Three-dimensional laser marking method and device and storage medium

A three-dimensional laser and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low processing accuracy and poor marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

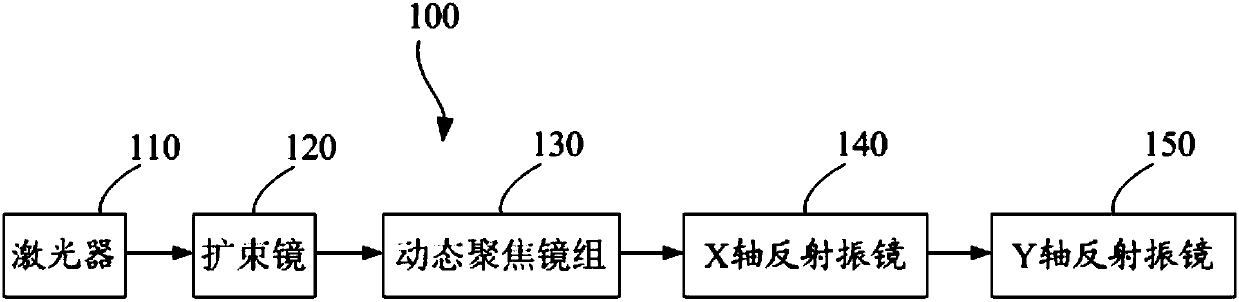

[0043] figure 1 It is a schematic structural diagram of a front-focus galvanometer-type three-dimensional laser marking system 100 according to an embodiment. The front-focus galvanometer-type 3D laser marking system 100 includes a laser 110 , a beam expander 120 , a Z-axis dynamic focusing lens group 130 , an X-axis galvanometer 140 and a Y-axis galvanometer 150 along the optical path of the laser. The front focusing galvanometer three-dimensional laser marking system 100 also includes a control unit.

[0044] The laser 110 is used to generate a laser beam for marking. The beam expander 120 expands and collimates the laser beam and adjusts it to a parallel beam. The Z-axis dynamic focus lens group 130 is used to adjust the focal le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com