Synchronous hoisting device for steel column casing rack alternate support type steel platform and tower crane and hoisting method of synchronous hoisting device

A technology of synchronous lifting and steel platform, applied in construction, crane, building construction, etc., can solve problems such as easy conflict, and achieve the effect of enhancing overall safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

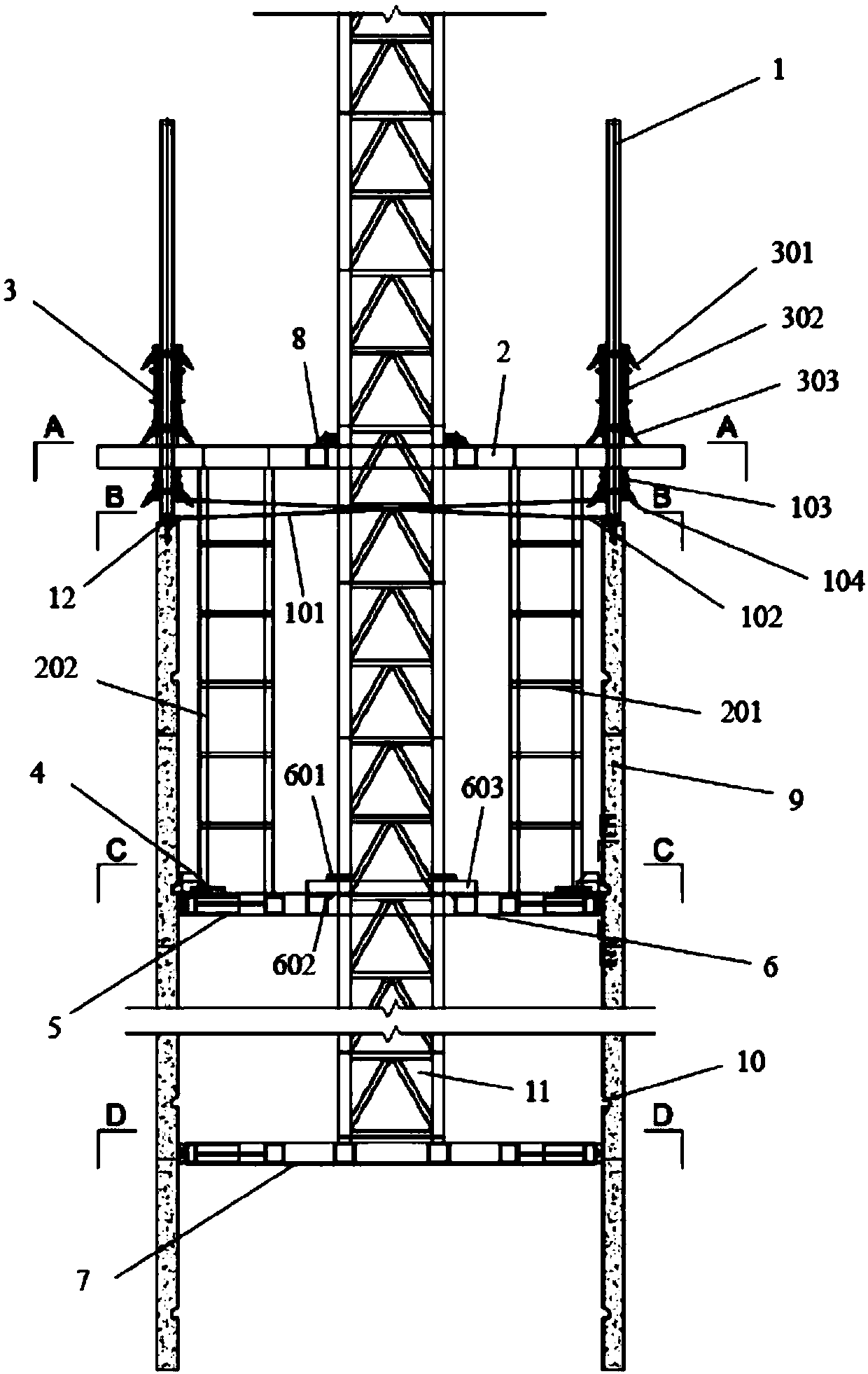

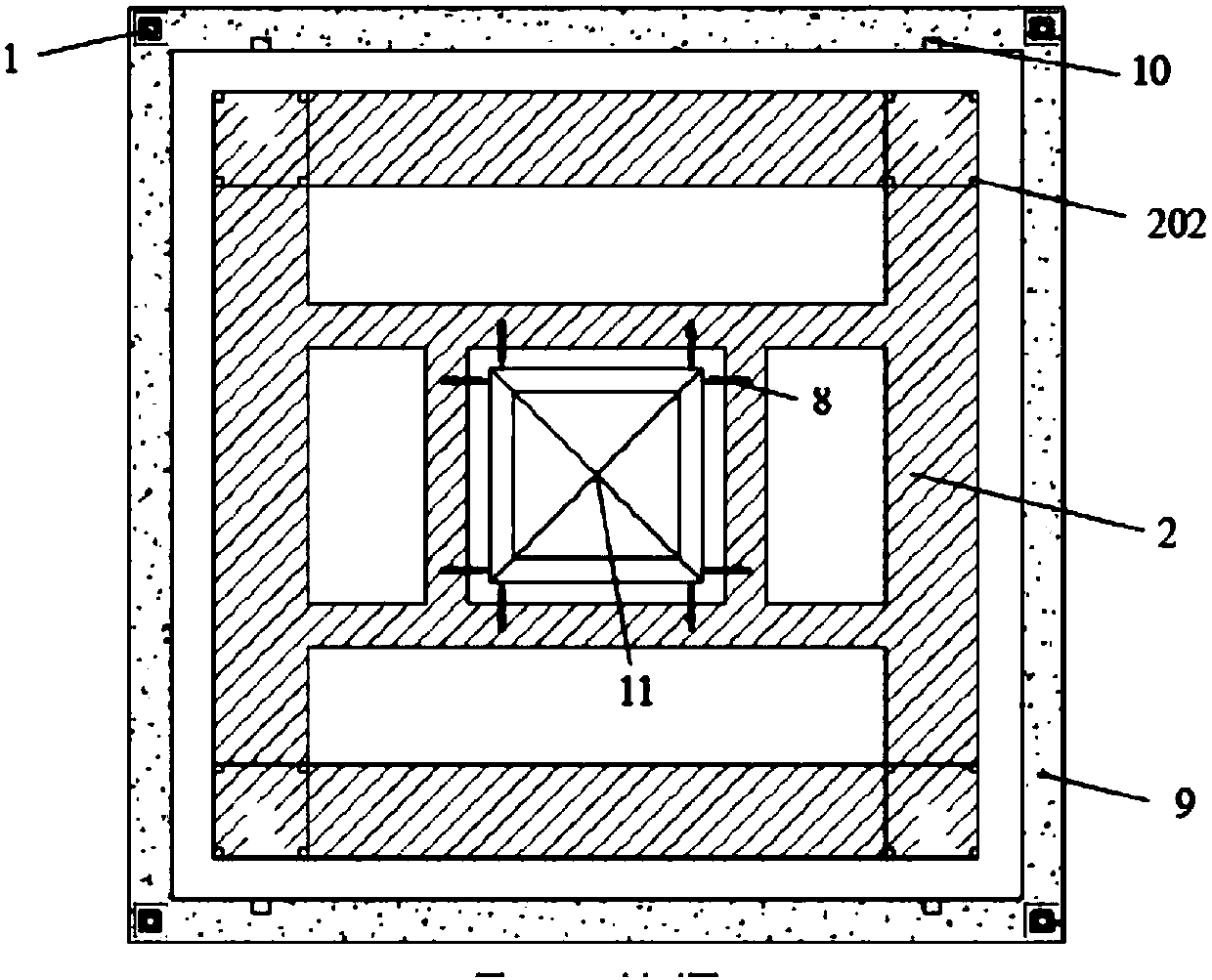

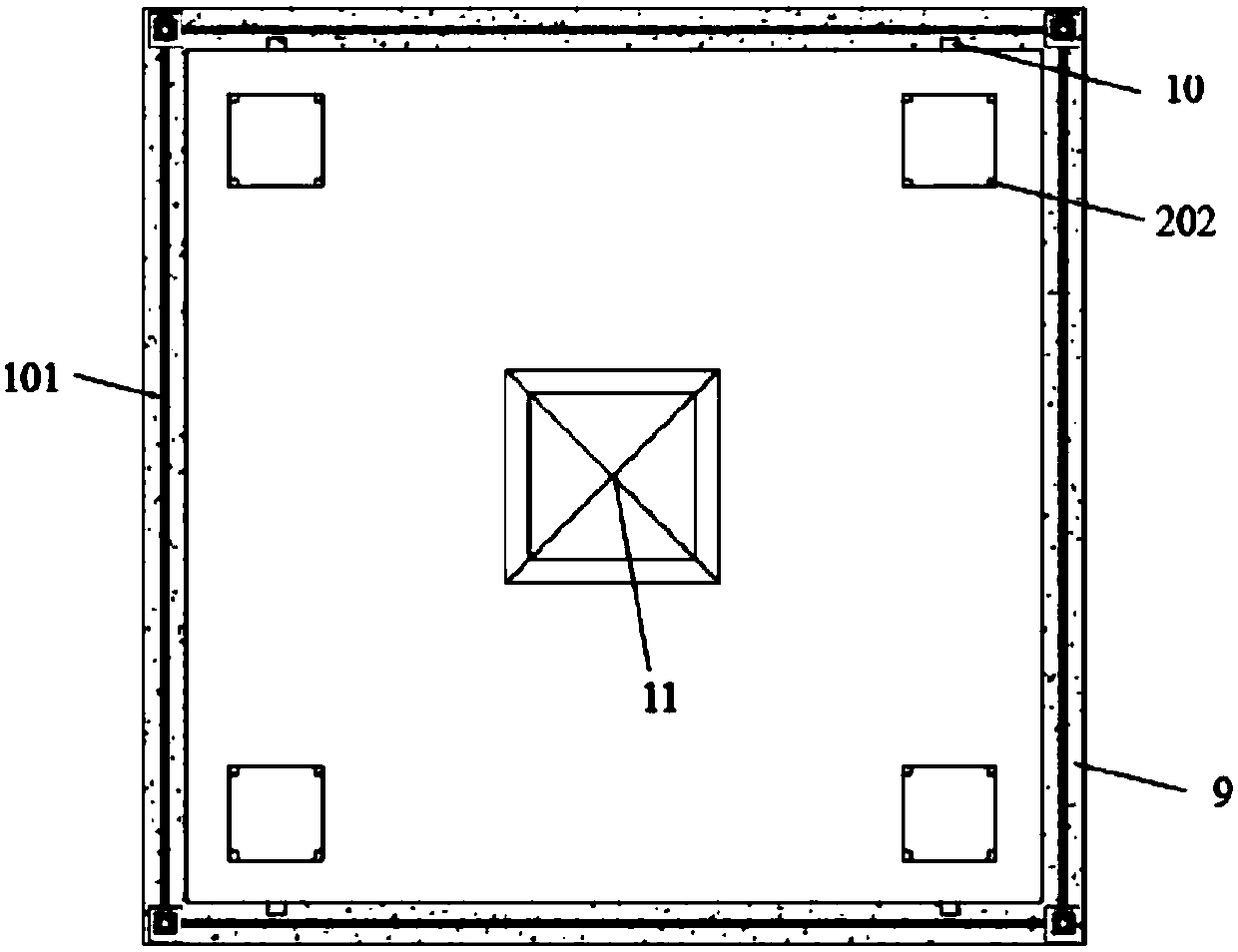

[0054] A synchronous lifting device for steel platforms and tower cranes alternately supported by steel columns and tube frames, including steel platforms, tower cranes, hoisting steel columns 1 and a lifting power system; 201. The overall lifting beam 6 and the horizontal support beam 7, the steel platform top beam, the cylinder frame support, the overall lifting beam and the horizontal support beam are arranged sequentially from top to bottom; the steel platform top beam 2 is provided with a horizontal limit guide Wheel 8, the guide wheel can selectively resist the tower crane, the tower crane includes a tower crane standard section, the tower crane is connected to the integral lifting beam 6, and the lower part of the tower crane is fixedly connected to the horizontal support beam 7; The lifting power system is used to provide lifting power to move the steel platform along the lifting steel column.

[0055] Specifically, by connecting the tower crane with the steel platform...

Embodiment 2

[0075] A synchronous lifting method using the above synchronous lifting device, its implementation process can be decomposed into: initial state, lifting process, lifting in place, lifting the lifting steel column back, and lifting completed.

[0076] Specifically, the above synchronous promotion method specifically includes the following steps:

[0077] Step 1: In the initial state, complete the preparatory work before lifting; preferably, confirm that the tower crane is in a non-working state and check whether each component has the lifting conditions, ensure that the hydraulic telescopic guide roller 5 is tightly pressed against the core tube structure, and the steel column is lifted below, Do a good job of fixing the lifting steel column and the shear wall, connect the lifting steel column and the wall, and tighten the horizontal limit guide wheel of the top beam of the steel platform with the standard section of the tower body of the tower crane to limit the horizontal dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com