A method for multi-stage increase-decompression strengthening SBR excess sludge reduction and equipment for sludge reduction

A technology for sludge reduction and excess sludge, applied in chemical instruments and methods, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of low ozone solubility and low actual utilization rate, etc. To improve the treatment efficiency, improve the effect, and achieve the effect of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

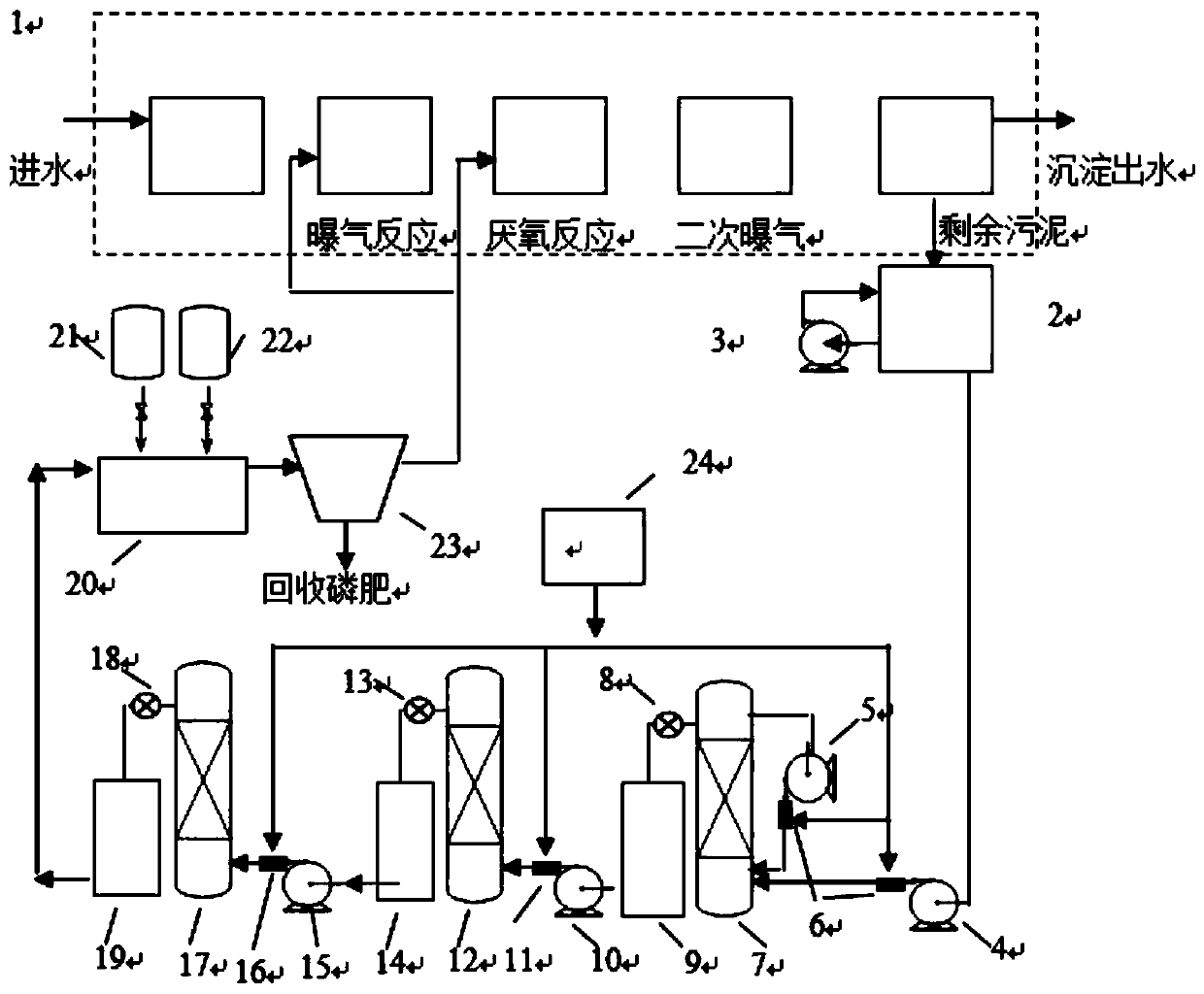

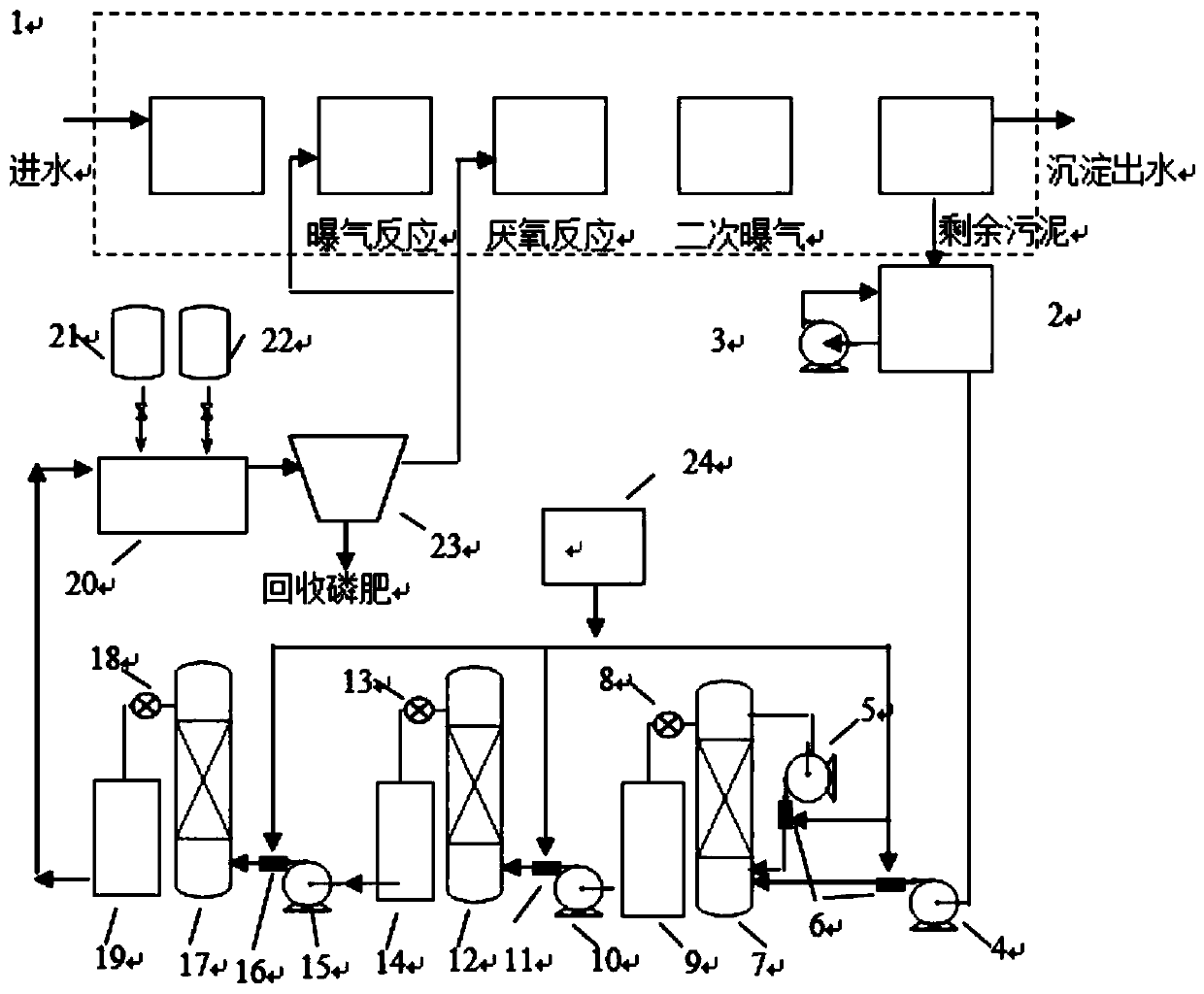

[0051] The present invention is aimed at a small sewage treatment plant that adopts the SBR treatment process. The scale of the treatment plant is small, and treatment processes such as sludge digestion cannot be used, and the sludge reduction treatment process based on ozonation is adopted. The excess sludge discharged from the SBR sedimentation process first enters the buffer / crushing reactor. An internal circulation pump is installed in the reactor, and the high-speed rotation of the pump impeller is used to break the sludge flocs. The crushed sludge mixture enters the first reactor in sequence. The first, second, and third stages of increased-pressure reduction enhanced sludge reduction reactors. The pressurized reaction column is composed of a closed cylindrical reactor, a supporting booster pump, an ejector and supporting pipelines. The ratio of height to diameter is 1:0.6, the inlet of the mixed solution is at the bottom of the reactor, a pressure reducing valve is set ...

Embodiment 2

[0055] The present invention is aimed at a small sewage treatment plant that adopts the SBR treatment process. The scale of the treatment plant is small, and treatment processes such as sludge digestion cannot be used, and the sludge reduction treatment process based on ozonation is adopted. The excess sludge discharged from the SBR sedimentation process first enters the buffer / crushing reactor. An internal circulation pump is installed in the reactor, and the high-speed rotation of the pump impeller is used to break the sludge flocs. The crushed sludge mixture enters the first reactor in sequence. The first, second, and third stages of increased-pressure reduction enhanced sludge reduction reactors. The pressurized reaction column is composed of a closed cylindrical reactor, a supporting booster pump, an ejector and supporting pipelines. The ratio of height to diameter is 1:1, the inlet of the mixed solution is at the bottom of the reactor, a pressure reducing valve is instal...

Embodiment 3

[0059] The invention is aimed at a medium-sized sewage treatment plant, adopts the SBR treatment process, and adopts the ozonated sludge reduction treatment process. The excess sludge discharged from the SBR sedimentation process first enters the buffer / crushing reactor. An internal circulation pump is installed in the reactor, and the high-speed rotation of the pump impeller is used to break the sludge flocs. The crushed sludge mixture enters the first reactor in sequence. The first, second, and third stages of increased-pressure reduction enhanced sludge reduction reactors. The pressurized reaction column is composed of a closed cylindrical reactor, a supporting booster pump, an ejector and supporting pipelines. The ratio of height to diameter is 1:0.8, the inlet of the mixed solution is at the bottom of the reactor, a pressure reducing valve is installed on the upper part of the reactor, and a stainless steel screen loaded with MnO is installed inside the reactor, the scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com