Parallel bioreactor system

A bioreactor and control system technology, applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc., can solve the problem of high-throughput screening and culture of samples or cell clones. Process optimization, inability to control the microenvironment of the culture container, etc., to achieve the effects of small shear force, increased growth density, and high dissolved oxygen level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be described below with reference to the drawings. The following descriptions are merely exemplary and are not intended to limit the protection scope of the present invention.

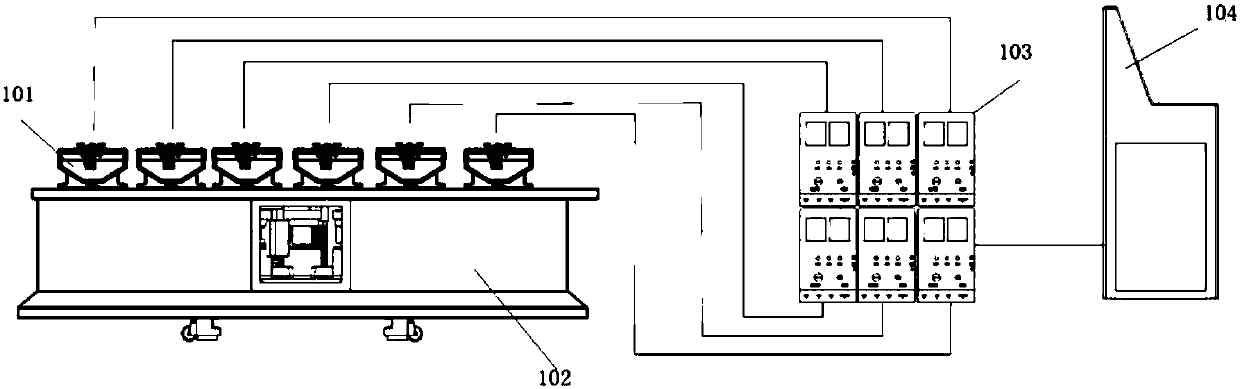

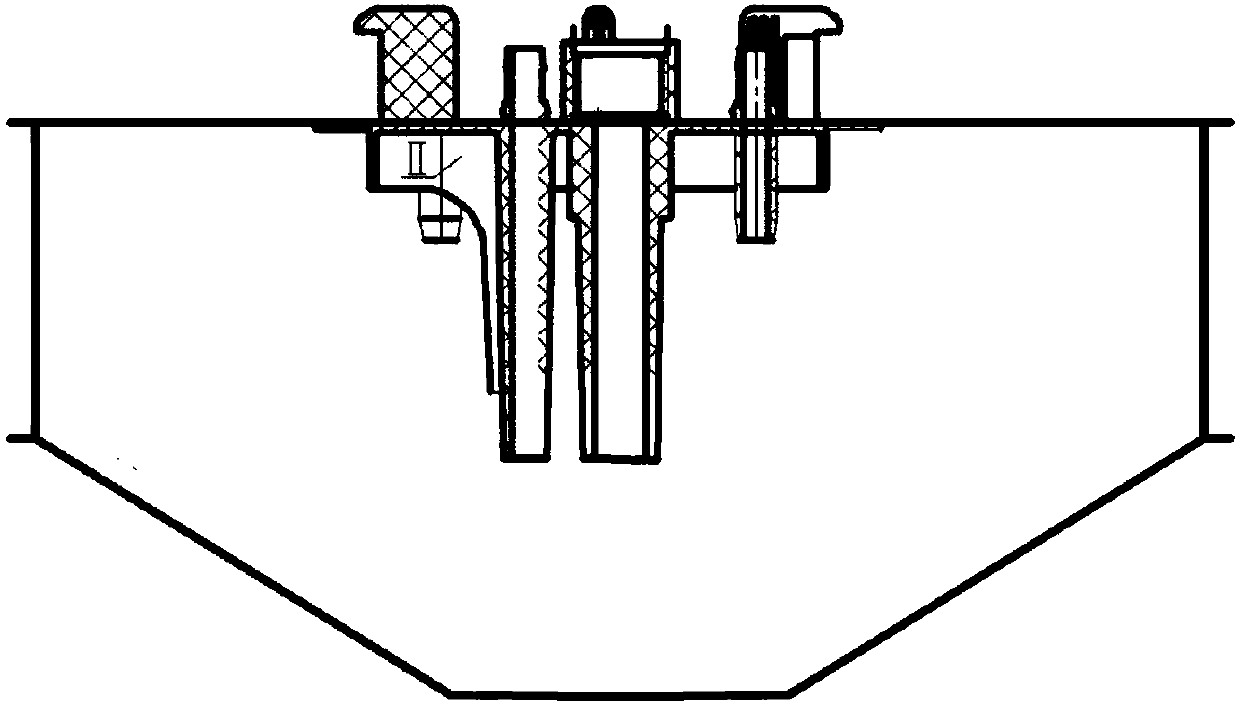

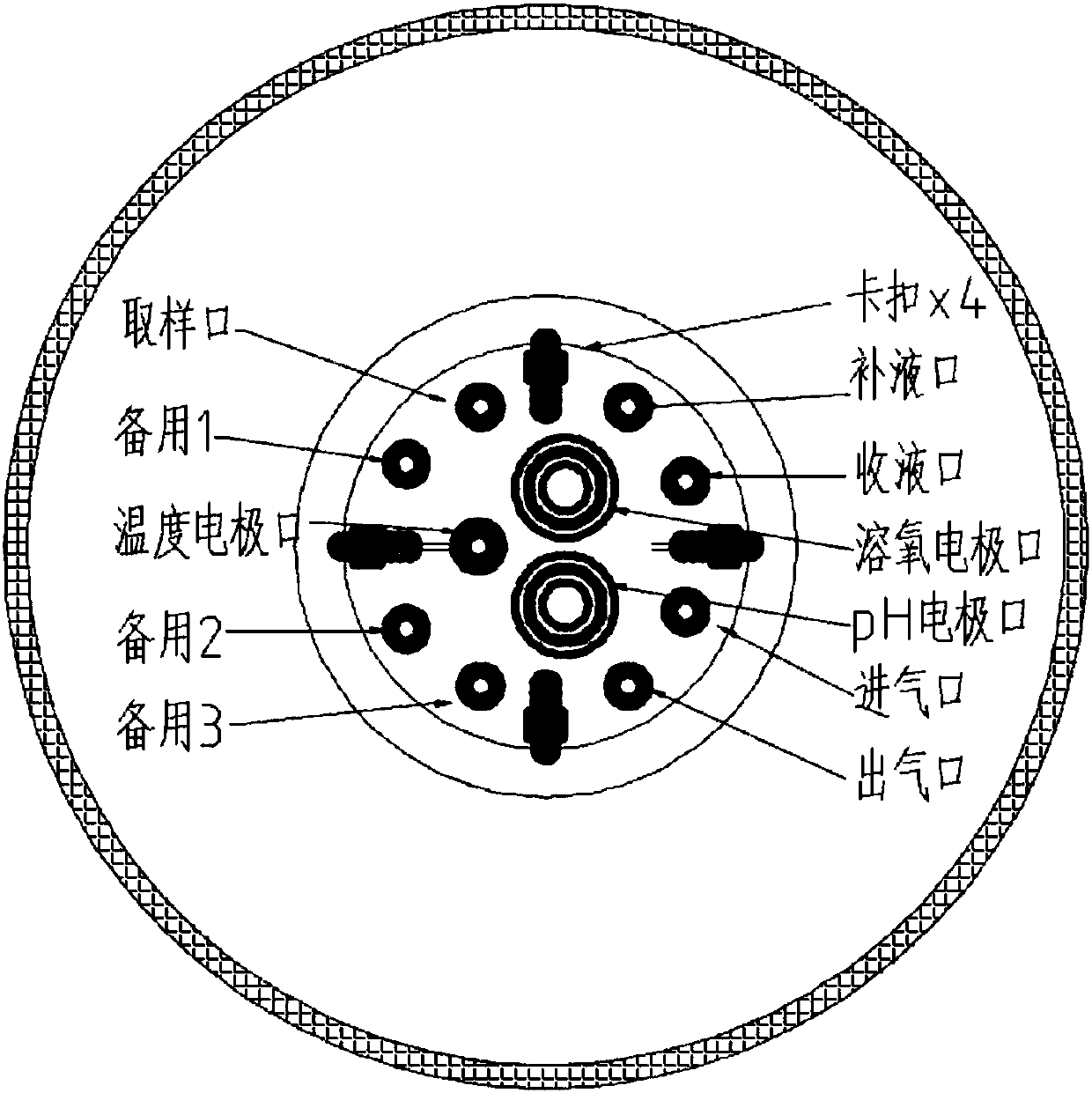

[0049] The parallel bioreactor system according to the embodiment of the present invention is based on the non-bubbling oxygen transfer mechanism. Several culture containers with inverted truncated conical (inverted frustum-shaped) inner chambers are placed on the same platform (shaking plate), and the platform passes The oscillator is driven to realize eccentric oscillation operation. In some embodiments, the parameter control of each culture container can be controlled by an independent CPU and actuator, and data such as records and reports are relatively independent, and the cell culture microenvironment such as pH, dissolved oxygen and nutrients can be precisely regulated. A disposable culture bag with a matching shape and structure is built into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com