A kind of greening device and method for removing raw tobacco

A technology for filling tobacco and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of affecting the taste of tobacco leaves, wasting tobacco leaf resources, economic losses, etc., and achieves the effects of improving ventilation effect, facilitating operation, and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

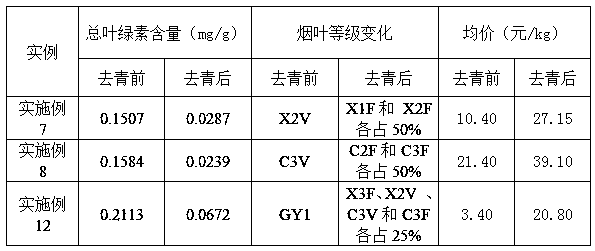

Embodiment 1

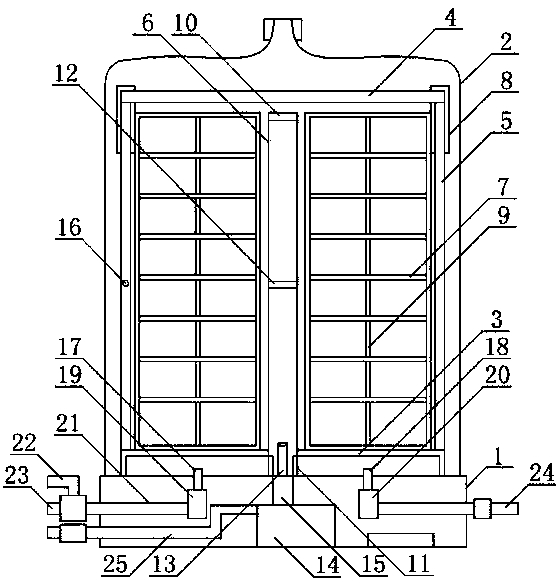

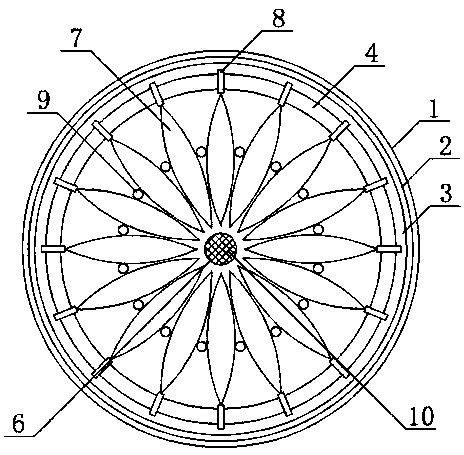

[0042] The greening removal method of the former tobacco greening removal device comprises the following steps:

[0043] (1) Tobacco loading: put the tip of the Qingyuan tobacco leaf towards the air conditioning tube, and the base of the tobacco leaf towards the sealed bag, stacking layers on each tobacco loading layer of the tobacco rack, and multiple tobacco racks to form the air The regulating pipe is the center and is arranged in a circular array pattern. The total smoke capacity of all the smoke racks is 50kg, and it is sealed after the smoke is filled;

[0044] (2) Stacking: Stacking for 10 days under the conditions of ambient temperature 36°C, ambient humidity 16%, and ambient oxygen concentration 1%.

Embodiment 2

[0046] The greening removal method of the former tobacco greening removal device comprises the following steps:

[0047] (1) Tobacco loading: put the tip of the Qingyuan tobacco leaf towards the air conditioning tube, and the base of the tobacco leaf towards the sealed bag, stacking layers on each tobacco loading layer of the tobacco rack, and multiple tobacco racks to form the air The regulating pipe is the center and is arranged in a circular array pattern. The total smoke capacity of all the smoke racks is 200kg, and it is sealed after the smoke is filled;

[0048] (2) Stacking: Stacking for 30 days under the conditions of ambient temperature 40°C, ambient humidity 19%, and ambient oxygen concentration 3%.

Embodiment 3

[0050] The greening removal method of the former tobacco greening removal device comprises the following steps:

[0051] (1) Tobacco loading: put the tip of the Qingyuan tobacco leaf towards the air conditioning tube, and the base of the tobacco leaf towards the sealed bag, stacking layers on each tobacco loading layer of the tobacco rack, and multiple tobacco racks to form the air The regulating pipe is the center and is arranged in a circular array pattern. The total smoke capacity of all the smoke racks is 125kg, and it is sealed after the smoke is filled;

[0052] (2) Heaping: Heaping for 20 days at an ambient temperature of 38°C, an ambient humidity of 17%, and an ambient oxygen concentration of 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com