Intelligent machining workshop production planning and scheduling integration method

A production planning and intelligent machining technology, applied in the field of automation, which can solve the problems of difficulty in optimizing the manufacturing process and the inability to correct the production plan in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing, the present invention will be further described:

[0046] An integrated method for production planning and scheduling in an intelligent machining workshop, the method includes the following steps:

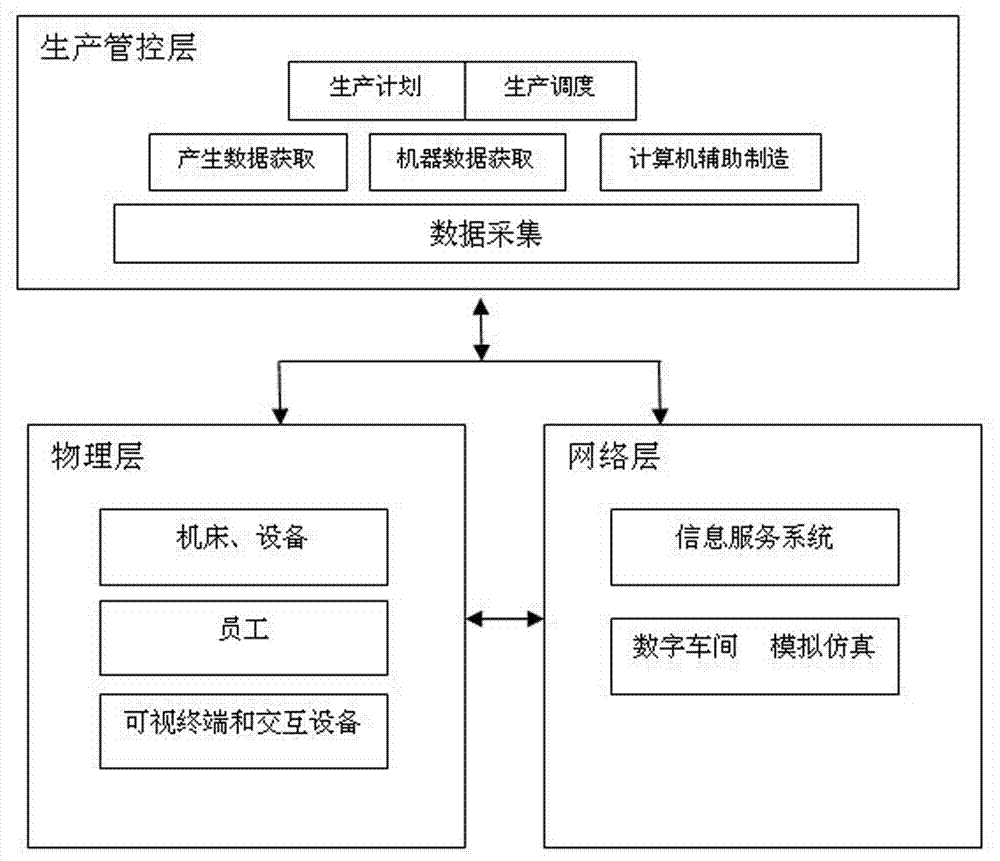

[0047] (1) System modeling: establish a physical system model of the intelligent workshop network composed of the physical layer, network layer and production control layer to provide basic conditions for the integration of production planning and scheduling;

[0048] (2) Data preparation: real-time collection, processing, transmission and storage of various status information on site, providing data preparation for decision-making of the planning and dispatching system;

[0049] (3) Order preparation: within each production planning cycle, analyze customer orders and convert them into specific machining orders;

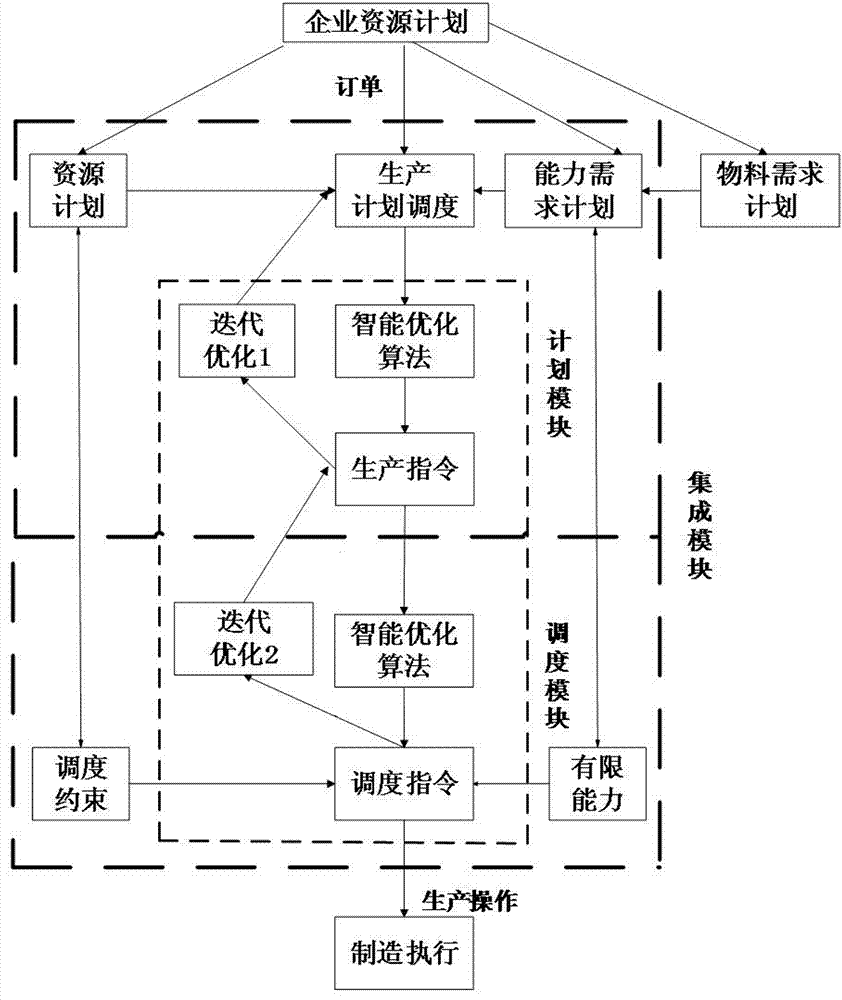

[0050] (4) Production planning and scheduling: Under the existing constraints, use the necessary resources from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com