Water-based drilling fluid applicable to salt-gypsum layer and preparation method of water-based drilling fluid

A technology for water-based drilling fluid and salt-gypsum layer, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as anti-calcium ion pollution of drilling fluid, and achieve excellent plugging performance, excellent inhibition, and good carrying capacity. The effect of sand properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

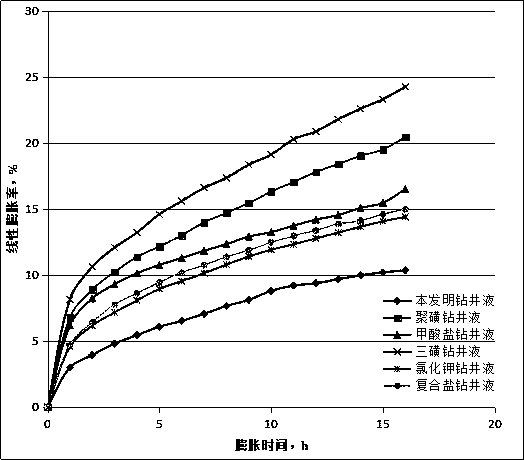

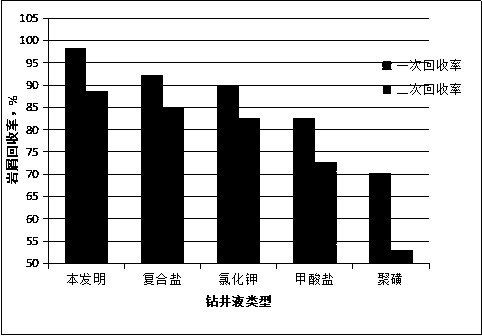

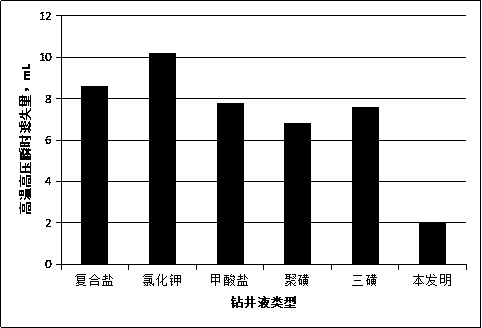

[0045] In order to overcome the problems of dissolution and creep of salt layers, water absorption and swelling of anhydrite, mudstone expansion and dispersion, slurry collapse, plugging of drilling fluid, and anti-calcium ion pollution, the present invention provides a water-based drilling fluid suitable for salt-gypsum layers and its preparation method, one of the purposes of the present invention is to have excellent inhibition and anti-slump performance on the salt-gypsum layer, and effectively solve the problem of well wall stability and loss of return lost circulation caused by dissolution creep of large-section salt-gypsum layer and salt rock collapse. and other technical problems.

[0046] The second object of the present invention is to meet the urgent needs of the Ordovician, Cambrian and Changchengian oil and gas reservoir exploration and development in the Ordos Basin for the production of water-based drilling fluids suitable for salt-gypsum formations.

[0047] Th...

Embodiment 2

[0071] A water-based drilling fluid suitable for salt-gypsum layers consists of the following components by weight percentage:

[0073] Tackifier 0.5%;

[0074] Fluid loss additive 2.0%;

[0075] Plugging agent 1.0%;

[0077] Soda ash 0.5%;

[0078] Ion complexing agent 0.1%;

[0080] Barite 5%;

[0081] The balance is water.

[0082] The blocking agent is a polymer synthesized by butadiene, styrene and 2-acrylamido-2-methylpropanesulfonic acid, and the mass percent of the three is butadiene: styrene: 2-acrylamide- 2-Methylpropanesulfonic acid=3:1:1.

[0083] The thickener is one of polyanionic cellulose PAC-HV and carboxymethyl cellulose CMC-HV or a mixture of two of them.

[0084] The fluid loss control agent is one or a mixture of sulfonated phenolic resin type II, polyanionic cellulose PAC-LV, and carboxymethyl cellulose CMC-LV.

[0085] The ion-complexing agent is et...

Embodiment 3

[0090] A water-based drilling fluid suitable for salt-gypsum layers consists of the following components by weight percentage:

[0092] Tackifier 1.5%;

[0093] Fluid loss additive 10.0%;

[0094] Plugging agent 2.0%;

[0095] Sodium hydroxide 0.3%;

[0096] Soda ash 3.0%;

[0097] Ion complexing agent 0.3%;

[0099] Barite 15%;

[0100] The balance is water.

[0101] The blocking agent is a polymer synthesized by butadiene, styrene and 2-acrylamido-2-methylpropanesulfonic acid, and the mass percent of the three is butadiene: styrene: 2-acrylamide- 2-Methylpropanesulfonic acid=3:1:1.

[0102] The thickener is one of polyanionic cellulose PAC-HV and carboxymethyl cellulose CMC-HV or a mixture of two of them.

[0103] The fluid loss control agent is one or a mixture of sulfonated phenolic resin type II, polyanionic cellulose PAC-LV, and carboxymethyl cellulose CMC-LV.

[0104] The ion-complexing agent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com