Environment-friendly degradable well drilling fluid anti-collapse blocking agent and method for preparing same

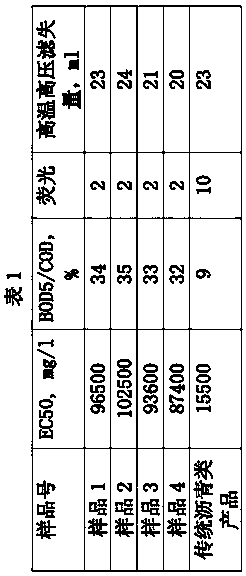

A technology of drilling fluid and plugging agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of toxicity, non-environmental protection, refractory degradation, high fluorescence level, etc., and achieves simple preparation method, good plugging performance, The effect of low fluorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: The environmentally friendly and degradable drilling fluid anti-slump plugging agent, the raw materials are 50 to 60 parts by weight of plant asphalt, 5 to 10 parts of sodium silicate, 5 to 10 parts of sodium hydroxide, and 5 parts of lignite to 10 copies, Span-80 5 to 10 copies.

Embodiment 2

[0017] Embodiment 2: The environmentally friendly and degradable drilling fluid anti-slump plugging agent, the raw materials are 50 or 60 parts by weight of vegetable asphalt, 5 or 10 parts of sodium silicate, 5 or 10 parts of sodium hydroxide, and 5 parts of lignite Or 10 copies, Span-80 5 copies or 10 copies.

[0018] Its raw material component plant asphalt among the above-mentioned embodiment 1 and 2 is the by-product of various vegetable oil refining process, also can be natural plant asphalt, sodium silicate is industrial grade solid or liquid product, sodium hydroxide is industrial grade solid The chemical name of the product, Span-80, is sorbitan glyceride.

Embodiment 3

[0019] Embodiment 3: The environmentally friendly and degradable drilling fluid anti-collapse plugging agent is obtained according to the following steps: the first step, mix and stir the required amount of plant asphalt, Span-80 and water, and heat to 90°C to 95°C ℃, until it dissolves and mixes uniformly, stop heating to obtain material A; in the second step, mix and stir the required amount of sodium silicate, sodium hydroxide, lignite powder and water evenly, and react for 1 to 1.5 hours to obtain material B; in the third step, the obtained material A and material B are evenly mixed to obtain an environmentally friendly and degradable drilling fluid anti-slump plugging agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com