360-degree complete cycle type LED lamp filament based on purple light chips

A LED filament, all-round technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of affecting the service life of the light source, low color reproduction of the filament, blue light leakage from the filament, etc., to improve light output efficiency and heat dissipation, Improve interface compatibility, high light output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

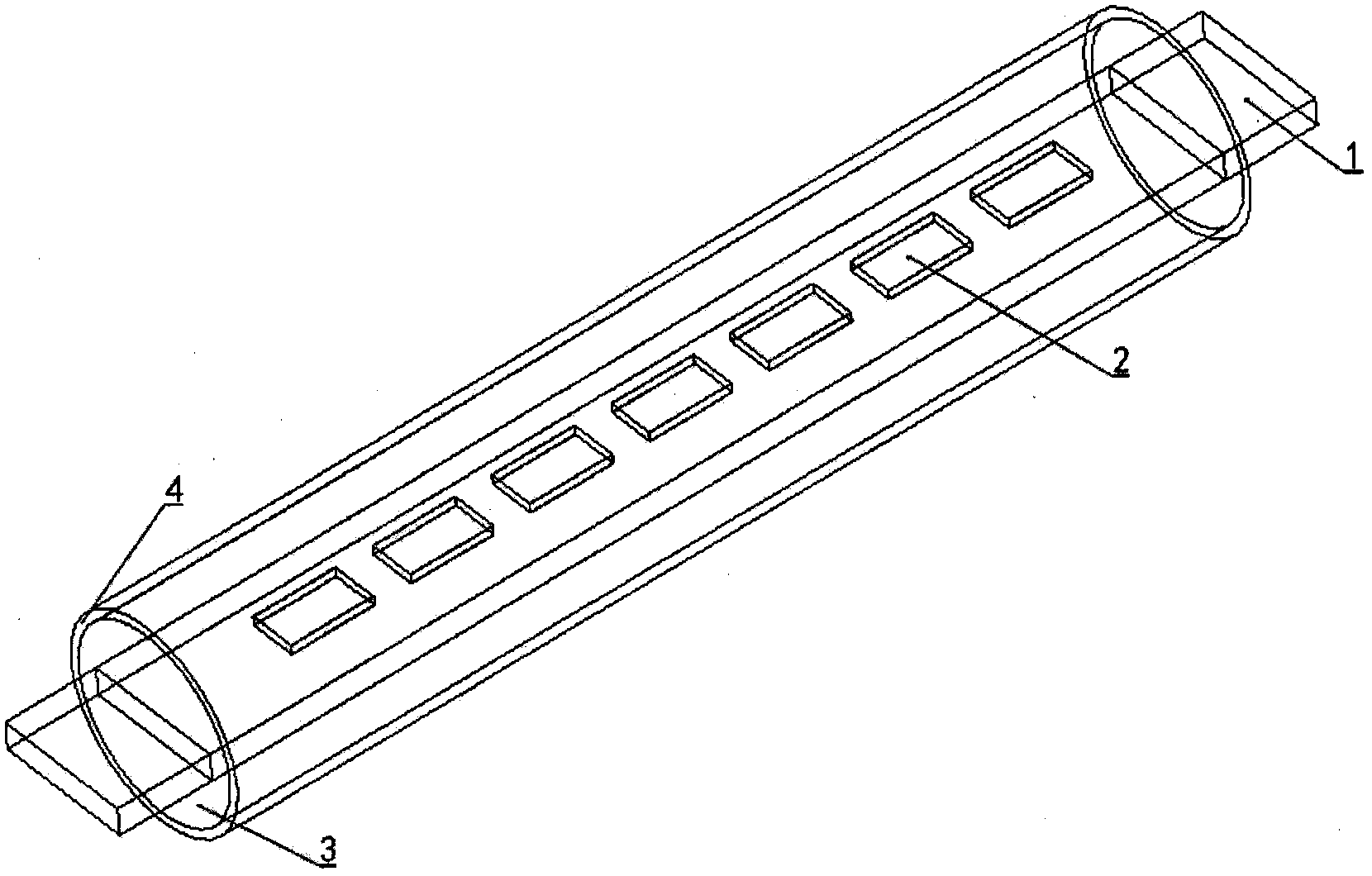

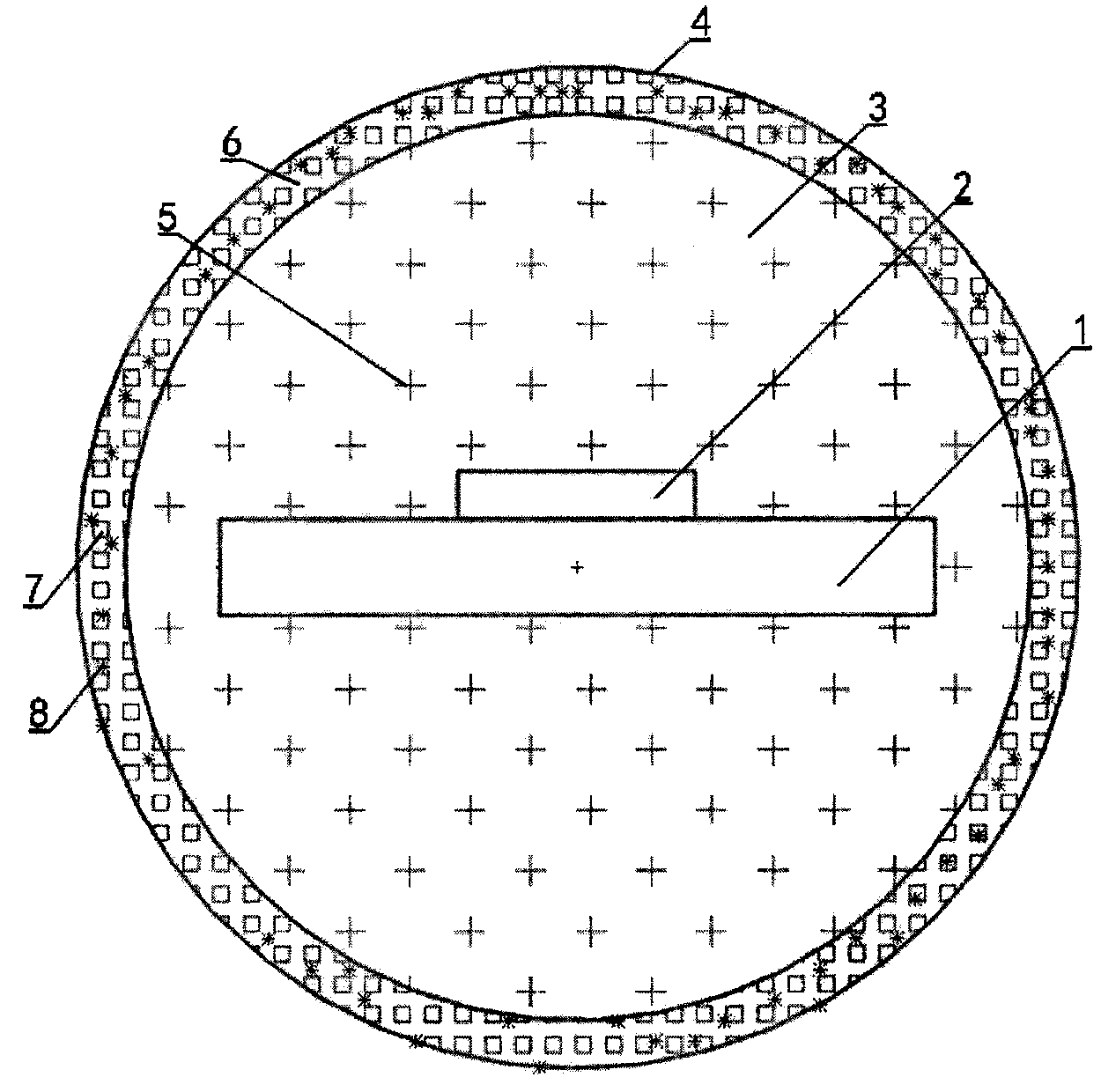

[0026] 1. Select the sapphire material as the substrate (1), arrange chips (2) with a peak wavelength of 360nm on the surface of the substrate (1) in an array; select silicone resin (6), multi-color phosphor powder (7), coupling Prepare the phosphor glue (4) by injection molding process, put the phosphor glue (5) and the substrate (1) into the mold, wherein the substrate (1) is relatively located in the center of the phosphor glue (5) Fixed position; select TiO 2 Inorganic nanoparticles (5) are mixed with transparent silica gel (3), and the mixture is evenly injected into the middle of the substrate (1) and phosphor glue (5); a 360° full-circle light-emitting LED filament based on a purple chip can be obtained .

Embodiment 2

[0028] 1. Select a transparent ceramic material as the substrate (1), and arrange chips (2) with a peak wavelength of 370nm on the front and back sides of the substrate (1) in an array; Powder (7) and coupling agent (8) are mixed to prepare fluorescent powder glue (4) through injection molding process, and phosphor powder glue (5) and substrate (1) are put into the mold, wherein substrate (1) is relatively positioned on the phosphor The center position of powder glue (5) is fixed; choose ZrO 2 Inorganic nanoparticles (5) are mixed with transparent silica gel (3), and the mixture is evenly injected into the middle of the substrate (1) and phosphor glue (5); a 360° full-circle light-emitting LED filament based on a purple chip can be obtained .

Embodiment 3

[0030] 1. Select the sapphire material as the substrate (1), arrange chips (2) with a peak wavelength of 380nm on the surface of the substrate (1) in an array; select silicone resin (6), multi-color phosphor powder of the phosphate system (7 ), the coupling agent (8) is mixed to prepare the fluorescent powder glue (4) through the injection molding process, and the phosphor powder glue (5) and the substrate (1) are put into the mold, wherein the substrate (1) is relatively located in the phosphor powder glue ( 5) The center position is fixed; choose TiO 2 Inorganic nanoparticles (5) are mixed with transparent silica gel (3), and the mixture is evenly injected into the middle of the substrate (1) and phosphor glue (5); a 360° full-circle light-emitting LED filament based on a purple chip can be obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com