Special tyre-based rubber composition for engineering mechanical tire

A rubber composition and engineering machinery technology, applied in the field of tire rubber, can solve problems such as the inability to meet the use requirements of mobile cranes, and achieve the effect of improving basic mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

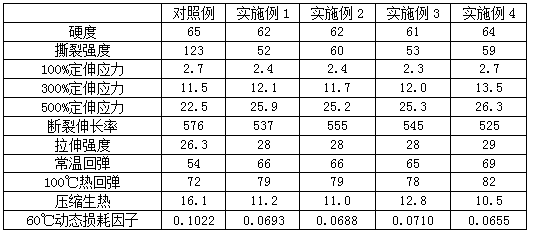

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with embodiment:

[0008] Contains the following steps:

[0009] One-stage mixing: Start the internal mixer (the rotor type is ZZ2 rotor), set the rotor speed of the internal mixer to 50 rpm, add natural rubber, zinc oxide, stearic acid, anti-aging agent and carbon black (including white carbon black), Mix to 155°C for debinding.

[0010] The first standing still: cool the rubber to room temperature after a period of mixing.

[0011] Two-stage mixing: Start the internal mixer (the rotor type is ZZ2 rotor), set the rotor speed of the internal mixer to 45 rpm, and mix the first-stage masterbatch to 155°C for debinding.

[0012] The second standing still: cool the rubber material to room temperature after the second-stage mixing.

[0013] Final refining: start the internal mixer (rotor type is ZZ2 rotor), set the rotor speed of the internal mixer to 19 rpm, add the second-stage masterbatch, N-tert-buty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com