Case drilling and tapping integrated type automatic device and working method thereof

An automated equipment and integrated technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of lack of integrated improvement of punching and tapping, lack of consistency, and affect product quality, etc., and achieve breakthroughs Bottleneck of production capacity beat, saving of processing procedures, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

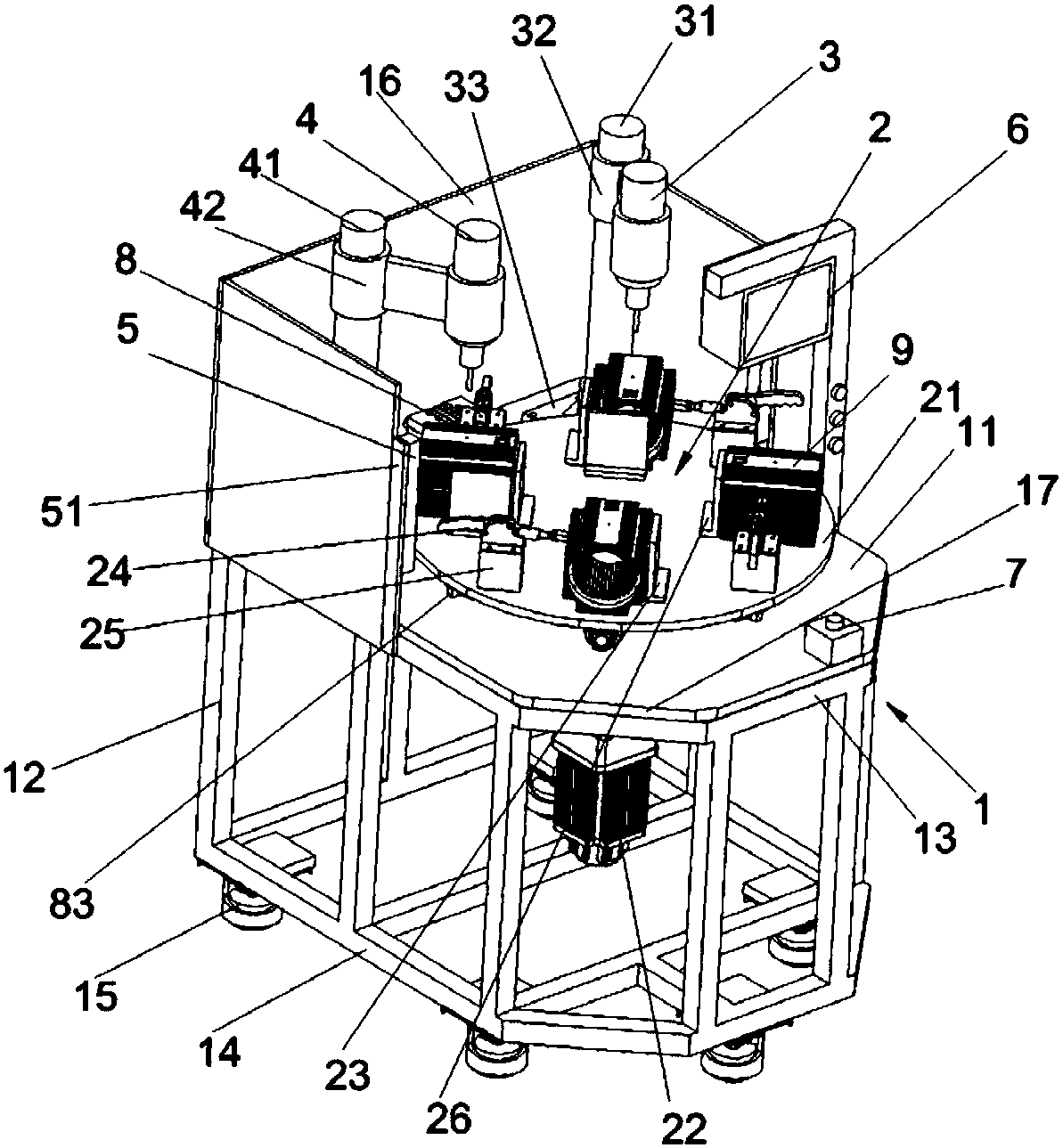

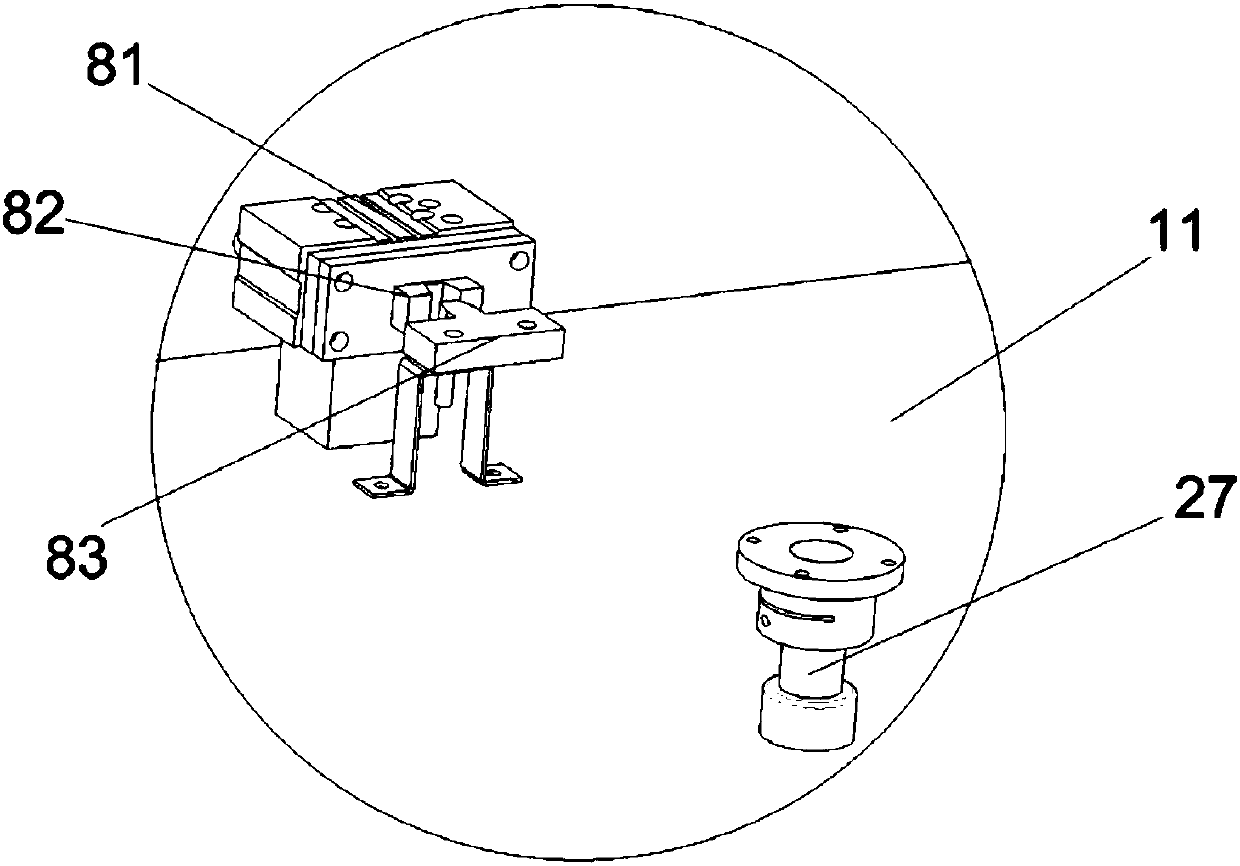

[0033] Such as figure 1 and 2As shown, an integrated automation equipment for casing drilling and tapping includes a frame 1 , a drilling power head 3 and a tapping power head 4 . Frame 1 comprises support platform 11 and several support feet 12, and workpiece rotation mechanism 2 is installed on support platform 11, and workpiece rotation mechanism 2 comprises rotary platform 21 and the servomotor 22 that drives rotary platform 21 to rotate, and servomotor 22 is fixed on the support platform 11, the center of the rotary table 21 is connected with the motor shaft of the servo motor 22 through the rotating shaft 27, and the support table 11 is provided with four stations, which are respectively two clamping stations, a drilling station and a tapping worker. There are four workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com