Biomass fuel heating furnace

A biomass fuel and heating stove technology, applied in the field of stoves, can solve the problems of low thermal efficiency and achieve the effects of improving thermal efficiency, reducing dust, and reducing maintenance and cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

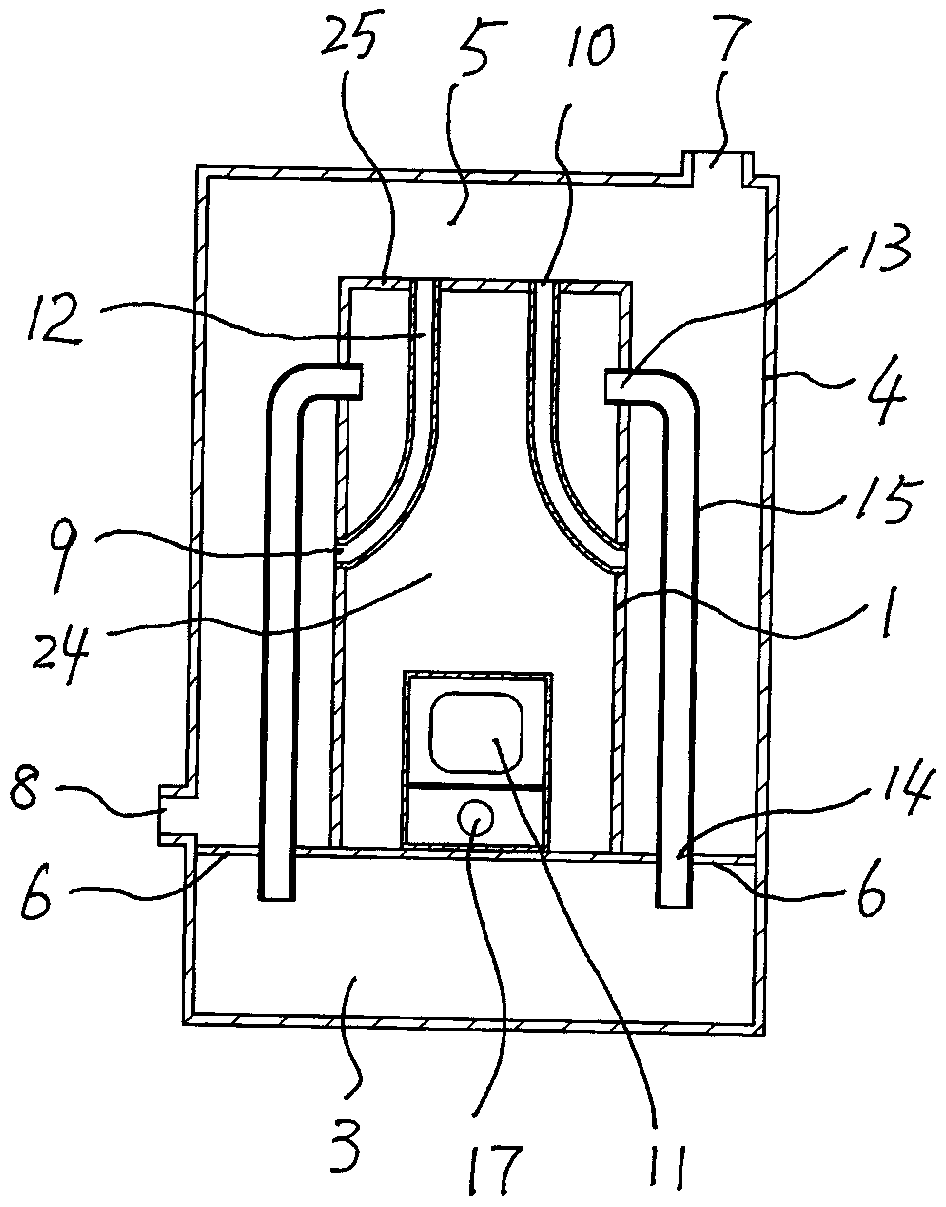

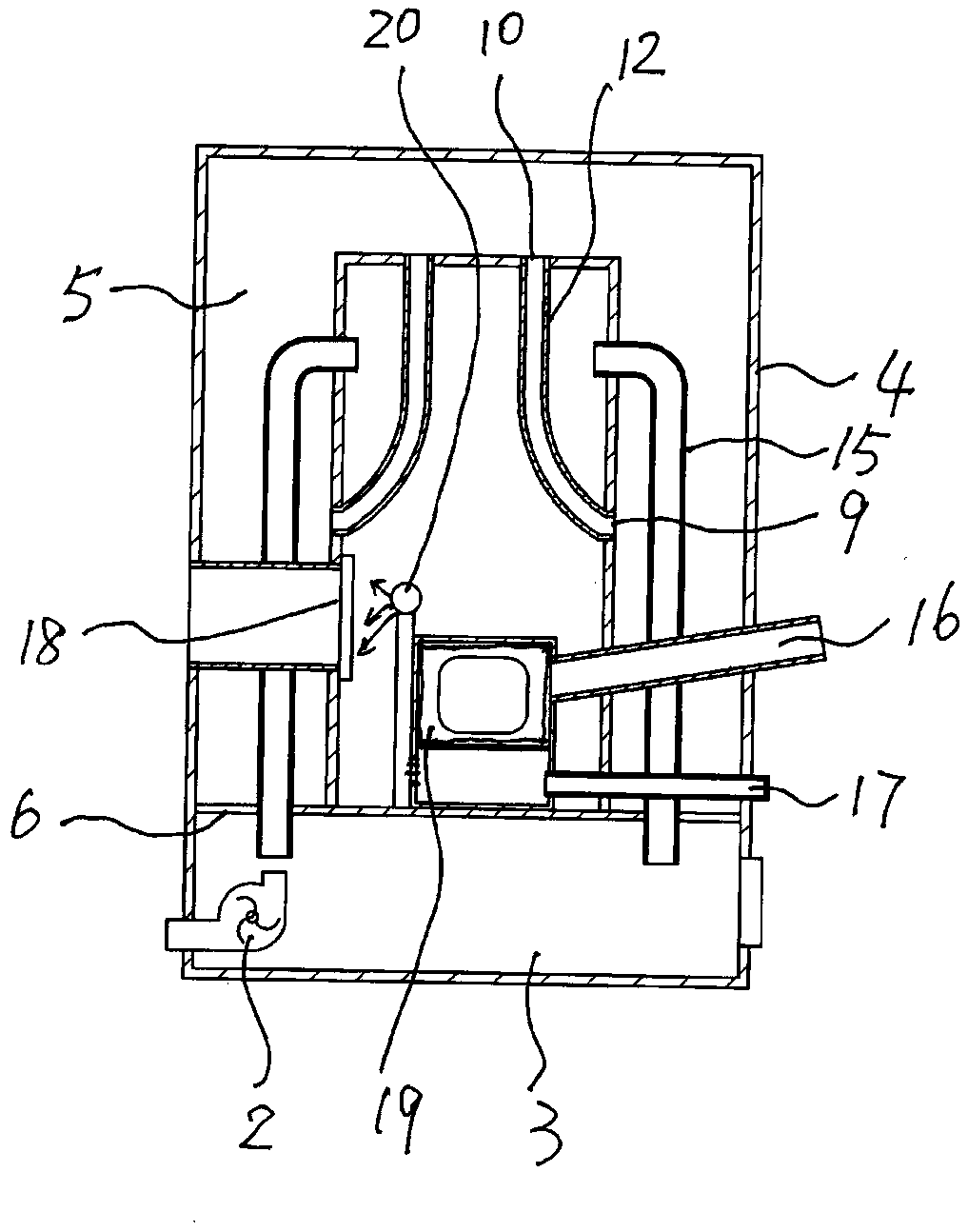

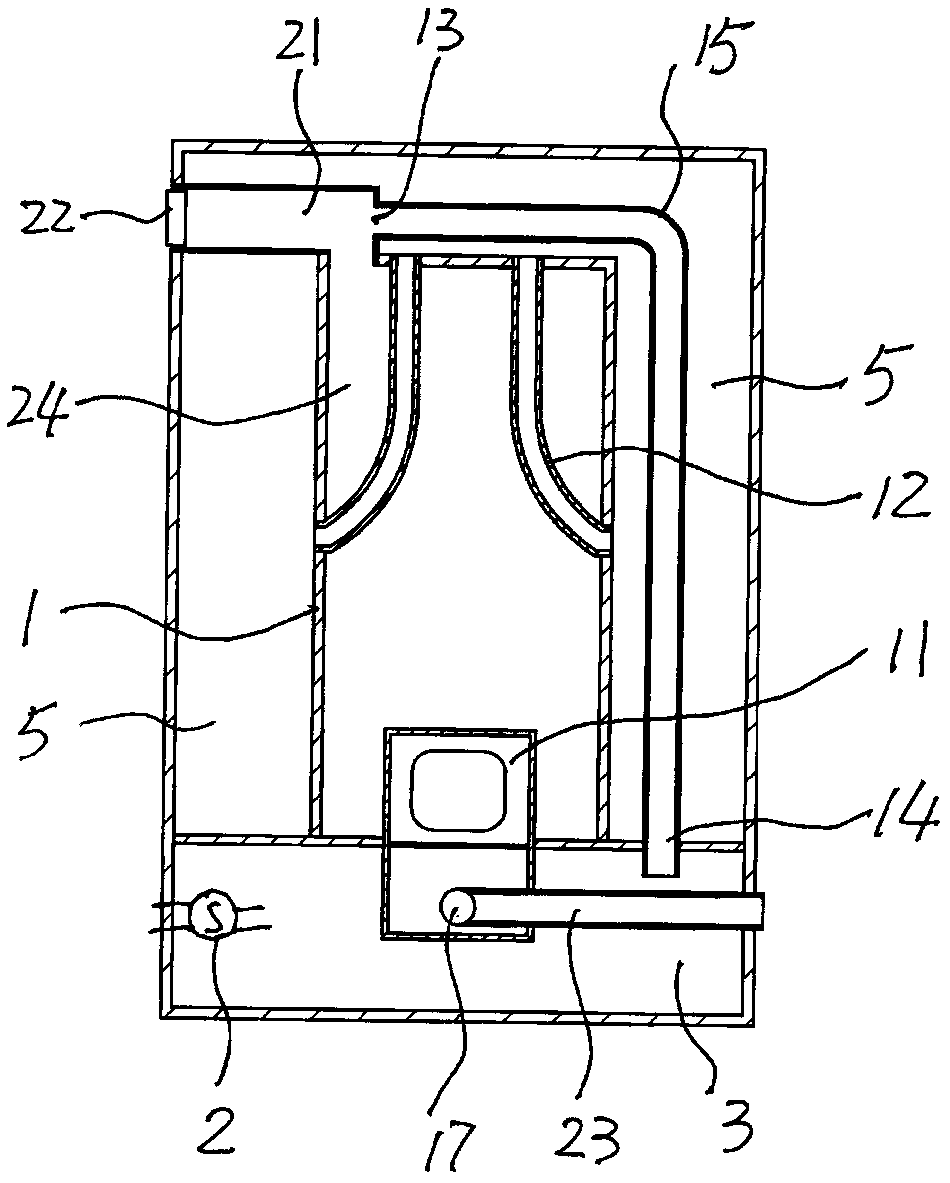

[0025] The structure and working principle of a biomass fuel heating stove provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 , 2 Shown is a schematic structural diagram of a biomass fuel heating furnace provided by the invention. The structure constituting the biomass fuel heating furnace includes a furnace body 1 provided with an air inlet channel 17 and a biomass particle fuel feed port 16 on its furnace wall, and a combustion chamber 11 is arranged in the hearth of the furnace body; The bottom of the bottom of the smoke exhaust fan 2 is fixedly provided with the bottom smoke passage box 3; the outside of the above-mentioned furnace body is provided with a sealed outer shell 4, which forms a water tank 5 between the outer shell and the furnace body, and the water tank and the above-mentioned bottom smoke passage box The body 3 is isolated by the connecting plate 6; the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com