Multi-operating-condition failure load based composite structure uncertainty optimization method

A composite material and optimization method technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as conservative structure and large safety factor, achieve good fatigue resistance and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

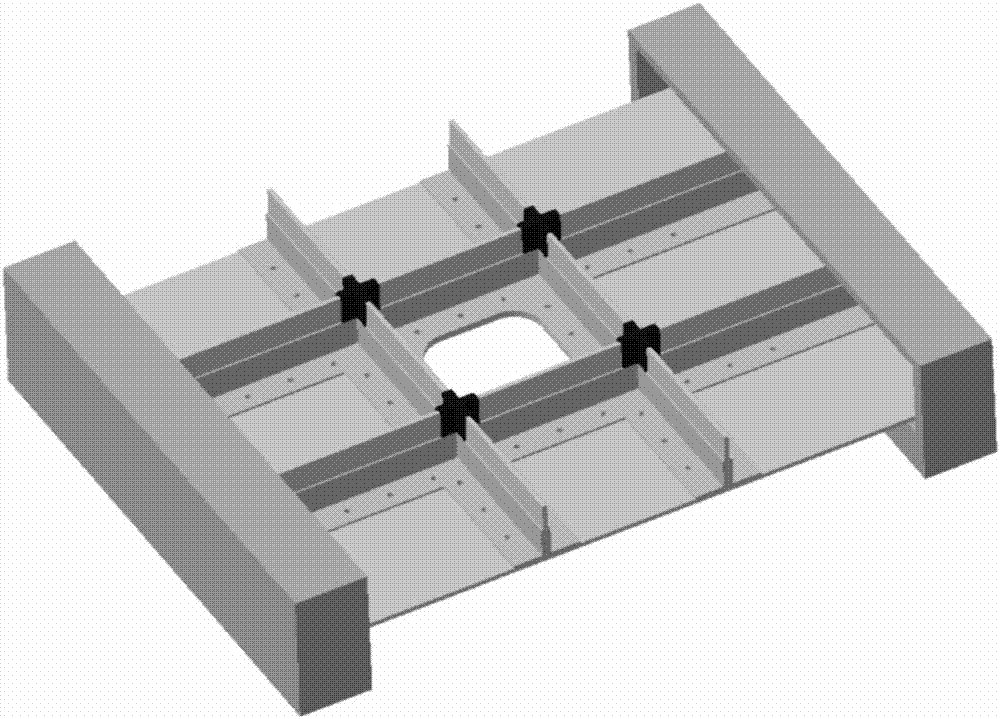

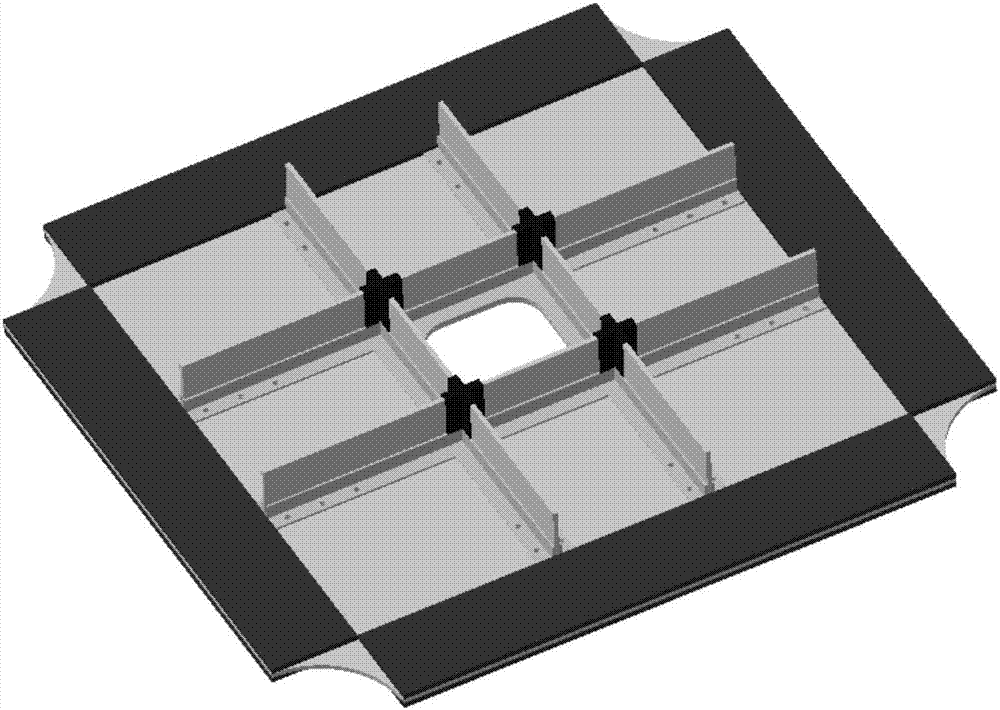

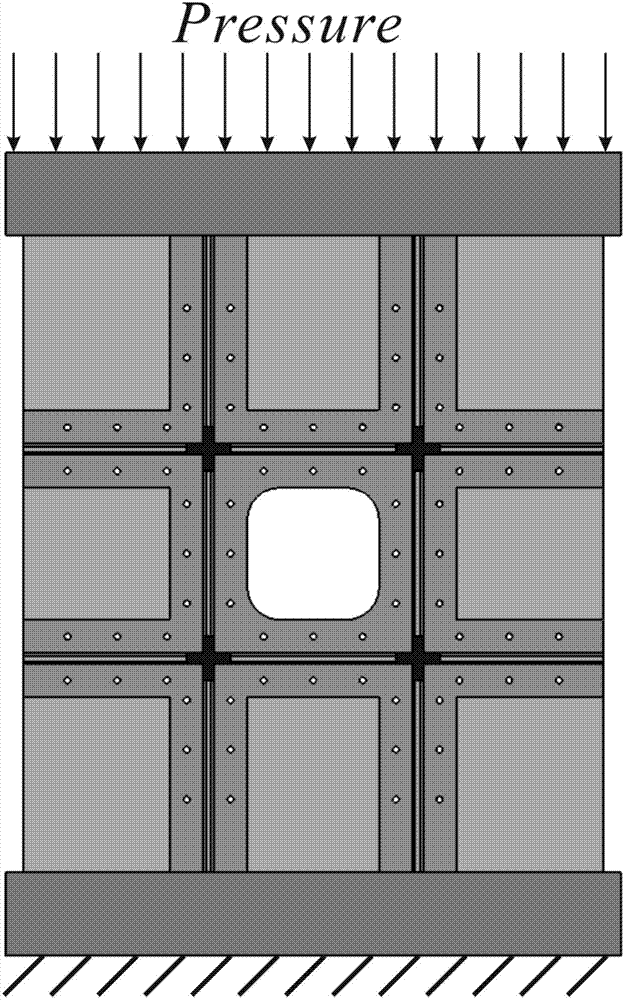

[0089] In order to fully understand the characteristics of the invention and its applicability to engineering practice, the invention optimizes the design of the proposed aircraft composite material stiffened panel wall panel structure. The aircraft skin rib panel is subjected to two load conditions, namely compression condition and shear condition, the design loads are 98kN and 121.0kN respectively, and the safety factor is 1.1. The model and loading conditions are as follows Figure 1-Figure 4 shown.

[0090] The composite material adopts carbon fiber fabric material, and the interval boundaries of its properties are listed in Table 1.

[0091] Table 1 Interval boundaries of uncertain variables

[0092] elastic parameters

lower bound

Upper Bound

Intensity parameter

lower bound

Upper Bound

E. 1 (GPa)

43 . 859

62 . 112

x t (MPa)

417.131

542.420

E. 2 (GPa)

43 . 85 9

62 . 112

x c (MPa)

120 . 781

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com