CFB boiler tertiary air center cylinder

A secondary air and boiler technology, applied in the field of central cylinder, to prolong the service life and improve the combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

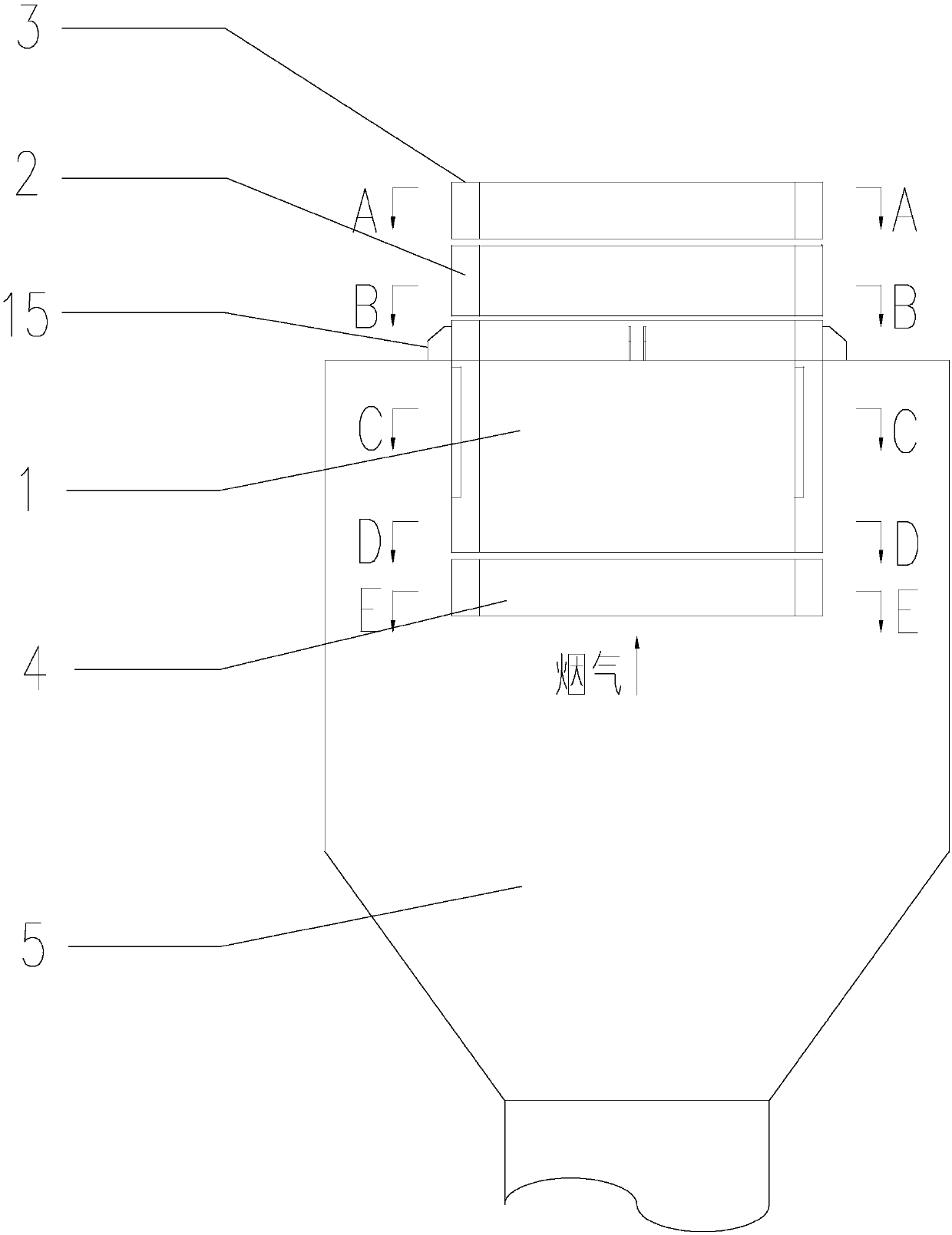

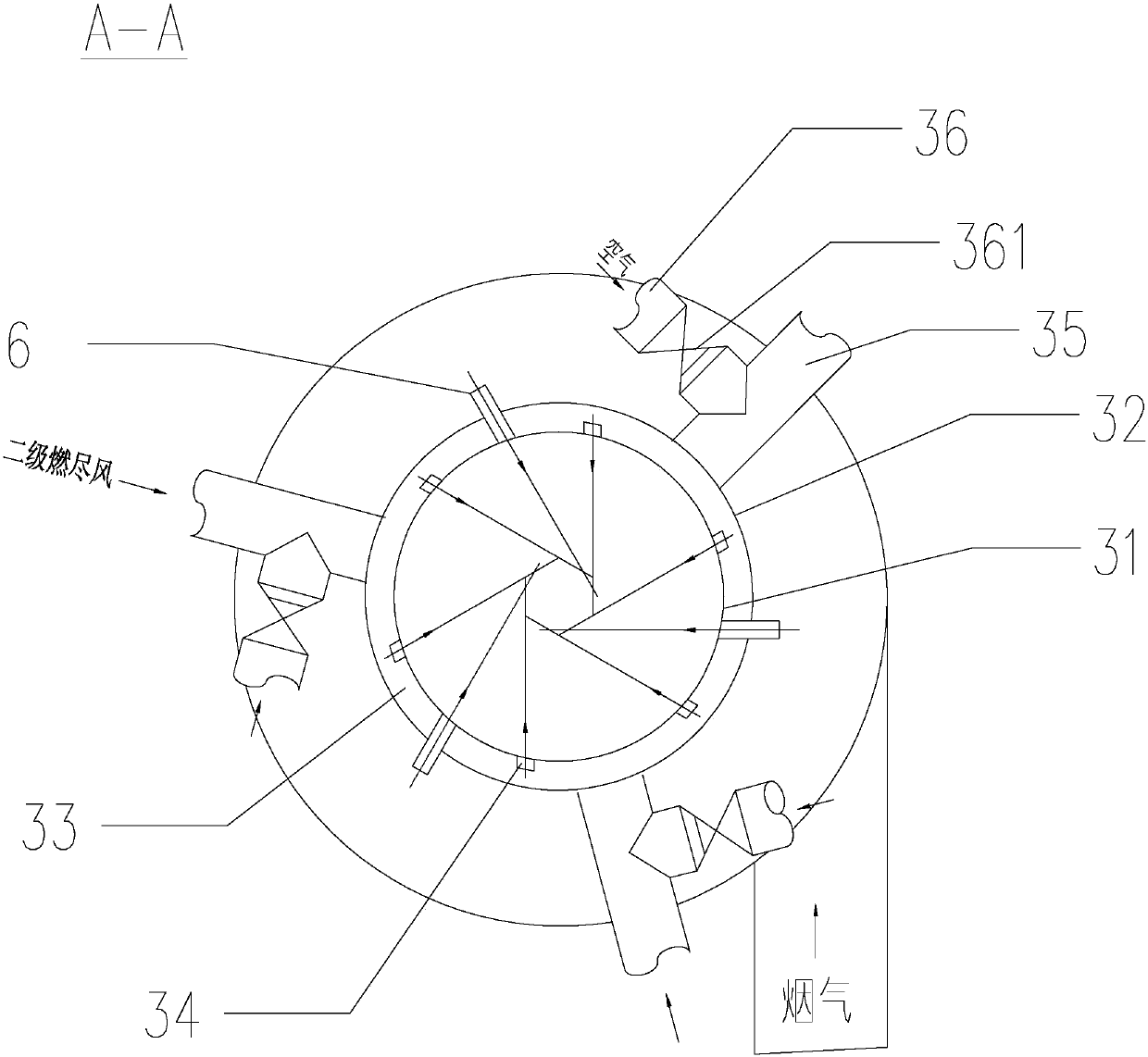

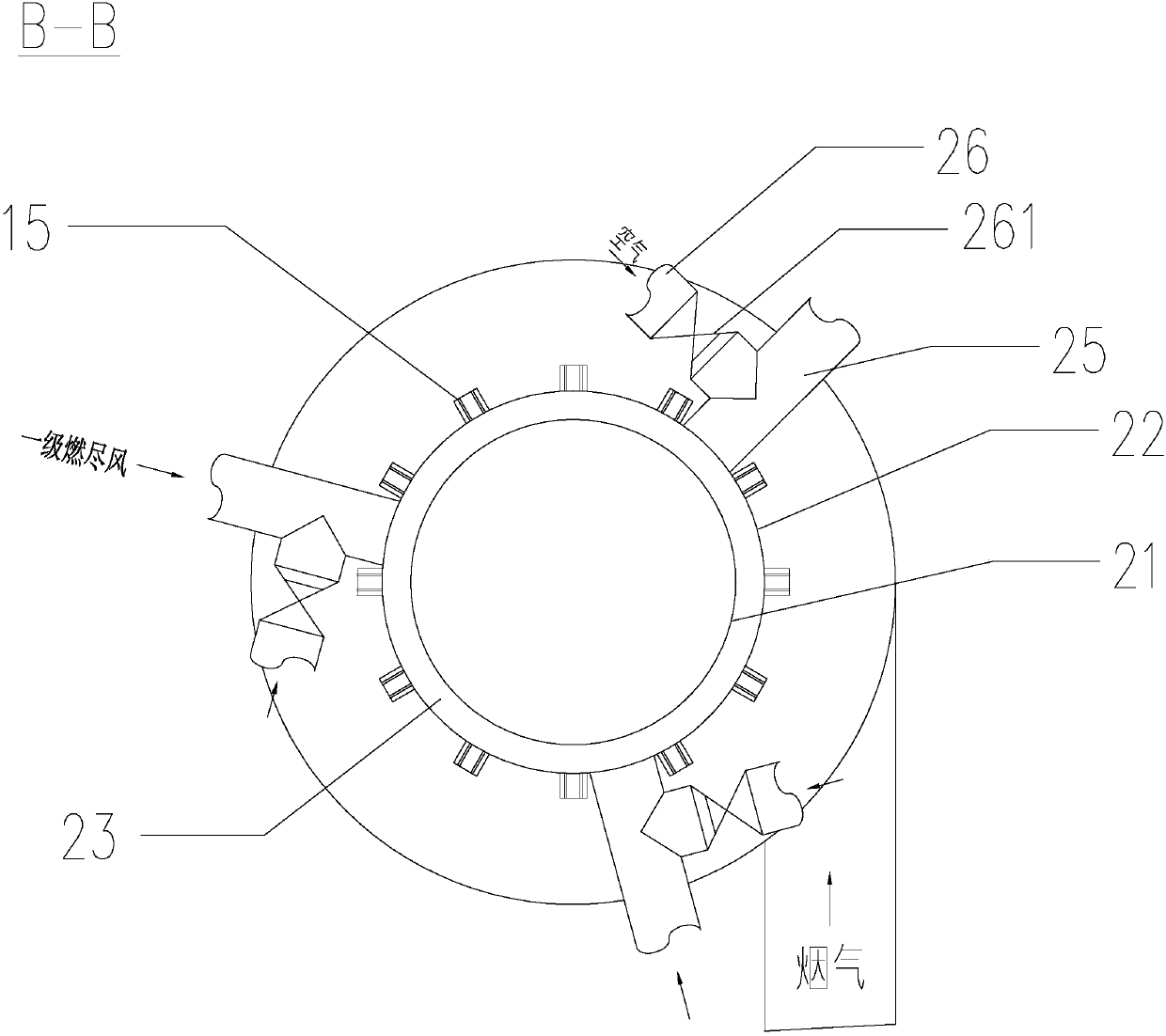

[0040] The invention protects a CFB boiler tertiary air central cylinder device, which is arranged at the outlet of the cyclone separator 5 . The central cylinder is a hollow cylinder wall, which includes an inner wall and an outer wall, and the air supply cavity is between the two. The air supply cavity is closed up and down, and the air duct is connected to the cylinder wall. The inner side of the wall is the flue for the flue gas to rise.

[0041] Generally speaking, because the current production process is not convenient to cast each layer of the central cylinder in one piece, the above-mentioned division of the central cylinder into multiple layers is convenient for transportation and installation.

[0042] The central cylinder includes a central cylinder body 1 , a first bellows 2 at the outlet end connected to the top of the central cylinder body 1 , and an inlet bellows 4 connected to the bottom end of the central cylinder body 1 .

[0043] combine figure 1 and Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com