Semi-solid continuous feeding and casting device and method

A casting equipment, semi-solid technology, applied in the field of casting, to achieve the effect of maintaining the heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

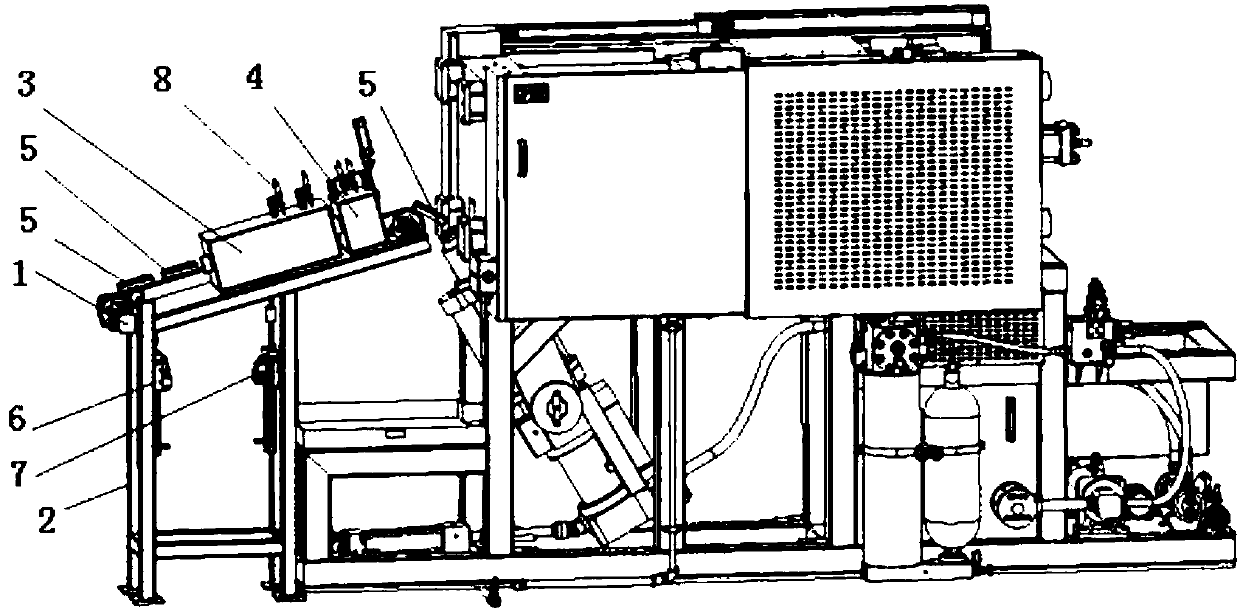

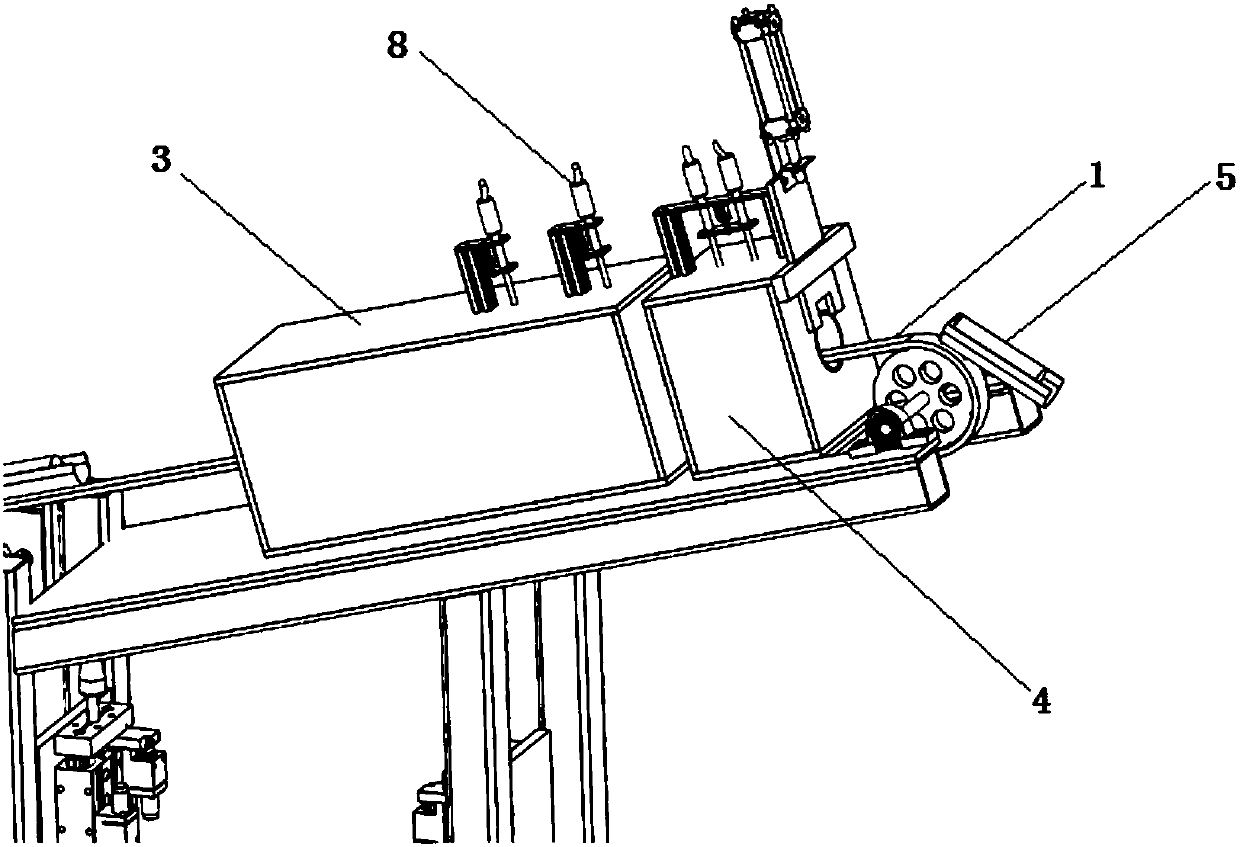

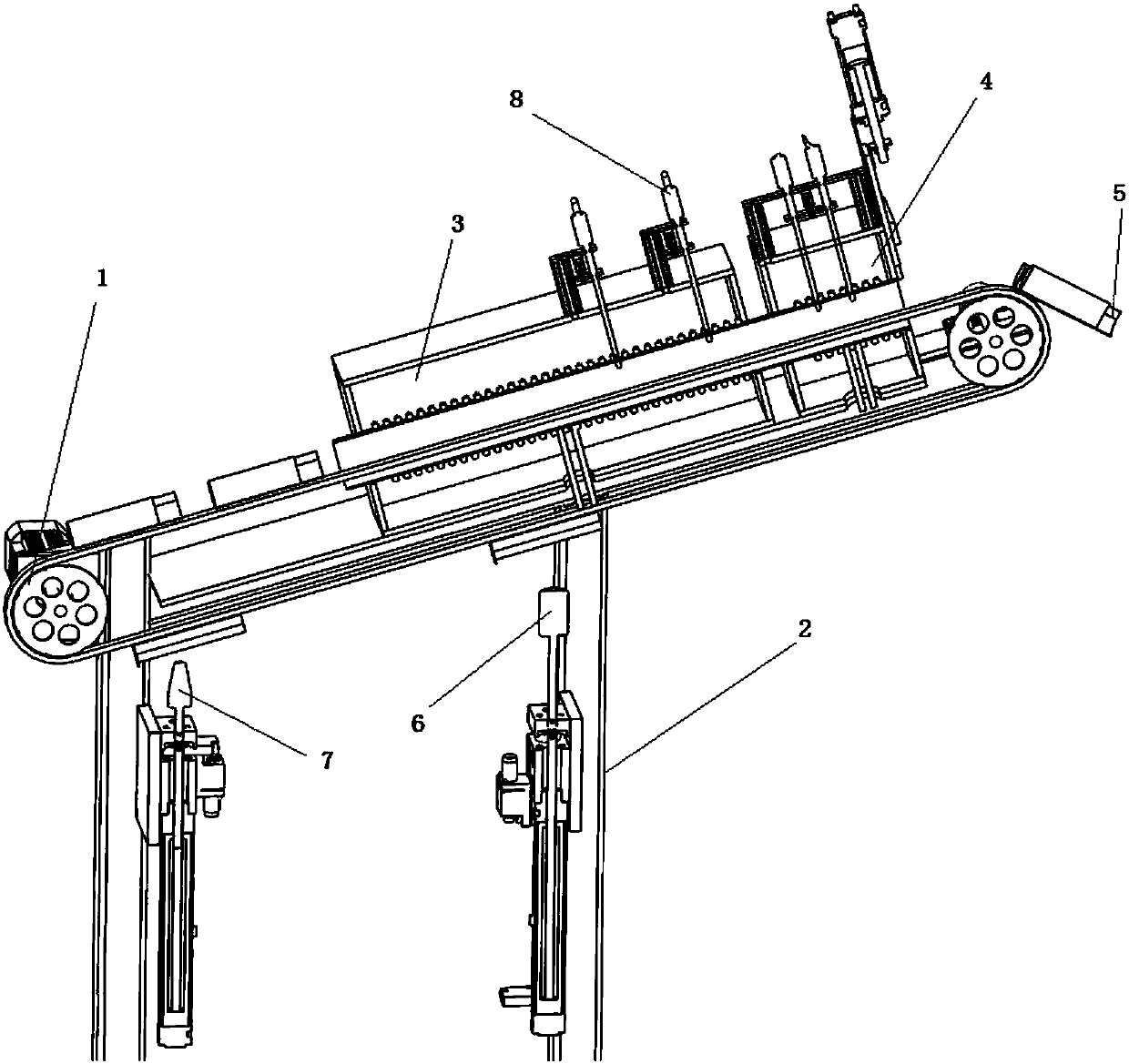

[0031] Such as figure 1 As shown, a kind of semi-solid continuous feeding casting equipment proposed by the present invention includes a conveying device 1, a support frame 2, a primary heater 3, a secondary heater 4, a stainless steel crucible 5, a cleaning device 6, a spraying device 7, Thermocouple 8, closed pipe 9

[0032] The conveying device 1 is obliquely tilted, and a plurality of stainless steel crucibles 5 are fixed on it. The middle part of the conveying device 1 is provided with a primary heater 3 and a secondary heater 4. The secondary heater 4 is arranged close to the casting equipment. Two thermocouples 8 are provided; a closed pipe 9 is arranged inside the primary heater and the secondary heater, and the closed pipe 9 is wound with an inductor outside, and the stainless steel crucible 5 undergoes primary heating and secondary heating in the closed pipe. Wherein the length of the primary heater 3 is longer than that of the secondary heater 4 . The support fram...

Embodiment 2

[0035] The invention discloses a semi-solid continuous feeding casting method, which is carried out according to the following steps:

[0036] Step 1. The stepping motor drives the transmission wheel of the transmission device to work. During the transmission process, put the semi-solid billet into the stainless steel crucible;

[0037] Step 2. The crucible is transported to the primary heating zone, and the induction heating starts to work. The thermocouple above the rod performs feedback calculation on the measured aluminum rod temperature and reaches the preset temperature, and then it is transmitted to the secondary heating zone through a closed pipeline;

[0038] Step 3. The thermocouple above the bar in the secondary heating zone performs feedback calculation on the measured aluminum bar temperature and stops heating when it reaches the preset temperature;

[0039] Step 4. Pour the crucible into the barrel of the extruder in the way of turning over and pouring the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com