditions: use the experimental conditions of the above-mentioned embodiment 1, specifically: the sample is angiotensin II of 1 mg / mL, the buffer solution is 20...

Embodiment 3

[0098] In this embodiment, the effect of the length of the separation capillary on the migration time of the sample is analyzed through simulation theoretical calculation and experimental testing.

[0099] The simulation parameters are set as follows: the inner diameter of the tube is 75 μm, the reverse separation field strength is -300 V / cm, the separation pressure of the pumped buffer solution is 30 mbar, the viscosity coefficient is 0.89 mPa·S, the relative molecular weight of the sample is 1048, with 2 positive charges , the sample equivalent radius is 1.2nm. The capillary lengths are 20cm, 40cm, 60cm, 80cm, and 100cm, respectively. Simulation results such as Figure 8-1 shown. It can be seen that when the separation field strength is constant, as the capillary length increases, the material migration time increases slowly at first, and then increases rapidly.

[0100] Experimental conditions: the sample is a mixed solution of angiotensin II with a final concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com