Optimization method of ladle scheduling problem

A scheduling problem and optimization method technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as repair and adjustment procedures considering thermal energy loss from a global perspective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

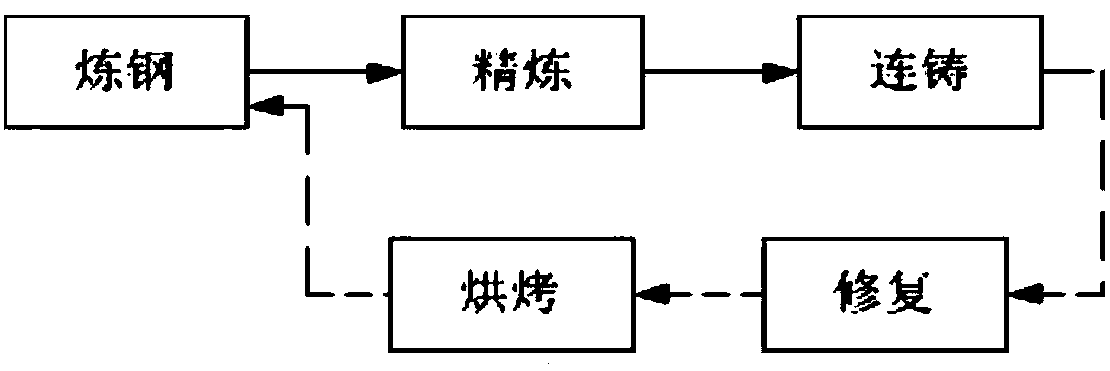

[0030] The invention provides an optimization method for a ladle scheduling problem. Problem introduction: In steelmaking-continuous casting production, molten steel sequentially passes through steelmaking, refining and continuous casting production processes according to the tapping plan. The time for the ladle to serve a furnace of molten steel is from the beginning of tapping in the converter or electric furnace to the end of casting. After pouring, the ladle is sent to the corresponding slag dumping station for slag dumping, and then sent to the turntable, where it is repaired by sand blowing, water outlet replacement and slide plate replacement. The processed empty ladle can be directly sent to the converter or electric furnace to receive molten steel, or to the The fast baking position is waiting to receive molten steel, or go to the baking position for baking to prepare to receive molten steel. figure 1 The turnover process of the ladle in the steelmaking-continuous cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com