Grinding machine tool for drum type brake pad

A technology of brake pads and grinding mechanism, which is applied to the parts of grinding machine tools, grinding machines, grinding drive devices, etc. The effect of labor intensity, avoidance of re-cleaning, and concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

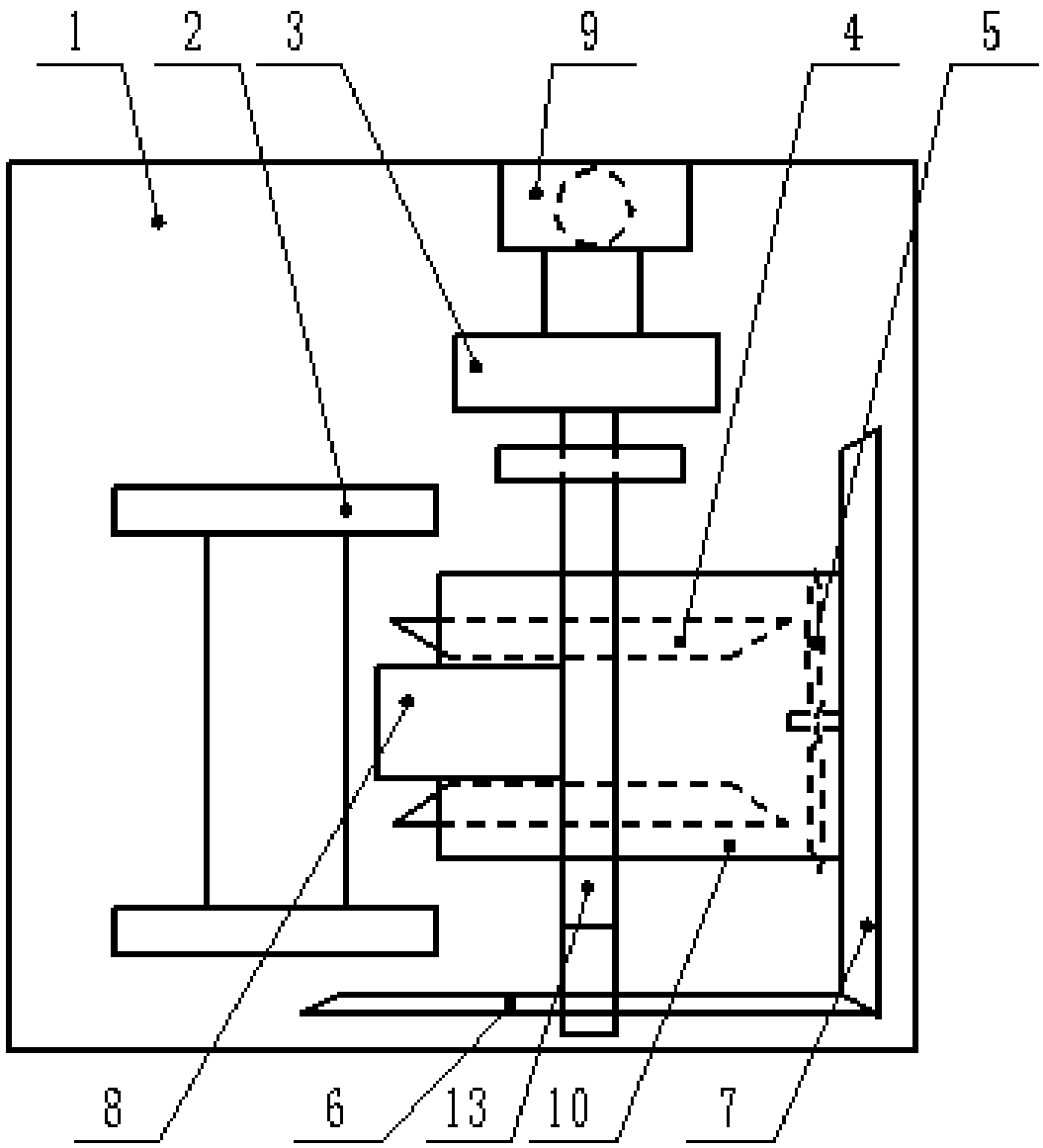

[0023] Drum brake pad grinding machines such as figure 1 As shown, it includes a bed body 1 of a machine tool, on which a base 2 for fixing drum brake pads is installed, and also includes a grinding mechanism cooperating with the base 2 and a horizontal telescopic cylinder 9 for controlling the movement of the grinding mechanism. The horizontal telescopic cylinder 9 is welded on the bed body 1 by a support.

[0024] The grinding mechanism includes a grinding unit and a negative pressure unit for processing waste from the grinding unit. The grinding unit includes a motor 3, which is welded to the output shaft of the horizontally telescopic cylinder 9, and the output shaft of the motor 3 is coaxially welded with a grinding wheel unit 4, and each grinding wheel unit 4 has a cover 10 outside, and the left side of the cover 10 has an opening , The grinder unit 4 is composed of two grinders with a gap between the two grinders. In this embodiment, the grinder is provided with a cha...

Embodiment 2

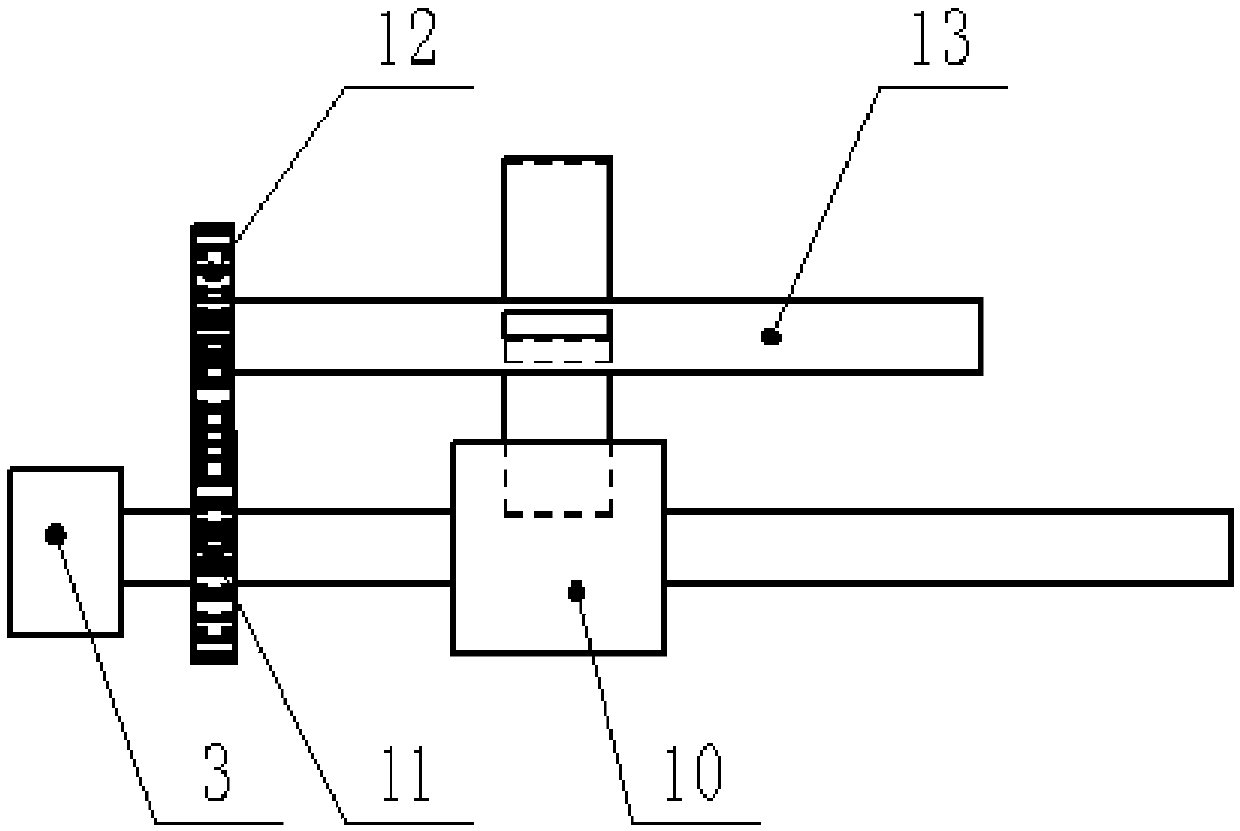

[0028] The difference between this drum type brake pad grinding machine tool and Embodiment 1 is: (1) In this embodiment, grinding mechanisms are symmetrically provided on both sides of the base 2 . (2) The side where the fan 5 is away from the grinder and the contact side of the drum brake pad is connected with a guide pipe. (3) if figure 2 As shown, the number of blocking pieces 8 is four, and they are uniformly welded on the rotating shaft 13 in the circumferential direction. Compared with the single-side grinding of the grinding mechanism, the two grinding mechanisms in this scheme can simultaneously grind the drum brake pads, making the grinding efficiency higher. After the guide tube makes the negative pressure generated by the fan 5 act on the waste, the guide tube concentrates the waste to avoid re-cleaning of the waste in the later stage, which reduces labor intensity and improves efficiency. The circumferentially uniform baffles 8 can be rotated sequentially with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com