Panchromatic Micro-LED device based on inorganic/organic semiconductor hybrid structure and preparation method thereof

A technology of organic semiconductor and hybrid structure, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., and can solve the problems that there is no full-color Micro-LED.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1 Red-green-blue Micro-LED device based on Group III nitride / organic semiconductor hybrid structure

Embodiment approach

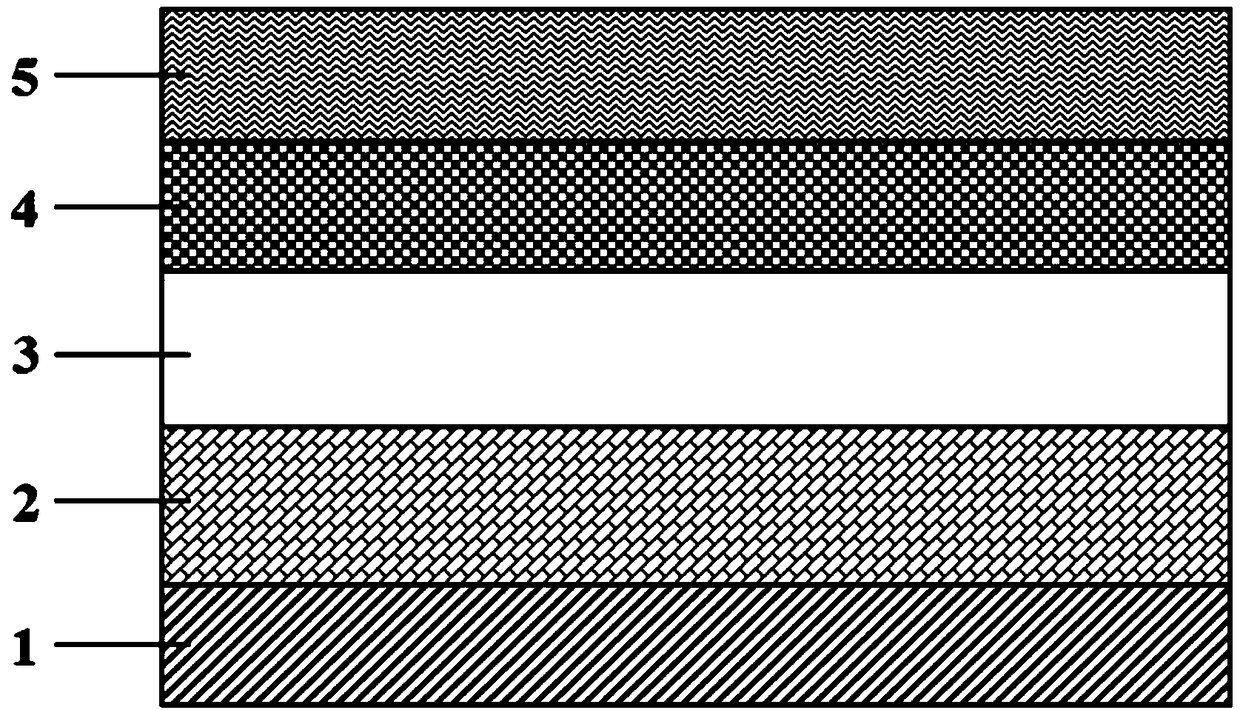

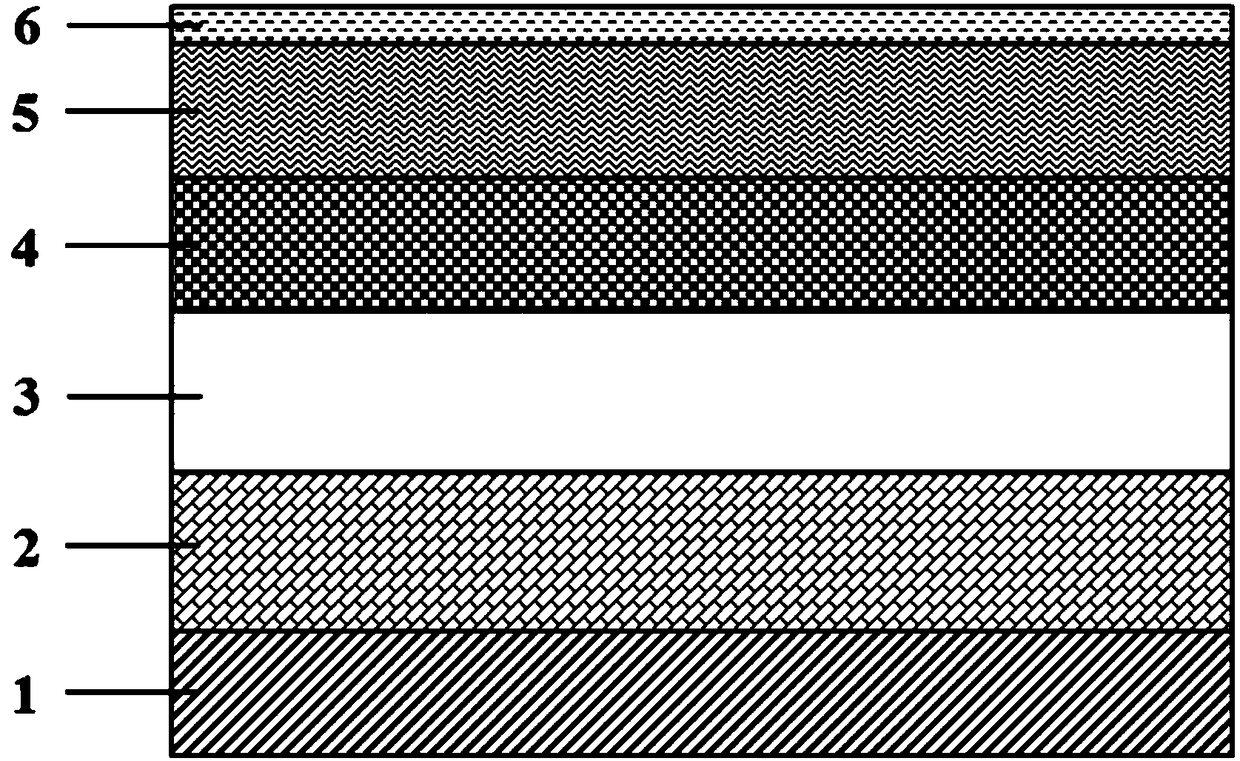

[0072] In this implementation case, blue LEDs and red and green organic LEDs are used to form a red-green-blue micron LED array device based on a III-nitride / organic semiconductor hybrid structure. Select In with p-n structure x Ga 1-x N / GaN quantum well blue LED epitaxial wafers, such as figure 1As shown, it includes a sapphire substrate 1; a GaN buffer layer 2 grown on the sapphire substrate; an N-type GaN layer 3 grown on the buffer layer; an In grown on the N-type GaN layer x Ga 1-x N / gallium nitride quantum well active layer 4; P-type gallium nitride layer 5 grown on the quantum well active layer; its emission wavelength is 450-470nm; red light organic light emitting diode adopts host material doped with red fluorescent or Made of phosphorescent small molecule materials, its luminous wavelength is 630-660nm; green organic light-emitting diodes are made of host materials doped with green fluorescent or phosphorescent small molecule materials, and their luminous wavelen...

Embodiment 2

[0089] The difference between this example and Example 1 lies in the N-type electrode of the inorganic LED and the organic light-emitting diode structure, and the structure of the inorganic LED still adopts Figure 1 to Figure 7 structure, so the following will focus on the N-type electrodes of inorganic LEDs and the structure of organic light-emitting diodes in detail:

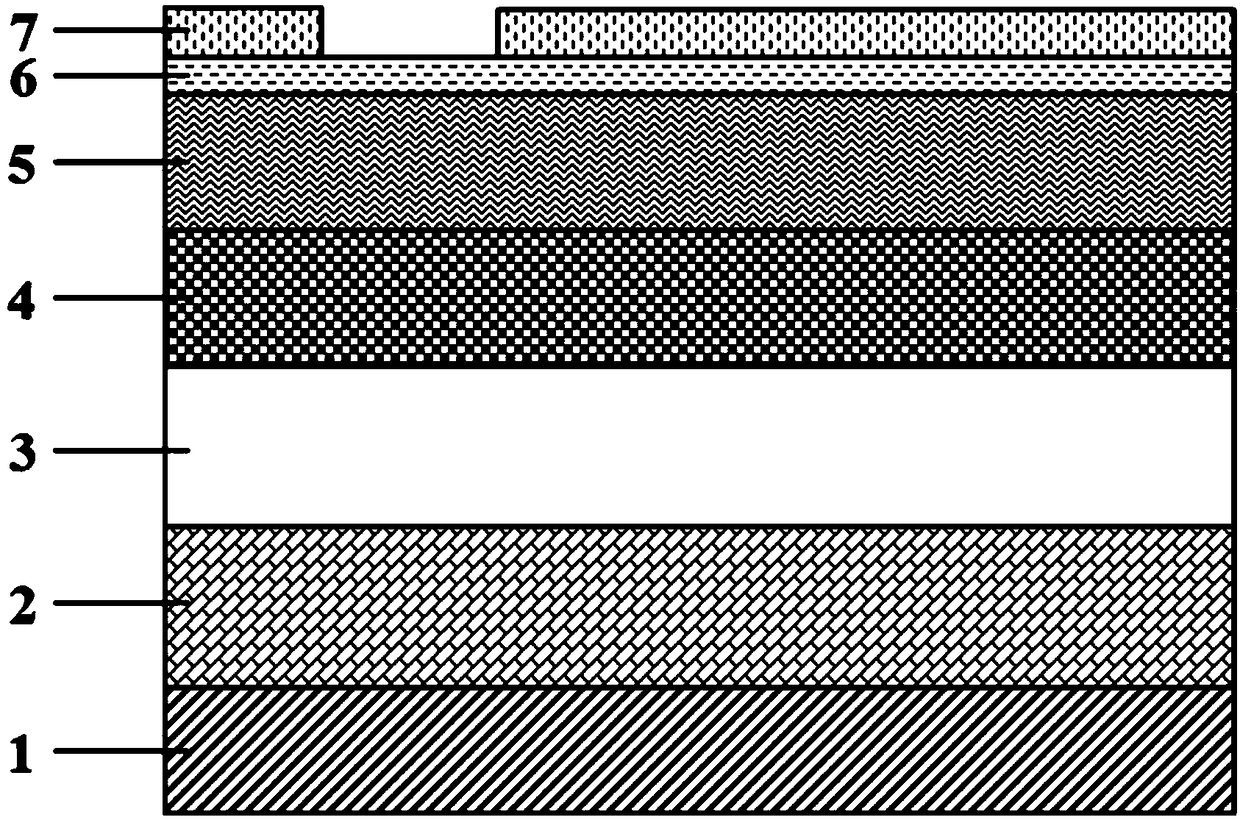

[0090] (1) if Figure 17 As shown, the plasma-enhanced chemical vapor deposition (PECVD) technique was used in Figure 7 A layer of SiO was deposited on the sample 2 or SiN x The dielectric layer film serves as the mask layer 6 . PECVD grown SiO 2 The process used for the dielectric layer is: silane (SiH 4 ) and nitrous oxide (N 2 O) mixed gas source, by chemical reaction SiH x +O→SiO 2 (+H 2 ) Deposit SiO on the P-type GaN layer heated to 350°C 2 The film layer has a thickness of 150-250nm. PECVD-grown SiN x The thin film process is as follows: silane (SiH 4 ) and nitrogen (N 2 ) mixed gas sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Luminous wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com