Poly(polyphenol) coated nitrification inhibitor as well as preparation method and application thereof

A technology of nitrification inhibitors and polyphenols, which is applied in the fields of application, agricultural gas emission reduction, fertilizer mixture, etc., can solve the problems of nitrification inhibitors being easily washed out, deliquescence, reducing the inhibition of nitrification, etc., and achieves a small anti-nitrification effect , good pH responsiveness, and obvious slow-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

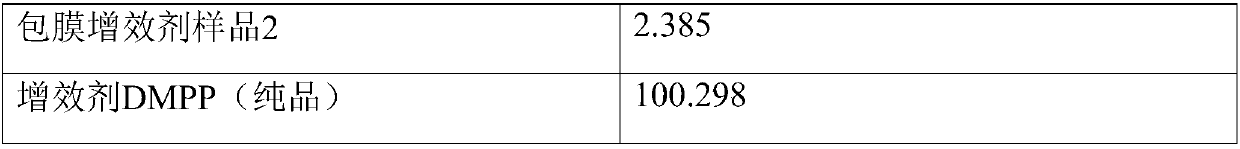

Embodiment 1

[0032] Utilizing the low solubility of nitration inhibitor DMPP in organic solvents, first DMPP (6g) was dispersed in a container equipped with absolute ethanol solution (500ml), then dopamine (0.5g) was completely dissolved in this solution, and three Ethylamine (15ml) was reacted under vigorous stirring (48h), and the product was simply settled or centrifuged, and dried completely at room temperature or in an oven to obtain polydopamine-coated DMPP, which was recorded as coating synergist sample 1.

[0033] The TEM characterization results of the prepared samples are as follows: figure 1 shown by figure 1 It can be seen that polydopamine was successfully coated on the surface of DMPP.

Embodiment 2

[0035] In this embodiment, 6 g of DMPP, 0.5 g of dopamine, 2.8 g of octadecylamine, and 5 ml of piperidine are used. The raw materials are simultaneously added to 500 ml of ethanol solution and reacted for 48 hours. After drying completely, polydopamine-coated DMPP was obtained, which was recorded as coating synergist sample 2.

Embodiment 3

[0037] Utilize the low solubility of nitrification inhibitor DMPP in organic solvents, at first DMPP (200g) is put into coating instrument fluidized bed coater, dopamine ethanol solution (15mg / ml) and triethylamine ethanol solution (20mg / ml) ml) The organic amine solution is connected by a two-way connection and sprayed on the surface of DMPP at the same time. The spraying of the two solutions is a cycle. This method requires multiple sprays to achieve the thickness of the layer. The solution is 20ml each time, and the number of cycles for 10 times. After spraying, take out the sample and dry it completely at room temperature or in an oven to obtain polydopamine-coated DMPP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com