Polarized selection reflection type grating based on metal multilayer dielectric film

A multi-layer medium and selective reflection technology, applied in the field of reflection grating, can solve the problem of wide spectrum without 1550nm central band, and achieve high diffraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

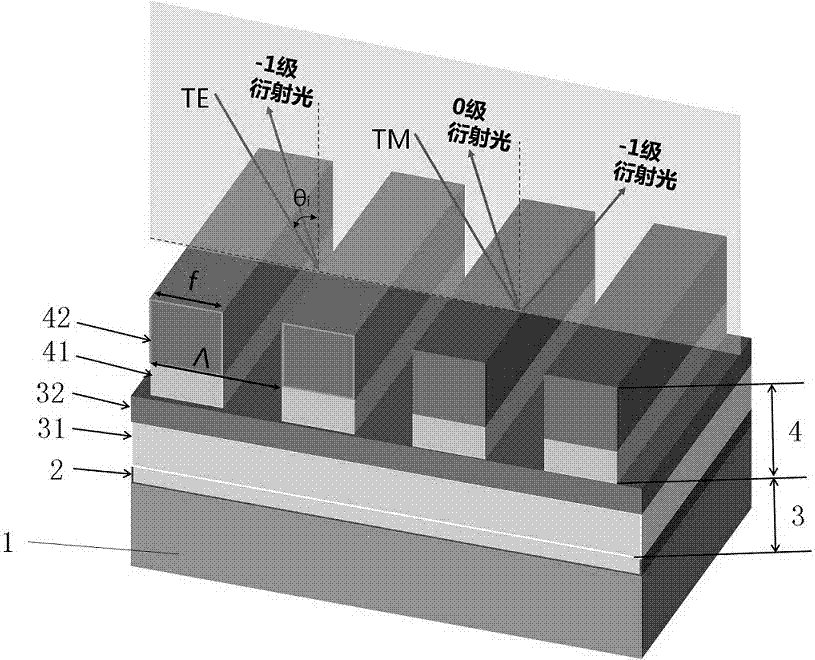

[0026]The polarization selective reflective grating based on the metal multilayer dielectric film for the central wavelength of 1550 nm includes a quartz substrate 1, a metal layer 2, a matching layer 3 and a grating etching layer 4 plated sequentially from the inside to the outside. The period of the grating etching layer 4 is 1243.62 nanometers, the duty ratio is 0.23, and the material of the first low refractive index film layer 41 in the inner layer of the grating etching layer 4 is SiO 2 , the thickness is 142.23 nanometers; the material of the first high refractive index film layer 42 in the outer layer is Si, and the thickness is 280.53 nanometers. The material of the second low refractive index film layer 31 in the inner layer of the matching layer 3 is SiO 2 , the thickness is 273.1 nanometers; the material of the second high refractive index film layer 32 of the outer layer is Si, and the thickness is 121.13 nanometers, and the thickness of the metal layer 2 is 200 n...

Embodiment 2

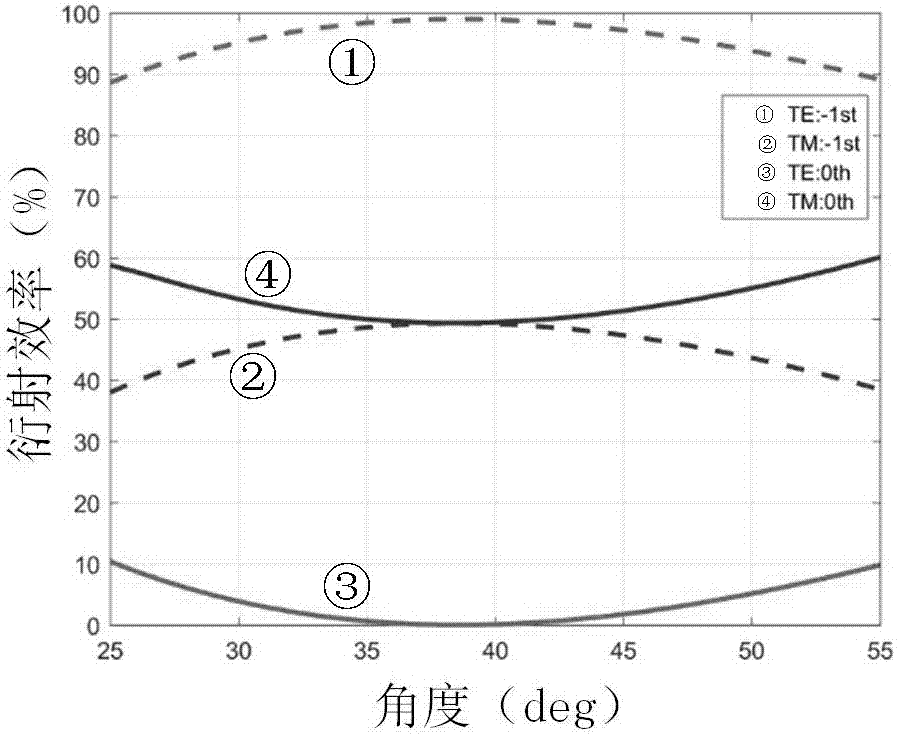

[0028] The polarization selective reflective grating based on the metal multilayer dielectric film for the central wavelength of 1550 nm includes a quartz substrate 1, a metal layer 2, a matching layer 3 and a grating etching layer 4 plated sequentially from the inside to the outside. The period of the grating etching layer 4 is 1243.62 nanometers, the duty ratio is 0.23, the inner layer is the first low refractive index film layer 41, and the material is SiO 2 , thickness 142.23 nanometers, the outer layer is the first high refractive index film layer 42, the material is Si, and the thickness is 280.53 nanometers; the inner layer of the matching layer 3 is the second low refractive index film layer 31, the material is SiO 2 , the thickness is 273.1 nanometers; the outer layer is the second high refractive index film layer 32, the material is Si, the thickness is 121.13 nanometers, and the thickness of the metal layer 2 is 200 nanometers. Such as Figure 4 As shown, at the in...

Embodiment 3

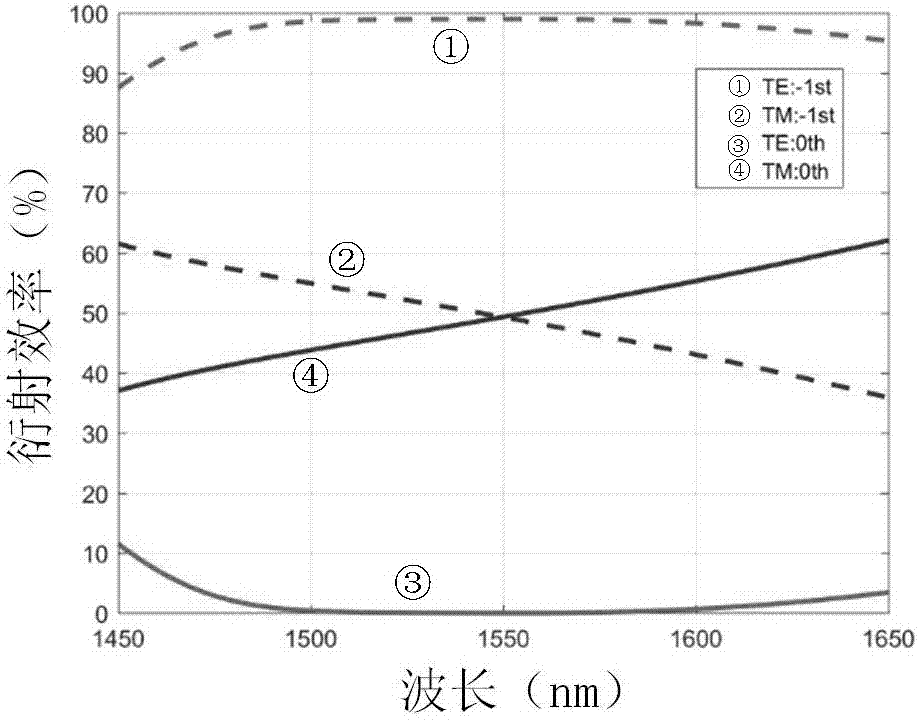

[0030] The polarization selective reflective grating based on the metal multilayer dielectric film for the central wavelength of 1550 nm includes a quartz substrate 1, a metal layer 2, a matching layer 3 and a grating etching layer 4 plated sequentially from the inside to the outside. The period of the grating etching layer 4 is 1243.62 nanometers, the duty ratio is 0.23, the inner layer is the first low refractive index film layer 41, and the material is SiO 2 , thickness 142.23 nanometers, the outer layer is the first high refractive index film layer 42, the material is Si, and the thickness is 280.53 nanometers; the inner layer of the matching layer 3 is the second low refractive index film layer 31, the material is SiO 2 , the thickness is 273.1 nanometers; the outer layer is the second high refractive index film layer 32, the material is Si, the thickness is 121.13 nanometers, and the thickness of the metal layer 2 is 200 nanometers. In addition, define the parameter Re=T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com