A method for classifying metal powder

A metal powder, grading disc technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc., to achieve the effects of large processing capacity, high degree of automation, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

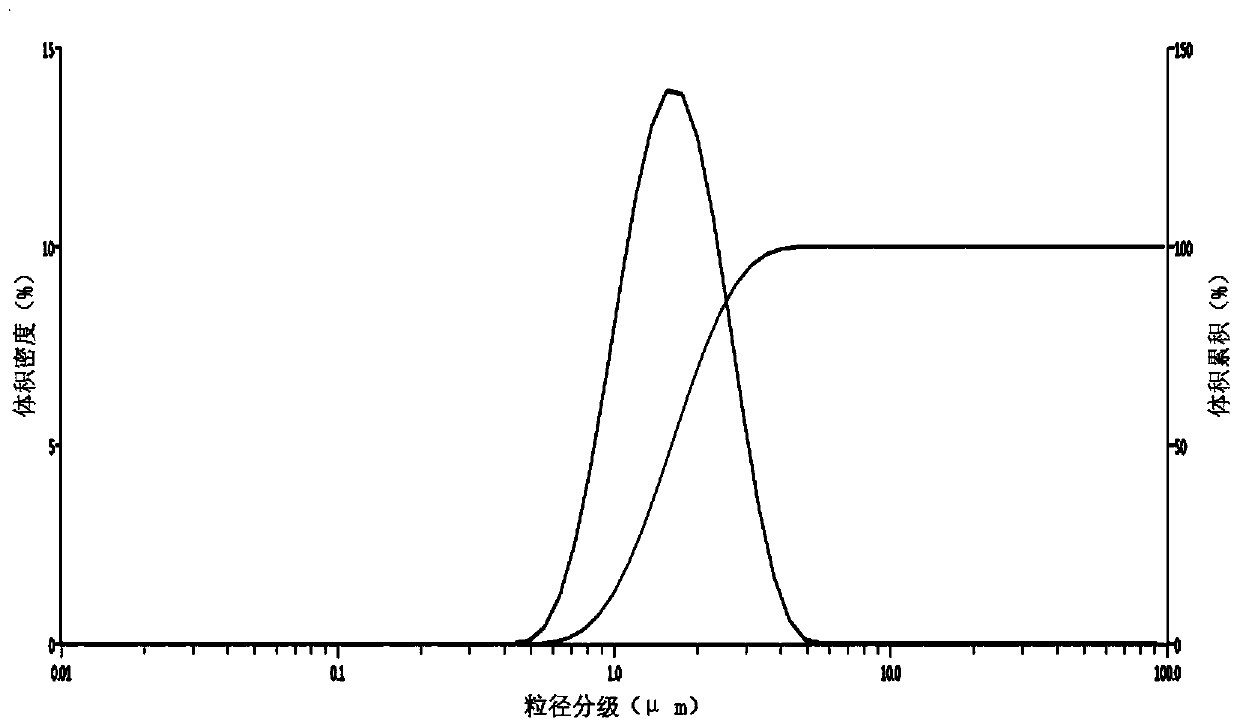

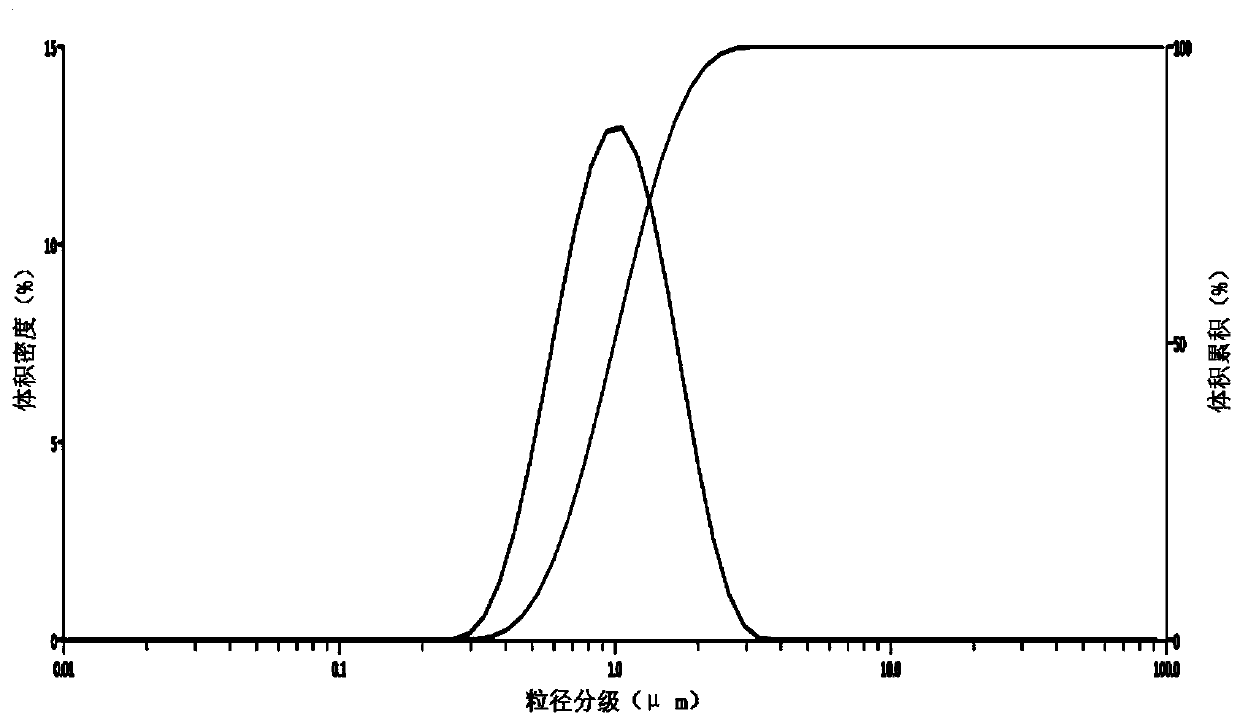

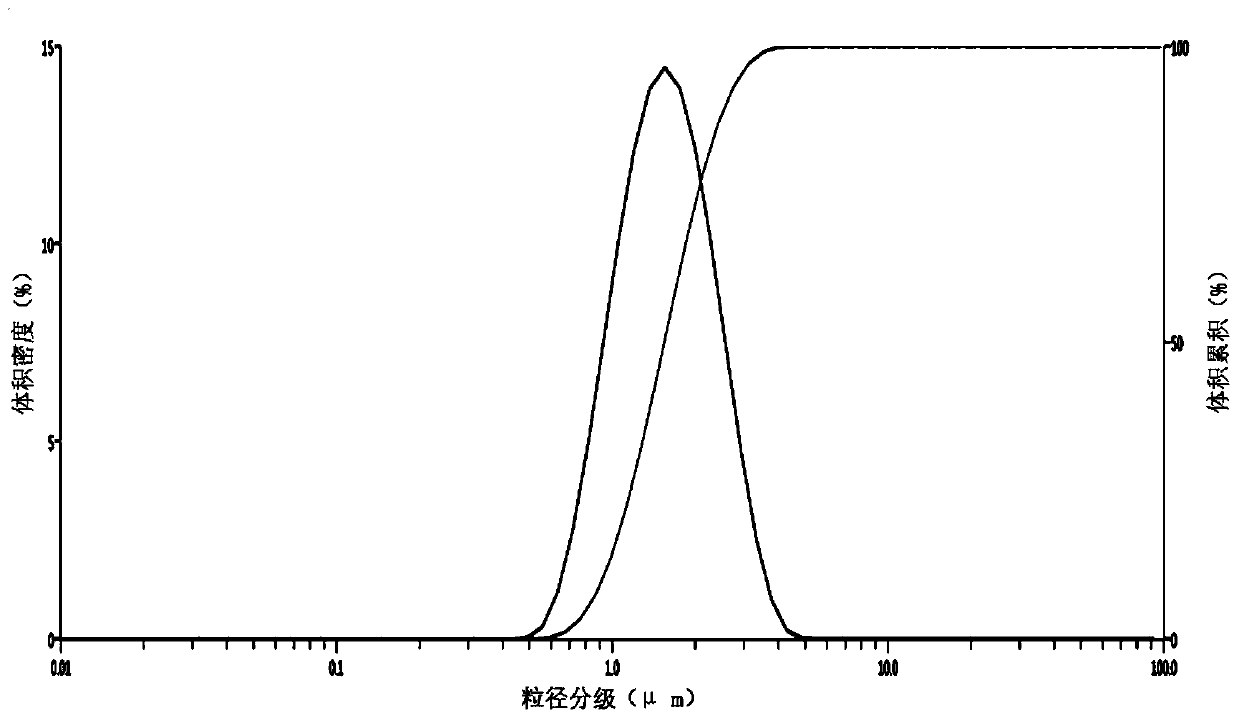

Embodiment 1

[0051] Take 20 kg of crushed and dispersed spherical SMT001 silver powder and add it to the classification and collection device through the automatic feeder, use compressed air as the high-pressure air source, the pressure is 3 kg, the feeding speed is 10 kg / hour, and the return air volume of the induced draft fan is 70% Get fine powder, medium powder, coarse powder verification effect: a:PSD data and particle size distribution figure ( Figure 1~4 ); b: SEM photos: SMT001 series silver powder raw materials, SMT001-fine powder, SMT001-medium powder, SMT001-coarse powder ( Figure 5-8 ); Through electron microscope photos and PSD analysis, it can be clearly seen that the particle size distribution of the spherical silver powder after treatment is very consistent, and the dispersion is improved at the same time.

[0052] Table 1: PSD data statistics and distribution diagrams before and after S3 series silver powder treatment in embodiment 1:

[0053] category D10 D...

Embodiment 2

[0055] Take 100 kg of dispersed and crushed S6 series spherical silver powder and add it to the classification and collection device through the automatic feeder, using compressed air as the high-pressure air source, the pressure is 6 kg, the feeding speed is 50 kg / hour, and the return air volume of the induced draft fan is 80 %; after classification and collection, get fine powder, medium powder, coarse powder verification effect: a: PSD data and particle size distribution diagram ( Figures 9 to 12 ); b: SEM photos: S6 series silver powder raw materials, S6-fine powder, S6-medium powder, S6-coarse powder ( Figures 13 to 16 ); Through electron microscope photos and PSD analysis, it can be clearly seen that the particle size distribution of the spherical silver powder after treatment is very consistent, and the dispersion is improved at the same time.

[0056] PSD data statistics and distribution diagrams before and after the S6 series silver powder treatment of table 2 embod...

Embodiment 3

[0059] Take 5 kg of dispersed titanium alloy spherical powder and add it to the classification and collection device through the automatic feeder, use nitrogen as the high-pressure air source, the pressure is 4 kg, the feeding speed is 5 kg / hour, and the return air volume of the induced draft fan is 90%. The powder is taken as the following electron microscope photo: SEM3-titanium alloy raw material powder electron microscope photo ( Figure 17 ), the medium powder obtained after SEM3-grading and collection ( Figure 18 ); Through the electron microscope photos, it can be clearly seen that the particle size distribution of the material after treatment is very consistent, and its dispersibility is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com